Here's an oft-repeated motorsports fallacy: "Multiple-valve engines are designed to run very high rpm." Everybody knows this to be true. Unfortunately, everybody is wrong. The fact is, the multi-valve engine does not run appreciably more rpm than the two-valve engine. Rpm is not the thing. There are more important reasons for the multi-valve engine, reasons that go way beyond rpm.

Rpm-Related Benefits

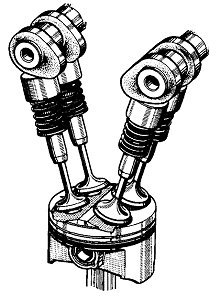

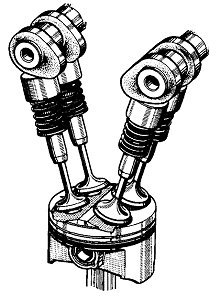

That's not to say that the multi-valve head doesn't like high rpm. It does. Here are three rpm-related bendfits of the multi-valve cylinder head. All are related to the valve's reduced mass. First, smaller valves have less inertia. This means they are easier to control at higher rpm, so higher rpm is possible. There is less tendancy for the valves to "float," that is, loft off the cam lobe slightly, which is one of the many barriers to high rpm in an engine.  Second, smaller valves require less spring pressure. Many multi-valve engines have just one spring per valve instead of the traditional two. Without the second spring, spring harmonics problems associated with high rpm are eliminated, removing yet another obstacle to high rpm. And third, a bunch of smaller valves use up the combustion chamber's ceiling more completely than can fewer, larger valves. The result is more efficient use of the chamber's potential flow area. The scattering of little valves all over the combustion chamber's ceiling are essentially one big valve in effect. Therefore high flow is possible, and if the rest of the engine can support that flow (that is, mechanically keep up, and burn it and exhaust it), then high rpm is possible.

Second, smaller valves require less spring pressure. Many multi-valve engines have just one spring per valve instead of the traditional two. Without the second spring, spring harmonics problems associated with high rpm are eliminated, removing yet another obstacle to high rpm. And third, a bunch of smaller valves use up the combustion chamber's ceiling more completely than can fewer, larger valves. The result is more efficient use of the chamber's potential flow area. The scattering of little valves all over the combustion chamber's ceiling are essentially one big valve in effect. Therefore high flow is possible, and if the rest of the engine can support that flow (that is, mechanically keep up, and burn it and exhaust it), then high rpm is possible.

Not All Are High-Rpm Engines

All of these things would seem to equate the multi-valve head with high rpm. Despite this, high rpm is not the reason for the multi-valve head. If it were, all multi-valve engines would be high-rpm engines, and they are not. Multi-valve cylinder heads are found in touring bikes, offroad machines, personal watercraft, and even on Harley-Davidsons (aftermaket for earlier models, OEM on the V-Rod), as well as any number of cars. Where's the high rpm in these vehicles? The truth, the benefits of the multi-valve head are much more involved than simple rpm. As complex as the real benefits are, they can be reduced to just one thing -- combustion.

Three Benefits Relating to Combustion

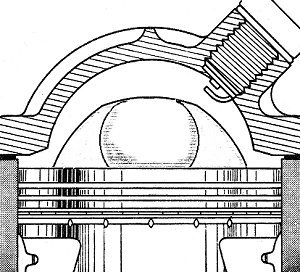

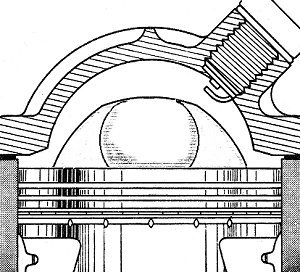

The multi-valve cylinder head is all about combustion. This is logical. That is what the cylinder head itself is mostly about, and it is certainly what the combustion chamber is about, and the combustion chamber is where the valves are. There are three benefits of the multi-valve cylinder head that relate to combustion. We'll look at them in order of their complexity, that is, the simplest first. First, the multi-valve head is, most of all, an attempt at the ideal combustion chamber shape. Years ago, it was believed that the hemispherical combustion chamber was the best shape. From a purely geometrical standpoint, it is. The hemi's constant radius theoretically encourages a very uniform rate of travel for combustion's flame, resulting in more predictable consumption of the air/fuel charge. The problem is, a hemi shape results in a very large chamber, one too large for adequate compression without using high-domed pistons. Those pistons mess up the chamber's uniform shape, trapping end-gases far from combustion's flame, encouraging detonation. In short, the hemi has good flame travel until you stick a piston in it -- then it's terrible. Furthermore, the sheer volume of the hemi chamber requires so much ignition advance to get the job done that too much time is spent heating up the engine and not enough in making power.

