|

|

|

Knowing these parts' names sets us up for the discussion to follow. The piston is actually a very complex part containing a lot of technology.

|

Which is better, the cast piston or the forged piston? This argument doesn't come up as often as it used to. During the 1970s it was a frequently debated topic, rather like engine oil or brake fluid. The answer used to be simple, because one type of piston was in fact better than the other. Today however, things are not so simple. Things have changed. A person can't be as dogmatic as they would like, and anyone who is insistent just doesn't know the facts. Here are those facts.

Piston Basics

The piston is under-appreciated, for sure. It may be the hardest-working part in the internal combustion engine. Following is just a brief outline of the piston's function and construction.

Three Jobs

The piston does three important jobs. It is a bearing, receiving loads from combustion and transferring them straight and true through the connecting rod to the crankshaft. The piston is also a seal, as it seals combustion's forces and compression's trapped air. Finally, the piston is a heat conductor, transferring some of the cylinder's heat to the outside. In fact, nearly 80 percent of the cylinder's excess heat is drawn away by just the piston's rings. Hmm.

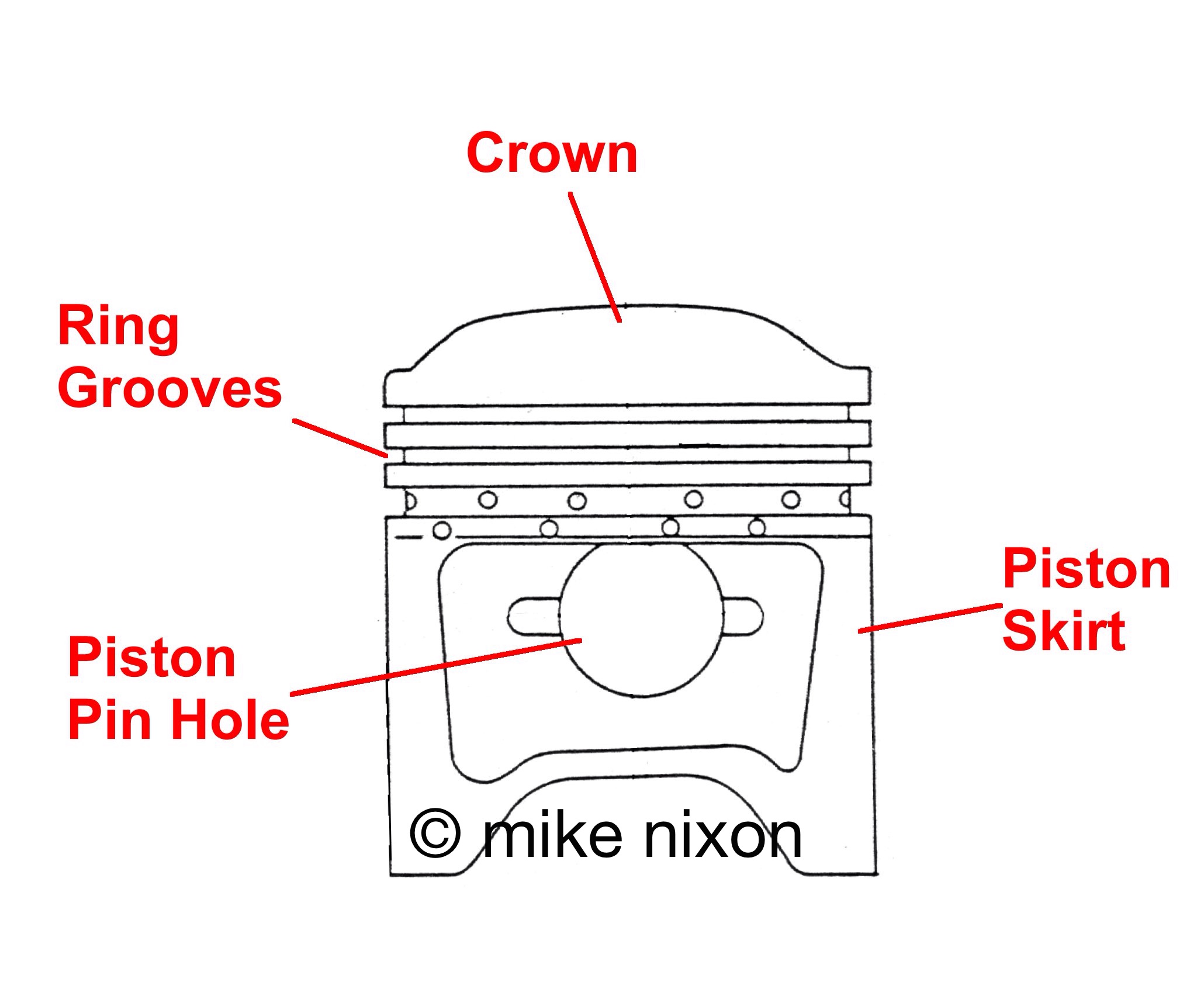

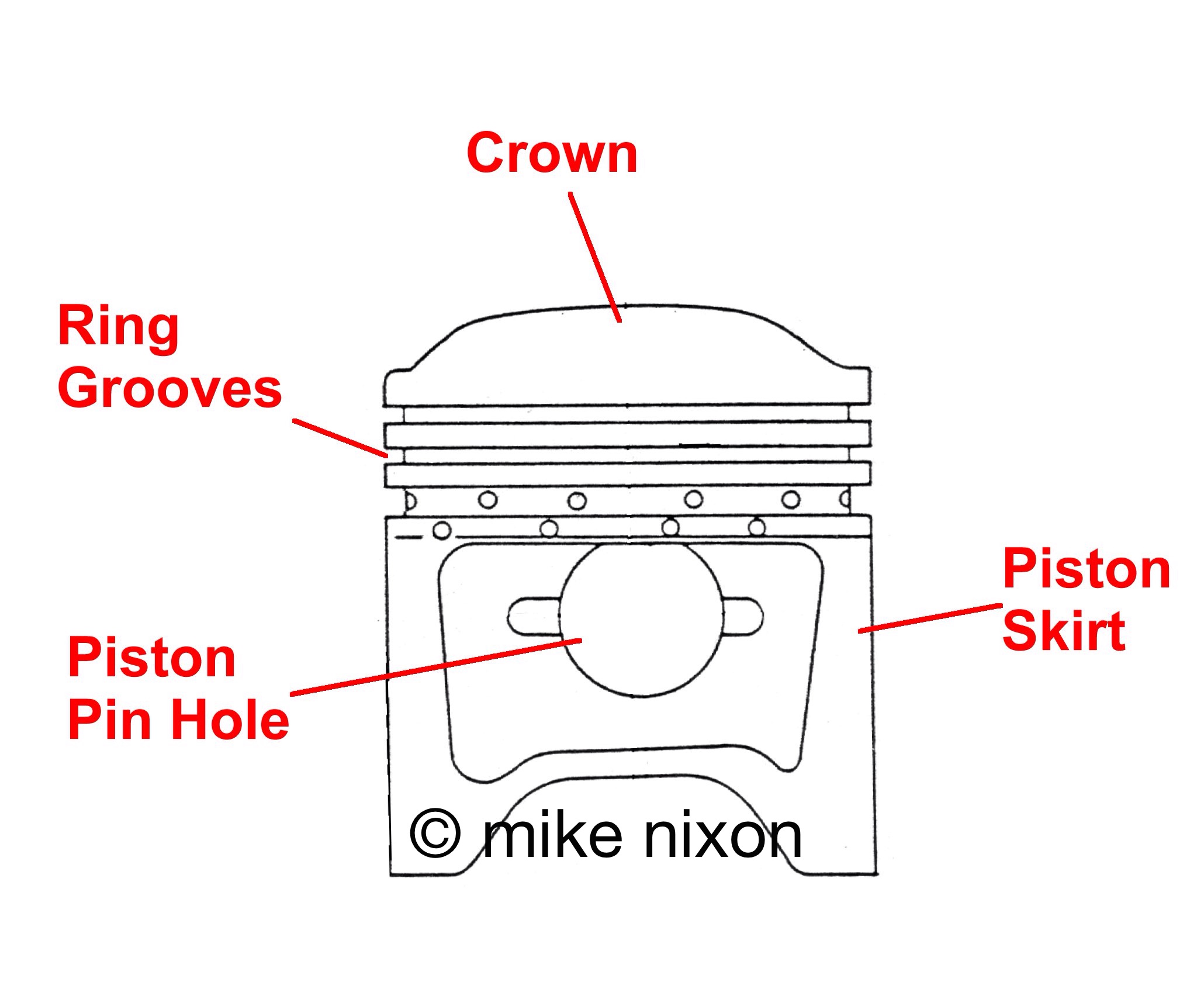

Piston Parts

The piston is made of essentially seven parts. The piston's top or crown takes the brunt of combustion's forces and heat. Consequently, the piston's crown is the hottest part of the engine. It must therefore be quite thick so as to not collapse or melt. Moving down the piston, the next thing is the ring groove. The closely manufactured groove accepts the third part, the precisely made piston ring. In the four-stroke engine, natural harmonics cause the ring to rotate as the piston goes up and down in the cylinder. This helps the groove stay clean of carbon and ensures uniform ring and cylinder sealing. The solid pieces between the grooves are called ring lands. They are similar to the lands in a gun barrel. They support the shock loads the rings receive during combustion. The next part is the piston pin hole. This hole accepts a pin that connects the piston to the connecting rod. In road-going engines and those designed for high rpm the hole is offset from the piston's center slightly so that when the piston and rod reach TDC, they do so at slightly different times. This spreads the shock loads, easing stresses on the connecting rod and eliminating a noise called "piston slap." Surrounding the hole inside the piston are pin bosses, thick masses of metal that support the pin when it is inserted in the hole. The pin bosses are typically the thickest part of the piston, and with the crown, the next thickest part, largely determine how the piston reacts to heat, particular the shape the piston will take when hot, as the piston expands the most in these thick areas. Lastly, we come to the piston skirt. The skirt is the bearing portion of the piston. It slides against the cylinder wall, bearing the force of combustion on the power stroke, and the loads of compression on the compression stroke. There are also stresses involved with rpm that the piston and cylinder are designed together to deal with. The skirt is the part of the piston most in need of lubrication. Thus most lubrication problems show up on the piston skirt first as scoring and other visible indications. Finally, with the skirt being the point of the piston's largest diameter, it is here that the critical fit of the piston in the cylinder is determined.

