|

|

|

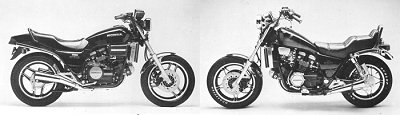

Choose your flavor. Considered enough of a sport bike to be found on racetracks until the Interceptor emerged, the Sabre was a pretty nice bike. In fact I raced one. For a more relaxed riding experience, the superior-selling Magna was offered. The running gear were virtually identical.

|

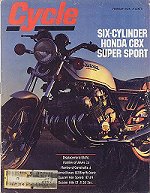

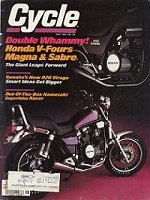

During the period of the V4s' introduction and early history, I held a post with Honda's U.S. headquarters, which was at that time in Gardena (though now in Torrance), California. Among my duties was the daily interaction with dealers, service reps, engineers, product liability people, and the buying public; essentially, all of the players in the drama that was to characterize the introduction of Honda's new V4s. It was an interesting job, and this was an interesting time.  Honda had just experienced a renewal of sorts. Thanks in part to Kawasaki's Z1, a lot of Honda's performance persona had faded, and apparently someone at the Big H didn't like that. The company made an effort to regain a sporting reputation, and with its reentry into world roadracing, the emergence of the NR500, NS750, CBX, and CX500 Turbo, as well as Freddie Spencer's success with the CB750F-based 1025cc production racers, there was more than advertising hype in Honda's new slogan, "Follow the Leader." Big Red was cooking once again. Honda had just experienced a renewal of sorts. Thanks in part to Kawasaki's Z1, a lot of Honda's performance persona had faded, and apparently someone at the Big H didn't like that. The company made an effort to regain a sporting reputation, and with its reentry into world roadracing, the emergence of the NR500, NS750, CBX, and CX500 Turbo, as well as Freddie Spencer's success with the CB750F-based 1025cc production racers, there was more than advertising hype in Honda's new slogan, "Follow the Leader." Big Red was cooking once again.

The new V4 streetbikes were released against this heady backdrop of success, and they were impressive monuments to Honda's engineering prowess. The motopress gushed with enthusiasm. Honda threw private company parties at Disneyland and on the Queen Mary, and it seemed as if the euphoria would never end. But there was trouble in paradise. Before the scheduled March intro Honda had to convince Can-Am to rename its new Sabre dirt bike. Whatever the agreement reached between the two companies, virtually overnight the Canadian company's offering became the Sonic. And that was just the first of challenges. The new V4 streetbikes were released against this heady backdrop of success, and they were impressive monuments to Honda's engineering prowess. The motopress gushed with enthusiasm. Honda threw private company parties at Disneyland and on the Queen Mary, and it seemed as if the euphoria would never end. But there was trouble in paradise. Before the scheduled March intro Honda had to convince Can-Am to rename its new Sabre dirt bike. Whatever the agreement reached between the two companies, virtually overnight the Canadian company's offering became the Sonic. And that was just the first of challenges.

<

|

|

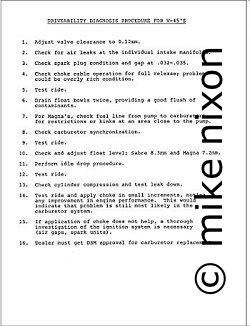

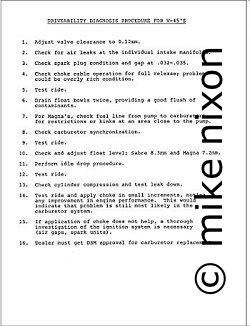

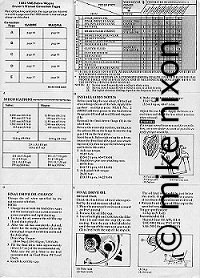

The unofficial field rep circulated checklist. Bringing solutions to bear on the many customer complaints. Proactive, systematic. Click to enlarge.

|

Honda had an engine factory in Hamamatsu. Just before the V4s went into production, automated engine assembly equipment was said to have been put online, and the V4 engine was the first to benefit. The result was engines whose valve clearances were way off. The bike's much-heralded March 1982 arrival in the U.S. was painfully anticlimactic: the machines idled poorly, blued pipes, and stalled unaccountably in traffic. Soon, Honda was earnestly pursuading its dealers to adjust valves it had already, in an unexpected departure from the company's historic policy, informed did not need adjusting before the sale. The dealers were hard to convince. Juggling radiators was a new concept, and most of them had been skipping Honda's mandatory valve adjustment for years.

