|

Very few dealers are doing valve jobs any more. Not only has the cost of OEM replacement valves been high, but when added to the labor cost, the job takes on price proportions that effectively knock the average repair shop out of the game. When you can pick up a low mileage cylinder head complete with as-manufactured decent valves and seats from a salvage yard for a fraction of the repair order estimate... Today only speciality shops do cylinder head work and the nation's largest tech school has stopped training the skill. The valve job has become a lost art.

What is a valve job?

Cylinder head work is something many riders tackle themselves. However, done correctly, a valve job involves a lot of uncommon knowledge and expertise, and not a few specialized tools of a sort not likely to be found in the average person's garage. It is not simply yanking valves out, putting abrasive paste on them and burnishing the valves into their seats.

In fact, is not a part of anything professional technicians do. Also, the industry pro either does not use the ubiquitous Neway valve seat cutters at all or uses them only during the initial reconditioning stages on unusually heavily worn valve seats.

Valve lapping

Valve lapping is bad practice. It may have originated in connection with interference valve angles. Interference valve angles means the valve faces were, say, at 46 degrees and the seats at 45. The thinking was the difference ensured instant valve sealing by creating a knife-like edge on the valve seat. The fact is, this was a very tenuous geometry. Harley-Davidson, one of the practitioners of inteference angles, warned in early Sportster manuals about the loss of valve clearance merely miles after "valve jobs" are done in this fashion. This knife edge is not a good way to do things. Lapoing broadened the interference angle's knife-edge contact point. It rounded it off. Strangely, lapping has remained the final step in a few manufacturers' recommended technique long after interference angles have disappeared from powersports, mainly through inertia. Manufacturers see little reason to abandon it, especially since it "covers a multitude" of cylinder head reconditioning sins at the dealer level. Best practice it is not. Best practice is to recondition the seats perfectly, and then not having to rely on any artificial "wearing in," by lapping or whatever. This also means using good valve seat cutting methods in the first place.

Neway cutters

I had been trained on, had used extensively, and had significantly invested in, Neway cutters before I realized what they were. There are a number of problems with them. The first and foremost is that Neway is a "dead pilot" system. Dead pilot means the critical indexing point of the whole job is fixed, stationary. Worse, it's a tapered pilot pressed into the valve guide, and it is this pilot that the cutter revolves around. The dead pilot's taper practically ensures eccentricity because it will not center exactly in the in-service guide, meaning the cutter will cut the seat off-center. The best valve seat reconditioning systems, whether hand or powered, are "live pilot" type wherein the indexing pilot is one with the cutter and rotates with it. There is no taper involved, and guide wear is less an issue because the pilot is no more influenced by the guide's wear than is the valve. That is, it "floats" as does the valve. It finds its own center.

Another big problem with Neway cutters is they cut very aggressively, half a thou (0.0005") with each revolution, or more. They have to be used carefully or they can trash a cylinder head in no time. More importantly, no matter how carefully used, that is, even in the hands of a pro, Neway cutters leave a finish on the valve seat that is just too rough for good sealing, which is why pros use Neways only for correcting very bad seats, following with stone wheels for the final shaping.

Shim type engines

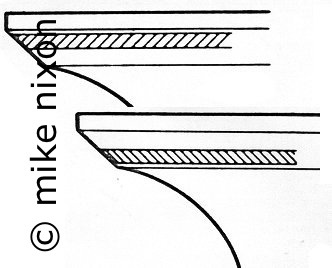

Shim type valve trains, which means most today, are the second most important reason for the disappearing art of the valve job, after cost. Shim engines require specialized technique. The problem is valve protrusion. Valve protrusion is the amount that the valve sticks up above its spring's seat. Every 0.001" cut off the valve seat moves the valve almost the same amount upward toward the shim. This is corrected with a tiny turn of the valve adjusting screw on non-shim engines, but on shim engines a smaller shim must then be found. The problem is shim engine manufacturers offer only so many shim thickness choices, and it is almost inevitable that any cutting on the seat is going to put the resulting valve clearance into the smallest end of the available range. There are no shims left under the factory's smallest for future valve clearance adjustments. This is not acceptable. It's bad practice. And machining shims, as some people resort to, is no solution either. And a new valve will not help because it is the seat that is the problem, not the valve. There is only one way to handle this. The valve must be "tipped," that is, its stem shortened. Tipping must be considered part of a valve job on every shim type engine.

Honda's plated valves

But now we have another problem. In vintage Hondas you cannot tip the valves because they are plated. Tipping would remove the valve's plating, with the result the valve would wear extremely rapidly. This coating is only a few thousandths of an inch thick, not enough to allow removing of some of it during the tipping operation.