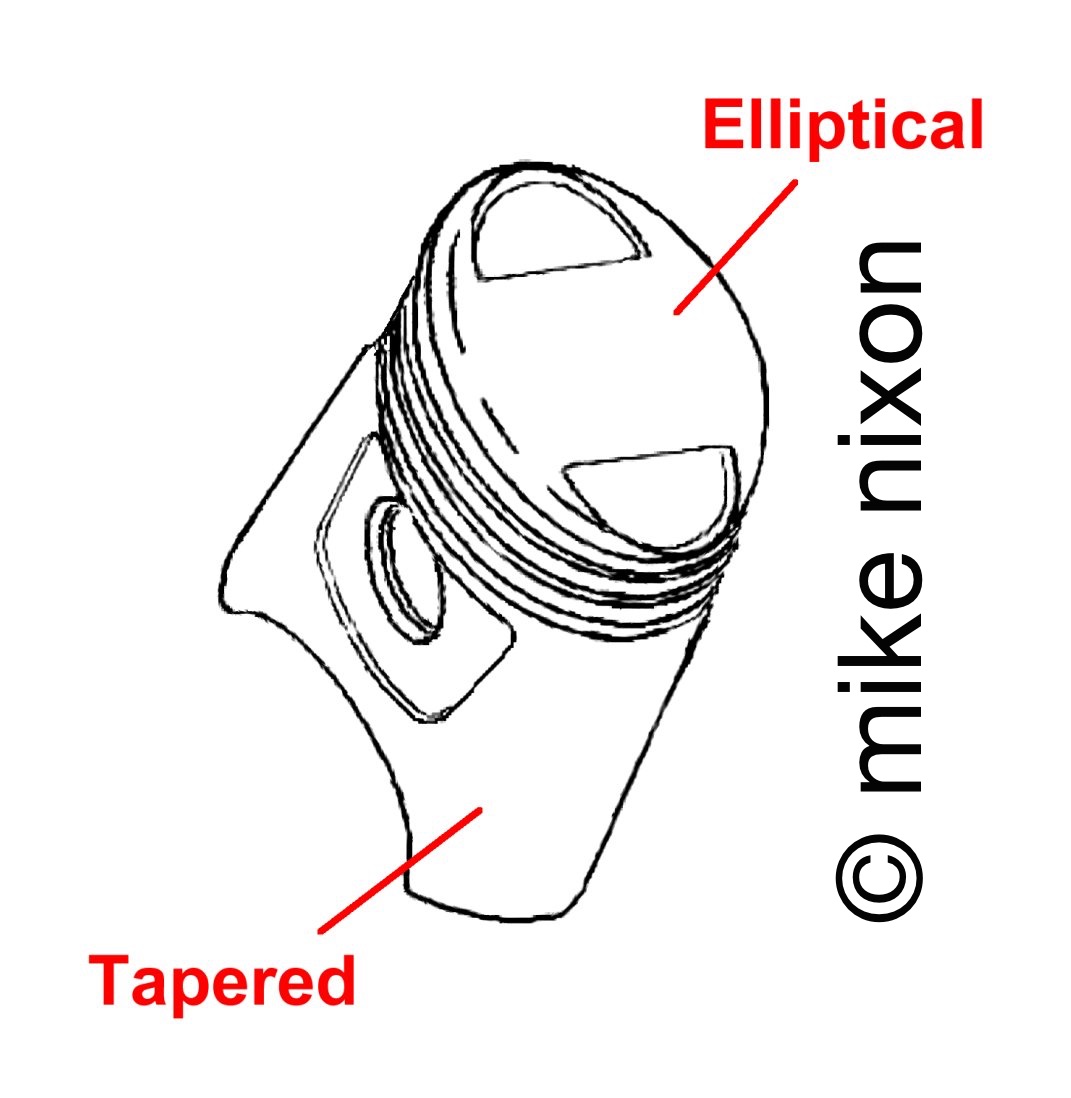

Piston Shapes

|

|

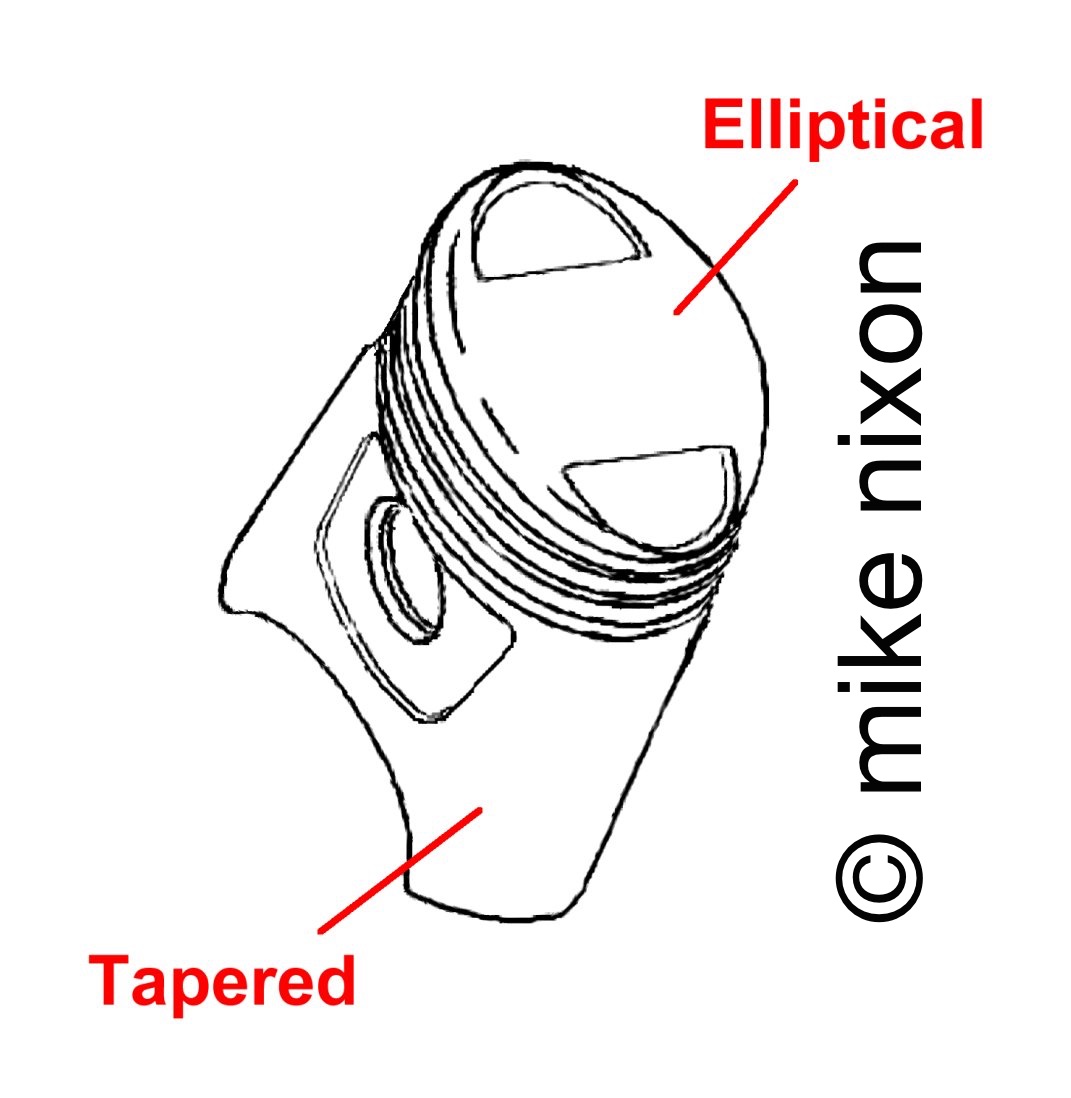

While the cylinder absolutely has to be round and straight, the piston must not be until it is fully heated up and has expanded and distorted. It is made elliptical and tapered to accomodate this expectation. The shapes on this drawing are exaggerated of course, but they're really there.

|

There are two important ways in which all modern pistons are shaped. First, the piston is not round, but elliptical in shape. The reason is the afore-meentioned pin bosses. The bosses' mass makes them absorb a lot of heat, which makes them expand more than any other part of the piston. If the piston was instead made round, because of the massive pin bosses it would not be when fully warmed up. That would be a problem. Therefore, the width of the piston at the area of the bosses is narrower than it is elsewhere. The resulting shape (looking downward onto the piston crown) is an ellipse (an oval). Marine pistons are sometimes called "cam ground," which refers to the same thing (however, it isn't the shape that is being referred to in that case, but rather the machine that produces it). The other (second) shape all pistons have is taper. That is, the diameter of the piston at its crown is considerably smaller than its diameter at the skirt. The reason is the same as for the piston's ellipse. Only this time it is the crown, not the pin bosses, that necessitates the shape. The crown, again due to its mass, its thickness, absorbs so much heat that it must be made smaller so that when fully heated, the piston will be straight.