Before the month was out, Sabres and Magnas were veritable pariahs, as much with the dealers as with the buying public. Field reps learned quickly to anticipate unhappy V4 owners at each stop on their rounds, and were instructed by the home office to give each dealer a list of things the

|

|

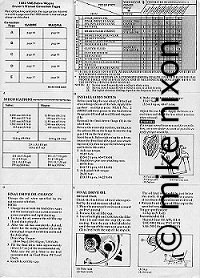

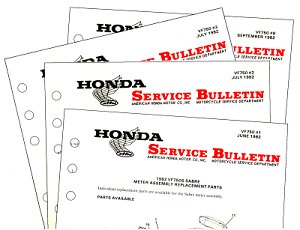

The almost-official checklist, sent by Western Union to all the dealers. This copy was retrieved from Long Beach Honda in Long Beach, California. Click to enlarge.

|

factory said to check on problem machines. This list included valve adjustment -- still being done with only one feeler gauge -- retorquing the rocker arm shafts, increasing the spark plug gap, checking for improper choke cable routing, straightening kinked Magna fuel pump hoses, and adjusting float levels on all models (they came over a very lean 9mm). No one seemed to know what was making the bikes run so poorly, and the company was reduced to grasping for the first few months. The special warranty contact team that I was a part of even sent out whole carburetor assemblies, and for really persistent customers, we authorized all sorts of unconventional service specs; many of them the EPA would have frowned on. But still the bikes clattered, wobbled, and got terrible fuel mileage. The fact is, easily 90 percent of the reports coming into the company involved poor driveability.

In June of 1982, a Western Union mailgram was sent to each U.S. dealer which put the official Honda stamp on the reps' 16-point checklist and added to it the now-classic tandem feeler gauge procedure. It also suggested the enrichment of the pilot circuits and checking the final drive cases for factory over-filling, two more areas of customer concern. By this time however Honda was already buying back bikes from angry owners. Despite this, the company was sold out of Sabres by the end of June, and Magnas would eventually sell well enough to make Detroit jealous; all in all a record-breaking year for Honda. Which was fortunate. It turned out also to be as expensive a warranty period as when Honda's first fours were introduced in 1969. It would be a while before the next company mega-party.

|

|

Two sheets of adhesive labels the dealer was sent to stick onto his customers' owner's manuals to revise the specs. Mostly it was about the final drive, including both oil level and the special alignment procedure. Click to emlarge.

|

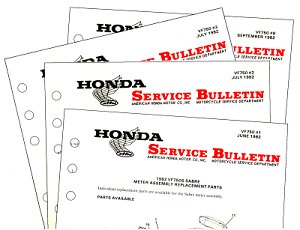

In July, the first handful of official bulletins formalizing the provisional recommendations were sent to dealers. These publications kicked off an EPA-approved factory program addressing most of the then-known problems. Along with instructions in proper valve adjustment, float level checks, etc., the dealers were sent stacks of adhesive corrections to be pasted over no fewer than five pages of each of their customer's owner's manuals. One such page detailed a new method of rear wheel installation that had been worked out only a few months previously on the GL1100. It was determined that the accelerated final driven flange wear evident in both the Wing and the V4 could be reduced by an unusual and painstaking alignment of the final drive unit each time the rear wheel was removed and replaced. The service manuals were revised as well, but unlike the Gold Wing, which received a generous warranty extension, the V4 situation went unpublicized and is largely unknown even today, though the special procedure is published in the two above-named factory-generated sources, and many shops are familiar with the problem. The July 1982 update program was a very big deal. Not only did it officially In July, the first handful of official bulletins formalizing the provisional recommendations were sent to dealers. These publications kicked off an EPA-approved factory program addressing most of the then-known problems. Along with instructions in proper valve adjustment, float level checks, etc., the dealers were sent stacks of adhesive corrections to be pasted over no fewer than five pages of each of their customer's owner's manuals. One such page detailed a new method of rear wheel installation that had been worked out only a few months previously on the GL1100. It was determined that the accelerated final driven flange wear evident in both the Wing and the V4 could be reduced by an unusual and painstaking alignment of the final drive unit each time the rear wheel was removed and replaced. The service manuals were revised as well, but unlike the Gold Wing, which received a generous warranty extension, the V4 situation went unpublicized and is largely unknown even today, though the special procedure is published in the two above-named factory-generated sources, and many shops are familiar with the problem. The July 1982 update program was a very big deal. Not only did it officially