The multi-valve cylinder head is all about combustion. This is logical. That is what the cylinder head itself is mostly about, and it is certainly what the combustion chamber is about, and the combustion chamber is where the valves are. There are three benefits of the multi-valve cylinder head that relate to combustion. We'll look at them in order of their complexity, that is, the simplest first. First, the multi-valve head is, most of all, an attempt at the ideal combustion chamber shape. Years ago, it was believed that the hemispherical combustion chamber was the best shape. From a purely geometrical standpoint, it is. The hemi's constant radius theoretically encourages a very uniform rate of travel for combustion's flame, resulting in more predictable consumption of the air/fuel charge. The problem is, a hemi shape results in a very large chamber, one too large for adequate compression without using high-domed pistons. Those pistons mess up the chamber's uniform shape, trapping end-gases far from combustion's flame, encouraging detonation. In short, the hemi has good flame travel until you stick a piston in it -- then it's terrible. Furthermore, the sheer volume of the hemi chamber requires so much ignition advance to get the job done that too much time is spent heating up the engine and not enough in making power.

Current combustion chamber technology dictates very flat combustion chambers. As it happens, the multi-valve chamber is a natural for this flat shape: many smaller valves permit a flatter chanber shape than do fewer larger ones. Moreover, the reduced volume of this chamber results in a shorter flame period, which means ignition timing doesn't have to be advanced as far. This is why modern engines run so much less ignition timing than older ones do. The result is free power because for whatever number of crankshaft degrees that are saved, the engine is no longer fighting itself, with the piston compressing an already-burning mixture. Remember also that the piston is part of the combustion chamber. With their flat-topped pistons, high compression is possible in these chambers without detonation. There are no nooks and crannies in which end-gases can hide. This chamber's flatter pistons also presnt to the chamber less surface area and therefore absorb less of combustion's heat. Even though the modern engine has much more compression that the engines of old, their temperatures are not correspondingly higher and detonation is far less common. More of combustion's heat is put to the useful work of pushing on the piston. Hence, more power.

Current combustion chamber technology dictates very flat combustion chambers. As it happens, the multi-valve chamber is a natural for this flat shape: many smaller valves permit a flatter chanber shape than do fewer larger ones. Moreover, the reduced volume of this chamber results in a shorter flame period, which means ignition timing doesn't have to be advanced as far. This is why modern engines run so much less ignition timing than older ones do. The result is free power because for whatever number of crankshaft degrees that are saved, the engine is no longer fighting itself, with the piston compressing an already-burning mixture. Remember also that the piston is part of the combustion chamber. With their flat-topped pistons, high compression is possible in these chambers without detonation. There are no nooks and crannies in which end-gases can hide. This chamber's flatter pistons also presnt to the chamber less surface area and therefore absorb less of combustion's heat. Even though the modern engine has much more compression that the engines of old, their temperatures are not correspondingly higher and detonation is far less common. More of combustion's heat is put to the useful work of pushing on the piston. Hence, more power.

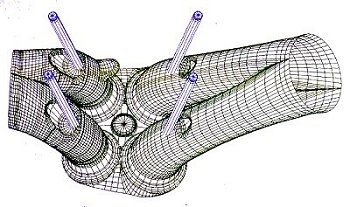

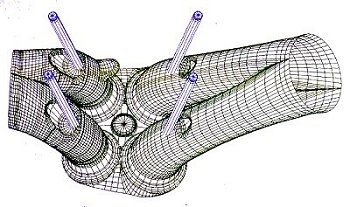

The second combustion-related benefit of the multi-valve combustion chamber centers on the valves. With two or three intake valves opening at the same time instead of just one, more port area is exposed at a given valve lift.  That is, the port is opened to a given amount in fewer crankshaft degrees than is possible with just one intake valve. There is more instantaneous port opening. The effect of this is interesting. The air/fuel mixture waiting in the port has a more immediate urgency to enter the cylinder when the intake port opens. The pull on it is more sudden. The result is increased cylinder filling, which results in higher combustion pressure and torque. On the road, this means improved low-rpm power and enhanced throttle response.