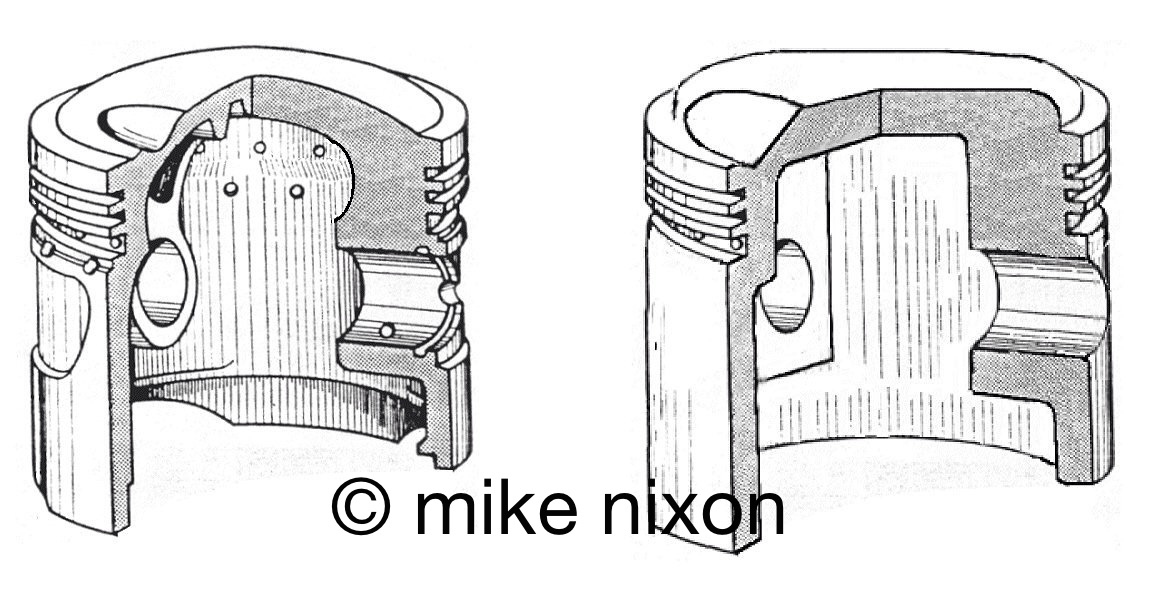

Piston Manufacturing Methods

Pistons are manufactured in one of two ways. Those two ways are the cast piston and the forged piston. This brings us back to our question, which is better, cast or forged? But not so quickly! The cast piston is made of molten aluminum. The alloy is flowed into a mold having the shape of the finished product, in much the same way that many other cast parts are made. However, don't imagine wooden boxes full of coarse sand, into which melted aluminun is poured. Piston molds are actually permanent dies, intricately made multiple-piece steel shapes. The molten aluminum is vacuum drawn into the mold. So accurate is the process that the resulting casting requires minimal machining. That's the cast piston. The forged piston is made very differently. The metal is not molten, but heated somewhat. A blob of this hot aluminun alloy (called an ingot) is placed in a female mold, and a male ram is pounded into it. The result is not a piston, but a piston blank, which must then undergo many machining operations before it resembles a piston. These two methods of making pistons continue today, and there are interesting and valid reasons for both of them. Let's examine those reasons by looking at the history and applications of each piston type.

The Cast Piston

The cast aluminum alloy piston has perhaps the longer history. It took over for the original steel part (yup, steel!) during the internal combustion engine's early development. The cast piston is the most familiar piston type, because it is used in the majority of street machines even today.