|

|

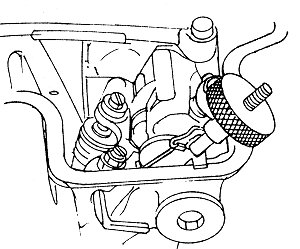

I removed this valve cover from a VF750S that was in for an oil leak. You think? The valve adjusting nut went through the cover with enough force to make that 2 1/2" hole. The cover is almost a quarter inch thick by the way. The wrench in the foreground is the factory tool that prevented this issue until the rocker arms were revised in 1985. Click for bulletin.

|

disseminate the techniques and data found to be essential for good-running V4s, it also formally mandated the use of 07908-MBO0100, the long 10mm valve adjusting screw locknut wrench, whose use was designed to prevent the locknuts from loosening and being rocketed through the 6mm thick valve covers. Normal tightening wasn't enough, it was ultimately found, because the rough, "as forged," unmachined surface on the rocker arm was not allowing proper tightening of the nut. The extra long wrench was the immediate fix, but by 1985, the rocker arms in the new bikes would be milled flat under the nuts, and the adjusting screw diameter increased. This increased tightening torque and security.

In August of 1982, a new department was formed dedicated to monitoring new model problems and communicating strategy for solutions to Japan. The group's first move was to ensure the availability of V4 oil filters and service manuals, which were -- five months after the bike's release -- still on backorder. Not even engine gaskets were available, a situation that resulted in Honda having to give away a number of engines. The team also called for an immediate field modification of the V4's float bowl vents. It came to light that a major cause of the engine's lean surge was the effect that inconsistent air pressure

|

|

The tapered plastic float bowl vent restrictor jets that dealers had to insert in early models and which came preinstalled later...and which were eventually removed again on certain models. Click for bulletin.

|

was having on the fuel levels (the vents are inside the airbox). Mere correction of lean levels wasn't enough; the levels were oscillating as the engine ran. This was another major stride in the V4's gentrification, and one for which credit goes to the field reps, who, having discovered the phenomenon, had, in typical field tech style, been quietly screwing CR250R air bleed correction jets into the airbox vent orifices of their dealer's problem units, with remarkable success. The new edict merely put a more sophisticated face on the situation by specifying specially-manufactured tapered plastic restrictive inserts, Honda code 1357490. In September, VF750 Bulletin #8 formalized the procedure, and a year later the V65 received the same treatment.

|

|

The 1982 cylinder head underneath, the 1983 on top, having additional cam bearing surface along with tighter clearances. I took this pix while changing out the heads at Honda's expense. Click for memo.

|

By October of 1982, the '83 dealer convention was history and with the new season underway, Honda engineers were informing us that many of the improvements made in the 1983 models would be available as replacement parts. With the year they had just experienced, the company had learned a lot about their new progeny, and one of the most important lessons concerned the cylinder head. The '83 heads got noise-abating reduced cam-to-bearing clearance, and the journal area under the cams was increased. Most of these head kits went to dealers in so-called "lemon law" states.