That is, the port is opened to a given amount in fewer crankshaft degrees than is possible with just one intake valve. There is more instantaneous port opening. The effect of this is interesting. The air/fuel mixture waiting in the port has a more immediate urgency to enter the cylinder when the intake port opens. The pull on it is more sudden. The result is increased cylinder filling, which results in higher combustion pressure and torque. On the road, this means improved low-rpm power and enhanced throttle response.

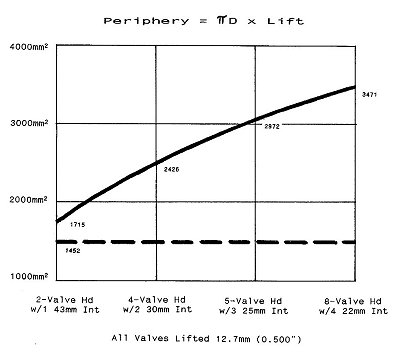

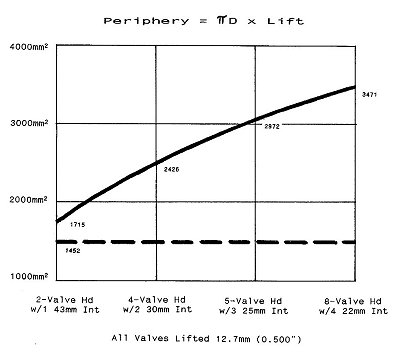

The third combustion-related benefit of the multi-valve chamber focuses on the ports. More specifically, the benefit is port velocity, that is, airspeed. The multi-valve head has higher intake port velocity than the two-valve head. This is perhaps the most significant benefit of all. The typical multi-valve design has small divided ports between the valves and the intake system. These smaller ports increase the average port velocity, which makes the air/fuel mixture enter the cylinder more homogenous -- better mixed. The result is better combustion, which translates directly to increased power, especially at low rpm. But that's just the beginning. Port velocity is also increased in the multi-valve engine by the effect of the valve's combined peripheral area. As the illustration shows, for a given intake valve area, peripheral area increases with the number of valves. Even with identical total valve area, two intakes have more peripheral area and therefore flow more than does one intake. Three intakes have even more, and so on. However, note

The third combustion-related benefit of the multi-valve chamber focuses on the ports. More specifically, the benefit is port velocity, that is, airspeed. The multi-valve head has higher intake port velocity than the two-valve head. This is perhaps the most significant benefit of all. The typical multi-valve design has small divided ports between the valves and the intake system. These smaller ports increase the average port velocity, which makes the air/fuel mixture enter the cylinder more homogenous -- better mixed. The result is better combustion, which translates directly to increased power, especially at low rpm. But that's just the beginning. Port velocity is also increased in the multi-valve engine by the effect of the valve's combined peripheral area. As the illustration shows, for a given intake valve area, peripheral area increases with the number of valves. Even with identical total valve area, two intakes have more peripheral area and therefore flow more than does one intake. Three intakes have even more, and so on. However, note ![]() that the actual valve area (the dotted line) hasn't changed. Therefore, velocity increases. That is, more flow with the same area results in more velocity. The result is, again, increased combustion efficiency. So multi-valve heads burn better, and the more intake valves there are, the better they burn.

that the actual valve area (the dotted line) hasn't changed. Therefore, velocity increases. That is, more flow with the same area results in more velocity. The result is, again, increased combustion efficiency. So multi-valve heads burn better, and the more intake valves there are, the better they burn.