|

|

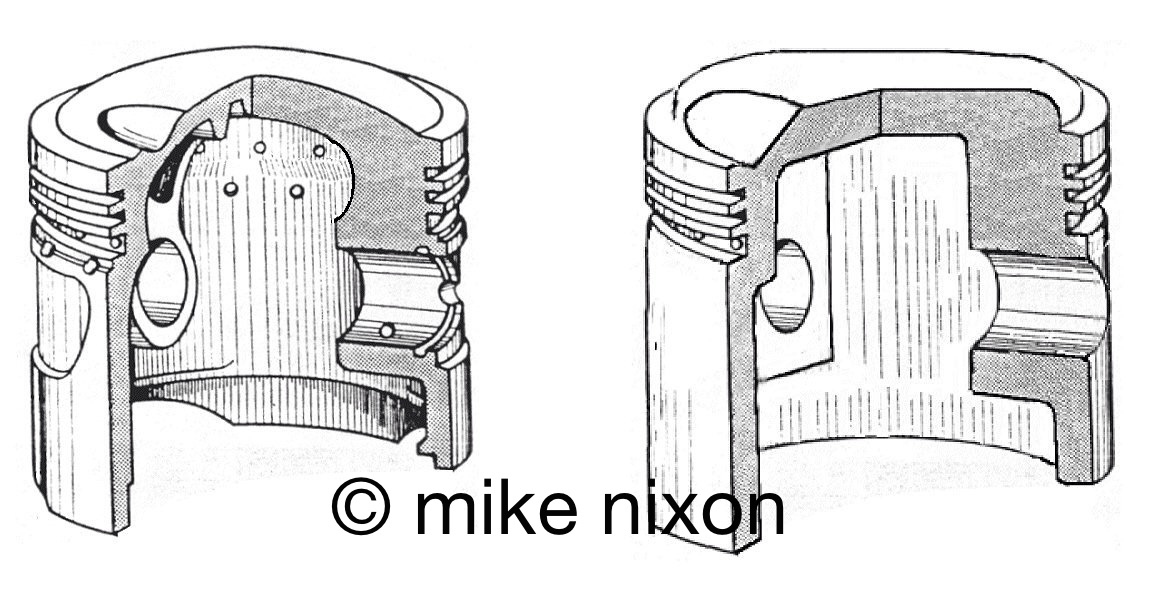

Pistons are generally made in only two ways, cast and forged, although there are a few completely CNC machined pistons out there as well, especially in today's specialty market. Note that it is very easy to distinguish the two, by looking for material above the pin boss. If there is mass there, and more specifically, in the straight-sided shape of the forging ram, the piston is forged. If not, and there are no tool marks to indicate it was removed after manufacture, then the piston is cast.

|

Casting Alloys

Harley-Davidson and Triumph pistons originally had steel ribs inside them to control this expansion, because the earliest cast aluminum pistons were made with inferior alloys. The piston expanded dramatically, requiring a loose fit in the cylinder and resulting in noisy operation when cold. Since then however piston alloys have gained silicon, a material that gives the pistons natural lubricity and limits heat expansion. All modern pistons have silicon in them. However, cast pistons have historically had the most. Some of them have as much as 25 percent silicon by volume. Silicon does bring a disadvantage however. It makes the piston brittle. Dropping a modern cast piston will usually crack it, so the piston must be handled carefully.

Mass Efficiency, Part One

Probably the greatest benefit of the cast piston is the efficiency of its mass. The multiple-piece molds allow intricate contours inside and out, resulting in light weight, good expansion control, and predictable heat flow through the part. That is, the piston designer can plan in the specific thickness in each place in the part that is desired, to result in expansion at those places that is warranted. Expansion is controlled so well that OEM users of the cast piston have historically fitted this piston in many cases with less than a thousandth of an inch clearance! So predictable is the cast piston's heat scenario in fact that race tuners view the undersides of the piston to gauge the combustion efficiency of the engine. In much the same way others read spark plugs, they read the dark splotches under the cast piston's crown.

Applications

The cast piston is however extremely expensive to manufacture. Die casting is costly, because it requires huge machines that do very specific jobs, and can't be easily adapted to do more than one kind of job. The result is that the casting process for pistons is relegated to the large piston supplier. The downside is that the cast piston is often found only in OEM specified sizes and types. There aren't a lot of different cast pistons to chose from if you are modifying an engine. The upside of this situation is that since only large piston manufacturers can afford to make cast pistons, they are usually very competently made. In fact, the cast piston generally typifies the best technology that the piston industry has to offer. However, this doesn't mean it's the best piston for every application, as we'll see in a moment.

The Forged Piston

The forged piston is a more recent development. It appeared first on early, cantankerous two-stroke engines that were prone to frequent overheating and detonation. Both of these traits, as we'll see, made the forged piston a pretty good match for this application.

|

|

Note how thin the top ring is on this piston. The latest pistons have ultra-thin rings, under 1mm (0.040") and many are as thin as 0.5 millimeter, which feels kinda spooky to your hands when you're working with them, installing them. They feel almost knife-edged!

|

Forging Alloys

As with the cast piston, the earliest forged pistons were made with poor alloys. The same silicon-induced brittleness that makes the cast piston crack when dropped would have resulted in defects during the forging process had it been used in a forging. Consequently, during the time that the cast piston defined a piston's normal expansion rate, the forged piston was far behind the technology, and this famous for excessive expansion. The forged piston had to be fitted loose, which made it noisy and wasted power. Recently however, silicon has been introduced to the forged piston. A mixture of alloys has been found that together with silicon do not result in defective forgings. For example, nickel has been found to offset the silicon's tendency toward brittleness. However, not very much nickel can be used, as it is a heavy metal, and it affects the mixture in other ways. The result is that the modern forged piston is much more dimensionally stable than was true in the past. It's a much better product, comparable in every way to the traditional cast piston.