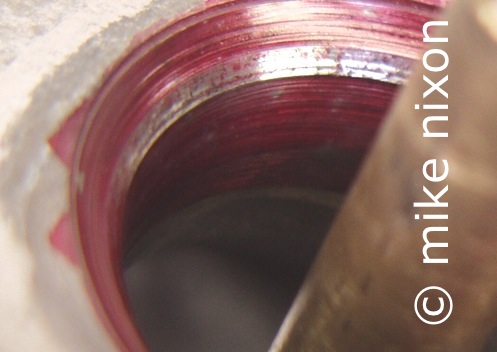

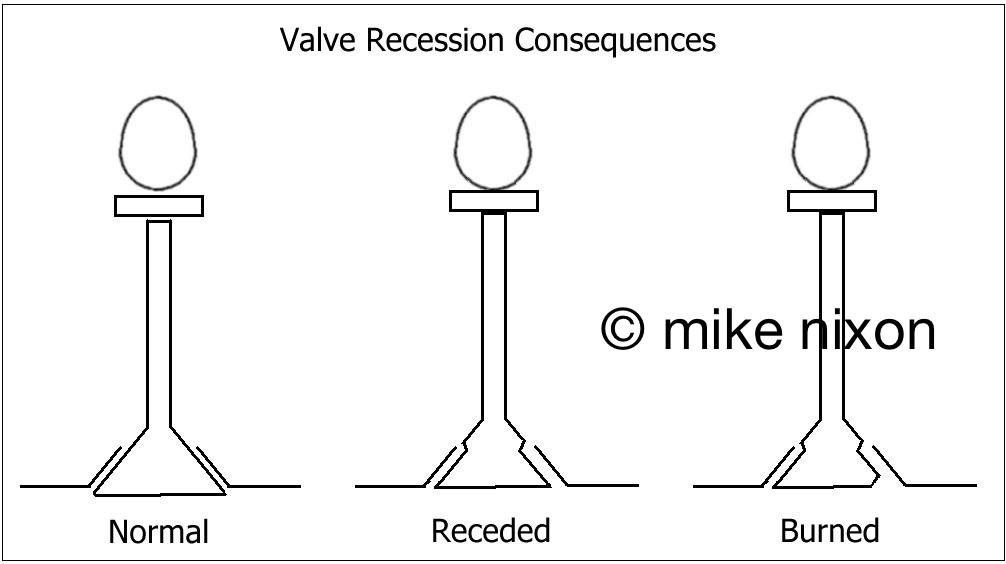

Valve recession

Vintage Honda valves are also plated on their working surfaces, their "faces". Spring forces, combustion's heat and pressure, not to mention its chemical byproducts, and the camshaft's hammer -- all combine to wear this face as the valve pounds against the seat in the cylinder head. This wear takes the form of a ridge in the valve face. In our grandfather's day this ridge was simply ground out every 20,000 miles on a special machine that spun the valve against a super-smooth grinding wheel. Honda's valves up to the mid 1980s cannot be reclaimed this way, but rather must be replaced. The correct way to handle valves that have recession is to replace them. In all engines I prefer as replacements the aftermarket long-wearing and machinable stainless steel valves. On any shim type cylinder head on which valve seat reconditioning is being undertaken, stainless valves are actually mandatory in my view.

Compromises

Now, this doesn't mean I can't appreciate that for many folks making do is the objective. That is, they can't afford new valves or don't have access to the right equipment. Understood. But what I have described here is best practice, the right way, as the article's title says.

Alternative parts

Replacement OEM valves are not always the best option either because they are upwards of $80 each or because they are discontinued. There are aftermarket valves that are almost identical to OEM, at a much lower cost, and as a bonus, are made in lengths consistently 0.001"-0.002" shorter than stock. They are pre-tipped. Unfortunately, they are not tipped enough. The intakes are fine as-is. The exhausts however should be tipped at least 0.005" to be truly useful, because exhaust valve seats get cut more than do intake seats, resulting in more valve protrusion. Another solution is to use thinner than stock valve shims, enabling the completed valve job to live many useful years without running out of available adjustment shims. Undersize shims are available.

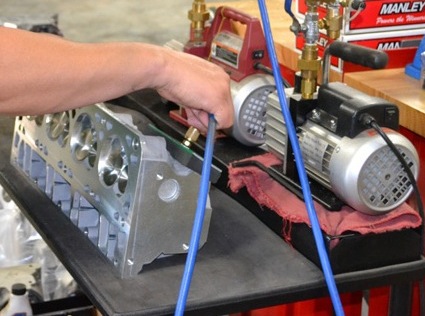

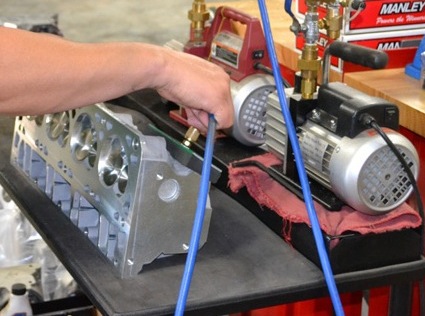

Here is a picture of an automotive cylinder head being pressure tested. You have to understand one thing, no one who goes to the trouble of pressure or vacuum (my preference) testing their valve seat sealing bothers to use Neway cutters in the process of getting there. Not more than once, anyway. Believe it. Here is a picture of an automotive cylinder head being pressure tested. You have to understand one thing, no one who goes to the trouble of pressure or vacuum (my preference) testing their valve seat sealing bothers to use Neway cutters in the process of getting there. Not more than once, anyway. Believe it.