Midway into the '83 model year, which was graced with the introduction of the remarkable Interceptor, the dust began to clear at American Honda. The panic of '82 was over, and the motorcycle service division's new slogan, "Out in Front and Pulling Away," aptly represented the feeling of accomplishment within the company. Interceptors were winning races, and the public was no longer mad at Honda. Warranty activity was still high, but we were no longer getting up at  dawn to field phone calls two time zones away and two and a half weeks waiting. There were still problems, of course. Crooked sidecovers, recaltrant alarm systems, weaves and wobbles. Mufflers that spit out their baffles. Instruments with minds of their own. Frames cracking under the seat area (leading to a design change in 1985). Loose crankcase oil gallery plugs, incorrectly made seat locks. Oil lines that broke. Plus, there was still the occasional customer with a noisy engine whose dealer didn't understand the dual-feeler procedure, and we still sent out the occasional carb assembly, despite the special letter to dealers categorically discontinuing the practice (fully 90 percent of the carbs returned to us had merely been badly adjusted by the dealer). dawn to field phone calls two time zones away and two and a half weeks waiting. There were still problems, of course. Crooked sidecovers, recaltrant alarm systems, weaves and wobbles. Mufflers that spit out their baffles. Instruments with minds of their own. Frames cracking under the seat area (leading to a design change in 1985). Loose crankcase oil gallery plugs, incorrectly made seat locks. Oil lines that broke. Plus, there was still the occasional customer with a noisy engine whose dealer didn't understand the dual-feeler procedure, and we still sent out the occasional carb assembly, despite the special letter to dealers categorically discontinuing the practice (fully 90 percent of the carbs returned to us had merely been badly adjusted by the dealer).

|

|

A political deal, this. Absolutely no relation to reality. The factiry blamed their dealers. See the footnote below. Click for bulletin.

|

By early 1984, the cam problems surfaced, though it would be another year before Honda, pressured by the aggressive European motor press, would admit their existence. Motorrad in particular was fairly blunt about the matter. Its April 1984 feature article depicted a plastic model of a 750 Inteceptor being rubbed into a hand-held cheese grater, with parts -- most noticably a camshaft (although the cam is obviously from a CX500!) -- emerging on the other side. At the same time, Honda's European branches were issued the infamous special cam tool and related propaganda. April also brought fuel tank recalls on all of the California models. July gave us engine replacements on VF500F Interceptors, and August 1984 saw information come out concerning Hondaline fairing problems on the V65 Sabre. A kit was assembled to correct the fairings and a bulletin issued. The following month, dealers heard from Honda concerning the removal of foam strips from the forks of '83 and later V4s (Service Letter #11), and they were instructed to eliminate V4 wobble by a special steering bearing alignment procedure.

|

|

Honda scrambled for a solution to the cam problem. Several revisions in just the V45 cams included different heat treats (evident here) and oil passage holes in the cams also. But all to no avail. The problem was not the cams.

|

Finally, in June 1985, the controversial cam tool arrived at U.S. dealerships, accompanied by Service Letter #13 specifying a new adjustment procedure and revised idle rpm specs. At the same time, a three-year warranty extension and factory-paid replacement of scarred cams was announced, but only for the '83 and '84 Interceptor, the focus of the Euro press. Less than a month later, however, American Honda shot off to its dealers a parts memo offering the buyback of any and all V4 cams in dealer's stocks. Though this memo said nothing about warranty, the cat was now out of the bag. All told, there had been eight camshaft supersessions for just the '82 and '83 Sabre

|

|

This special, unadvertised kit contained cams and bearings (only the cams are shown here) hand-matched, to reduce the excessive cam ckearance that made 1982 V45 engines pretty clattery. The kit was great, but Honda techs achieved the same results by simply sanding down the bearings on a sheet of glass.

|

and Magna, a fact that was already clear from a careful perusal of the official parts book, but which became really significant when seen under Honda letterhead. Honda even addressed the '82 model's loose-as-a-goose cam bearings. A special 315 series cam kit was put together for these bikes which consisted of cams hand-matched to bearings. By 1986, the excitement was mostly over. The new generation of V4s closed the book on a period of Honda's history that the company presumably would just as soon forget. Honda's slogan for '86, "Consistently the Leader," spoke eloquently of the purifying fire of the previous four years and more than hinted at the company's renewed emphasis on quality.

Bulletins:

There would eventually be more than seventy official Honda notices concerning the early V4s.

Alignment:

Interestingly, Yamaha experienced the same problem at about the same time, on the Venture, and proposed a similar solution.

Restrictors:

Honda later admitted in a service bulletin that the restrictors were not always best. On some models they directed the technician to reverse the mod, thereby isolating the bowl vents from the airbox and eliminating the problem.

Lemon Laws:

Basically, the so-called "lemon law" (actually Breach of Warranty) says repairs required under warranty can't take over a certain number of days or the customer has a right to a full refund. In states without this law, the manufacturer had the option of repairing the vehicle over and over. Although all 50 states have lemon laws today, only a handful did in 1982.