Mass Efficiency, Part Two

However, once again, mass is critical. The fact is, the forged piston's mass does more to define its characteristics than does even its materials. The forged piston has historically had a crude interior shape. The forging ram is straight, which results in a rectangular interior rather than the cast piston's intricate interior. There is a lot of mass there. Consequently, the forged piston has less ideal dimensional stability than does the cast piston. Its expansion is not very controllable. Many engine builders overcome these two problems (too much weight, unpredictable expansion) at least partly by removing by hand the extra material inside the forged piston. This allows them to fit them tighter and rev them higher. However, many forged pistons also have overly thick skirts as well as unsophisticated interiors. This is because the forging produces a piston blank, remember, and not a finished piston. The piston wholesaler takes this blank, and from it, through many machining steps carves out several different sizes and shapes of pistons. If the piston being made happens to be the largest the blank supports, it ends up with the thickest skirt. While hand reworking (or CNC milling, as many do now) the forged piston can lighten it and make it behave more like an intricately made cast piston, there is still excess weight due to the thick skirt.

|

|

An Axtel 97mm Harley Evo piston made by JE. Note the massive pin boss area, and the very thick crown enabling much modification, as shown here. Note also the modern, ultra-thin top ring grooves. Bonus points if you can spot why this piston was sacrificed for the photo...

|

Applications

One of the forged piston's advantages is that unlike the cast piston, the forged piston is easy to manufacture. Smaller piston manufacturers therefore specialize in this piston type, even if some of them may not be as competent at making pistons as are the larger cast piston makers. Forged pistons have quickly become the choice of custom engine builders because they can be had very quickly, and in virtually any configuration desired -- even custom ordered. Moreover, and a huge bonus, the forged piston's added thickness, particularly in the crown, is used by these builders to custom configure the piston even further. For example, flycuts on the piston's crown for high performance valve relief is an easy process with the forged piston. There's a lot of material there in which to do it, much more than there is in the cast piston. The forged piston was also the first piston type to adopt the modern ultra-thin piston ring, for the same reason. It could be done easily and immediately. There were no molds for such a piston among the cast piston manufacturers for years after thin (1mm and under) rings appeared on forged pistons. This situation has resulted in the forged piston acquiring something of a high performance personna, even though in metallurgy it is considered by many to be less current than that of the cast piston. The forged piston is inherently stronger than the cast piston. Lower silicon content of course would result in this, making the forged piston less brittle. However, there is another reason as well. The forging process somewhat aligns the metal molecularly, giving the piston a slight edge in toughness, over the cast piston. The result is a piston that withstands the pounding of detonation particularly well. This is why OEMs tend to break tradition and use the forged piston in two-strokes, supercharged engines, and other specialty, high output engines. Forged pistons are also included in many OEM high performance options kits for their street models.

Conclusion

To sum up, the cast piston is light and very dimensionally stable, thus able to be fitted tightly. It is found in high-rpm mass-produced engines that are not subject to modification or otherwise prone to excess heat or damaging detonation. The cast piston is however fairly brittle and thus delicate, and the cost of its manufacture has limited its availablity outside the OEM sources and applications. On the other hand, the forged piston is inherently heavy and less dimensionally stable. But its superior strength makes it a good choice for engines in which detonation is probable, and its wide availability (due to less expensive manufacture) and ability to be customized has made it the de-facto choice of engine modifiers. The special demands of the forged piston's special end users has given it its own unique niche in the powersports market. Both piston types are legitimate, neither is superior to the other, each has its special application and unique role in powerports engines.

|

®

®