I'm a believer. The head you did for the 750F has now been in service for 2 years. The bike makes just as much (seat of the pants ) HP as the heavily ported head, and gets 44 mpg commuting to work to boot (the other head was good for about 33-5).

John Goulet, MA

|

|

|

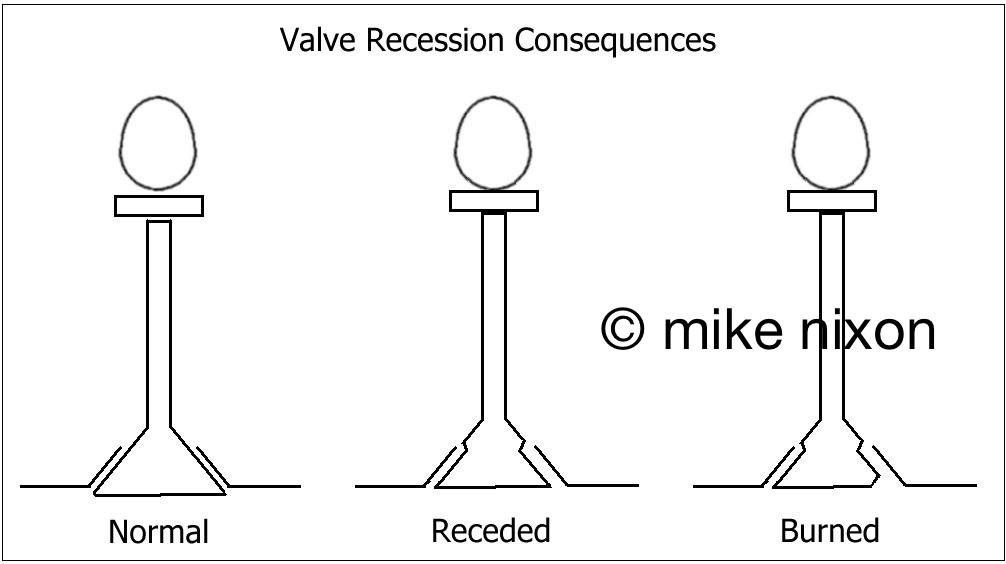

The classic valve recession syndrome. Slight recession is normal. Accelerated recession is common on some Japanese engines. If allowed to go unchecked, that is, uncompensated for with regular valve clearance adjustments, the final result is a burned valve.

Valve job services

Folks are advertising on eBay and elsewhere valve job services. Beware. The heads I saw showed much wider than normal valve seats. Also, glass bead blasting and the use of race-spec fast-wearing bronze valve guides are specifications that are very far from best practice in this industry. Finally, and most troublesome, the mention of machining Honda valves should have potential customers worried. I find it incredible.

Summary

A valve job is inherently a highly skilled undertaking. Additionally, cylinder head work necessarily involves a number of things besides valve and valve seat focus, such as gasket surface prep, oil jet cleaning, thread repair, etc. But the valve and its seat are the really critical things and the reason the head was likely removed in the first place. There is a lot more than most people think to the valve job, and we haven't embarked on spring set up and the like, so there is even more to consider. Don't let the inexpert opinions on forums and elsewhere lead you into complacent ignorance. The valve seat often gets the worst treatment at the hands of mechanics. To sum up, reconditioned valve seats are potentially at odds with shim engine designs, valve lapping is a huge compromise, Neway seat cutters are crude and even dangerous, vintage Honda valves are plated, recession is the normal sinking of the valve into the head, the fitting of stainless steel valves is best practice, pre-tipped aftermarket valves are available for some engines just as thinner than stock valve shims are also. A valve job is not a valve job. Drop me a line.

|

|

Further reading:

Cylinders done right

Cylinder head porting

More on cylinder heads

Engine assembly

Valve seat tool technology

|

®

®

Here is a picture of an automotive cylinder head being pressure tested. You have to understand one thing, no one who goes to the trouble of pressure or vacuum (my preference) testing their valve seat sealing bothers to use Neway cutters in the process of getting there. Not more than once, anyway. Believe it.

Here is a picture of an automotive cylinder head being pressure tested. You have to understand one thing, no one who goes to the trouble of pressure or vacuum (my preference) testing their valve seat sealing bothers to use Neway cutters in the process of getting there. Not more than once, anyway. Believe it.