Tool:

This tool is superfluous. It is also part of a big coverup. Just as the company blamed poor shifting 1981 CR250Rs on the public, when in fact the problem was badly-manufacturered transmissions, so they blamed worn camshafts on the dealer techs inability to correctly adjust the valves. Yes, the tool removes slop from the bearing, ostensibly making clearance adjustment more accurate. But the end product of using the tool is much tighter -- not merely more "accurate" -- valve clearances. When the tool is used, the engine's idle must be raised, in some cases quite high. It is typical for overtight valves to result in poor idling. Moreover, in August of 1985 and again in February of 1986, Honda themselves revealed its uncertainty regarding this "solution" to the cam problem, by suggesting in a dealer publication that the special tool wasn't in fact necessary to get correct valve adjustment (The Wrench newsletter, dates as indicated).

Fairing

There was another interesting situation regarding the Hondaline fairing for V65 Sabres. Testing by Honda Canada showed that the bike developed a weave, at post-legal speeds, if the Hondaline saddlebags were mounted in the absence of the fairing. At first, the decision was made to offer the bags only as part of the fairing package, in an effort to limit liability. Ultimately however this was deemed unfair (the fairing by itself retailed for almost $600 U.S.), and the saddlebags were dropped from the catalog.

Steering Bearings

Later models were built with ball-type bearings incorporating special plastic friction-adding roller cages, in an attempt to mitigate the overloaded tapered bearing's tendancy to "walk" in the frame and generate torsional forces in the fork assembly.

Postscript 2021: Dozens of years later, this article still speaks to the time. In light of all of the misinformation that has accumulated on the Internet in the interim, it may be even more timely.

|

®

®

Honda had just experienced a renewal of sorts. Thanks in part to Kawasaki's Z1, a lot of Honda's performance persona had faded, and apparently someone at the Big H didn't like that. The company made an effort to regain a sporting reputation, and with its reentry into world roadracing, the emergence of the NR500, NS750, CBX, and CX500 Turbo, as well as Freddie Spencer's success with the CB750F-based 1025cc production racers, there was more than advertising hype in Honda's new slogan, "Follow the Leader." Big Red was cooking once again.

Honda had just experienced a renewal of sorts. Thanks in part to Kawasaki's Z1, a lot of Honda's performance persona had faded, and apparently someone at the Big H didn't like that. The company made an effort to regain a sporting reputation, and with its reentry into world roadracing, the emergence of the NR500, NS750, CBX, and CX500 Turbo, as well as Freddie Spencer's success with the CB750F-based 1025cc production racers, there was more than advertising hype in Honda's new slogan, "Follow the Leader." Big Red was cooking once again.

The new V4 streetbikes were released against this heady backdrop of success, and they were impressive monuments to Honda's engineering prowess. The motopress gushed with enthusiasm. Honda threw private company parties at

The new V4 streetbikes were released against this heady backdrop of success, and they were impressive monuments to Honda's engineering prowess. The motopress gushed with enthusiasm. Honda threw private company parties at

In July, the first handful of official

In July, the first handful of official

dawn to field phone calls two time zones away and two and a half weeks waiting. There were still problems, of course. Crooked sidecovers, recaltrant alarm systems, weaves and wobbles. Mufflers that spit out their baffles. Instruments with minds of their own. Frames cracking under the seat area (leading to a design change in 1985). Loose crankcase oil gallery plugs, incorrectly made seat locks. Oil lines that broke. Plus, there was still the occasional customer with a noisy engine whose dealer didn't understand the dual-feeler procedure, and we still sent out the occasional carb assembly, despite the special letter to dealers categorically discontinuing the practice (fully 90 percent of the carbs returned to us had merely been badly adjusted by the dealer).

dawn to field phone calls two time zones away and two and a half weeks waiting. There were still problems, of course. Crooked sidecovers, recaltrant alarm systems, weaves and wobbles. Mufflers that spit out their baffles. Instruments with minds of their own. Frames cracking under the seat area (leading to a design change in 1985). Loose crankcase oil gallery plugs, incorrectly made seat locks. Oil lines that broke. Plus, there was still the occasional customer with a noisy engine whose dealer didn't understand the dual-feeler procedure, and we still sent out the occasional carb assembly, despite the special letter to dealers categorically discontinuing the practice (fully 90 percent of the carbs returned to us had merely been badly adjusted by the dealer).