The multi-valve cylinder head therefore offers many more benefits having to do with combustion than with rpm. Okay, but if multiple intakes are such a good thing, then why don't some engines have six, seven, or even eight valves per cylinder? In fact, they do. Maseratti produces six-valve chambers, and Honda's stupendous NR750 is an eight-valver. Yamaha's 5-valve Genesis design is of course the most famous. The company has gone on record as saying they experiemented with more than five but settled on that number as offering the most return for the investment -- the most bang for the buck. The reason is, as the chart shows, although the phenomenon continues to increase with the number of valves, it isn't as dramatic at eight valves per. The benefit begins to level off after five valves. The practical choice for Yamaha was to focus on that number. Make mine well-done, please...

®

®

Second, smaller valves require less spring pressure. Many multi-valve engines have just one spring per valve instead of the traditional two. Without the second spring, spring harmonics problems associated with high rpm are eliminated, removing yet another obstacle to high rpm. And third, a bunch of smaller valves use up the combustion chamber's ceiling more completely than can fewer, larger valves. The result is more efficient use of the chamber's potential flow area. The scattering of little valves all over the combustion chamber's ceiling are essentially one big valve in effect. Therefore high flow is possible, and if the rest of the engine can support that flow (that is, mechanically keep up, and burn it and exhaust it), then high rpm is possible.

Second, smaller valves require less spring pressure. Many multi-valve engines have just one spring per valve instead of the traditional two. Without the second spring, spring harmonics problems associated with high rpm are eliminated, removing yet another obstacle to high rpm. And third, a bunch of smaller valves use up the combustion chamber's ceiling more completely than can fewer, larger valves. The result is more efficient use of the chamber's potential flow area. The scattering of little valves all over the combustion chamber's ceiling are essentially one big valve in effect. Therefore high flow is possible, and if the rest of the engine can support that flow (that is, mechanically keep up, and burn it and exhaust it), then high rpm is possible.

The multi-valve cylinder head is all about combustion. This is logical. That is what the cylinder head itself is mostly about, and it is certainly what the combustion chamber is about, and the combustion chamber is where the valves are. There are three benefits of the multi-valve cylinder head that relate to combustion. We'll look at them in order of their complexity, that is, the simplest first. First, the multi-valve head is, most of all, an attempt at the ideal combustion chamber shape. Years ago, it was believed that the hemispherical combustion chamber was the best shape. From a purely geometrical standpoint, it is. The hemi's constant radius theoretically encourages a very uniform rate of travel for combustion's flame, resulting in more predictable consumption of the air/fuel charge. The problem is, a hemi shape results in a very large chamber, one too large for adequate compression without using high-domed pistons. Those pistons mess up the chamber's uniform shape, trapping end-gases far from combustion's flame, encouraging detonation. In short, the hemi has good flame travel until you stick a piston in it -- then it's terrible. Furthermore, the sheer volume of the hemi chamber requires so much ignition advance to get the job done that too much time is spent heating up the engine and not enough in making power.

The multi-valve cylinder head is all about combustion. This is logical. That is what the cylinder head itself is mostly about, and it is certainly what the combustion chamber is about, and the combustion chamber is where the valves are. There are three benefits of the multi-valve cylinder head that relate to combustion. We'll look at them in order of their complexity, that is, the simplest first. First, the multi-valve head is, most of all, an attempt at the ideal combustion chamber shape. Years ago, it was believed that the hemispherical combustion chamber was the best shape. From a purely geometrical standpoint, it is. The hemi's constant radius theoretically encourages a very uniform rate of travel for combustion's flame, resulting in more predictable consumption of the air/fuel charge. The problem is, a hemi shape results in a very large chamber, one too large for adequate compression without using high-domed pistons. Those pistons mess up the chamber's uniform shape, trapping end-gases far from combustion's flame, encouraging detonation. In short, the hemi has good flame travel until you stick a piston in it -- then it's terrible. Furthermore, the sheer volume of the hemi chamber requires so much ignition advance to get the job done that too much time is spent heating up the engine and not enough in making power.

Current combustion chamber technology dictates very flat combustion chambers. As it happens, the multi-valve chamber is a natural for this flat shape: many smaller valves permit a flatter chanber shape than do fewer larger ones. Moreover, the reduced volume of this chamber results in a shorter flame period, which means ignition timing doesn't have to be advanced as far. This is why modern engines run so much less ignition timing than older ones do. The result is free power because for whatever number of crankshaft degrees that are saved, the engine is no longer fighting itself, with the piston compressing an already-burning mixture. Remember also that the piston is part of the combustion chamber. With their flat-topped pistons, high compression is possible in these chambers without detonation. There are no nooks and crannies in which end-gases can hide. This chamber's flatter pistons also presnt to the chamber less surface area and therefore absorb less of combustion's heat. Even though the modern engine has much more compression that the engines of old, their temperatures are not correspondingly higher and detonation is far less common. More of combustion's heat is put to the useful work of pushing on the piston. Hence, more power.

Current combustion chamber technology dictates very flat combustion chambers. As it happens, the multi-valve chamber is a natural for this flat shape: many smaller valves permit a flatter chanber shape than do fewer larger ones. Moreover, the reduced volume of this chamber results in a shorter flame period, which means ignition timing doesn't have to be advanced as far. This is why modern engines run so much less ignition timing than older ones do. The result is free power because for whatever number of crankshaft degrees that are saved, the engine is no longer fighting itself, with the piston compressing an already-burning mixture. Remember also that the piston is part of the combustion chamber. With their flat-topped pistons, high compression is possible in these chambers without detonation. There are no nooks and crannies in which end-gases can hide. This chamber's flatter pistons also presnt to the chamber less surface area and therefore absorb less of combustion's heat. Even though the modern engine has much more compression that the engines of old, their temperatures are not correspondingly higher and detonation is far less common. More of combustion's heat is put to the useful work of pushing on the piston. Hence, more power.

That is, the port is opened to a given amount in fewer crankshaft degrees than is possible with just one intake valve. There is more instantaneous port opening. The effect of this is interesting. The air/fuel mixture waiting in the port has a more immediate urgency to enter the cylinder when the intake port opens. The pull on it is more sudden. The result is increased cylinder filling, which results in higher combustion pressure and torque. On the road, this means improved low-rpm power and enhanced throttle response.

That is, the port is opened to a given amount in fewer crankshaft degrees than is possible with just one intake valve. There is more instantaneous port opening. The effect of this is interesting. The air/fuel mixture waiting in the port has a more immediate urgency to enter the cylinder when the intake port opens. The pull on it is more sudden. The result is increased cylinder filling, which results in higher combustion pressure and torque. On the road, this means improved low-rpm power and enhanced throttle response.

The third combustion-related benefit of the multi-valve chamber focuses on the ports. More specifically, the benefit is port velocity, that is, airspeed. The multi-valve head has higher intake port velocity than the two-valve head. This is perhaps the most significant benefit of all. The typical multi-valve design has small divided ports between the valves and the intake system. These smaller ports increase the average port velocity, which makes the air/fuel mixture enter the cylinder more homogenous -- better mixed. The result is better combustion, which translates directly to increased power, especially at low rpm. But that's just the beginning. Port velocity is also increased in the multi-valve engine by the effect of the valve's combined peripheral area. As the illustration shows, for a given intake valve area, peripheral area increases with the number of valves. Even with identical total valve area, two intakes have more peripheral area and therefore flow more than does one intake. Three intakes have even more, and so on. However, note

The third combustion-related benefit of the multi-valve chamber focuses on the ports. More specifically, the benefit is port velocity, that is, airspeed. The multi-valve head has higher intake port velocity than the two-valve head. This is perhaps the most significant benefit of all. The typical multi-valve design has small divided ports between the valves and the intake system. These smaller ports increase the average port velocity, which makes the air/fuel mixture enter the cylinder more homogenous -- better mixed. The result is better combustion, which translates directly to increased power, especially at low rpm. But that's just the beginning. Port velocity is also increased in the multi-valve engine by the effect of the valve's combined peripheral area. As the illustration shows, for a given intake valve area, peripheral area increases with the number of valves. Even with identical total valve area, two intakes have more peripheral area and therefore flow more than does one intake. Three intakes have even more, and so on. However, note