|

|

|

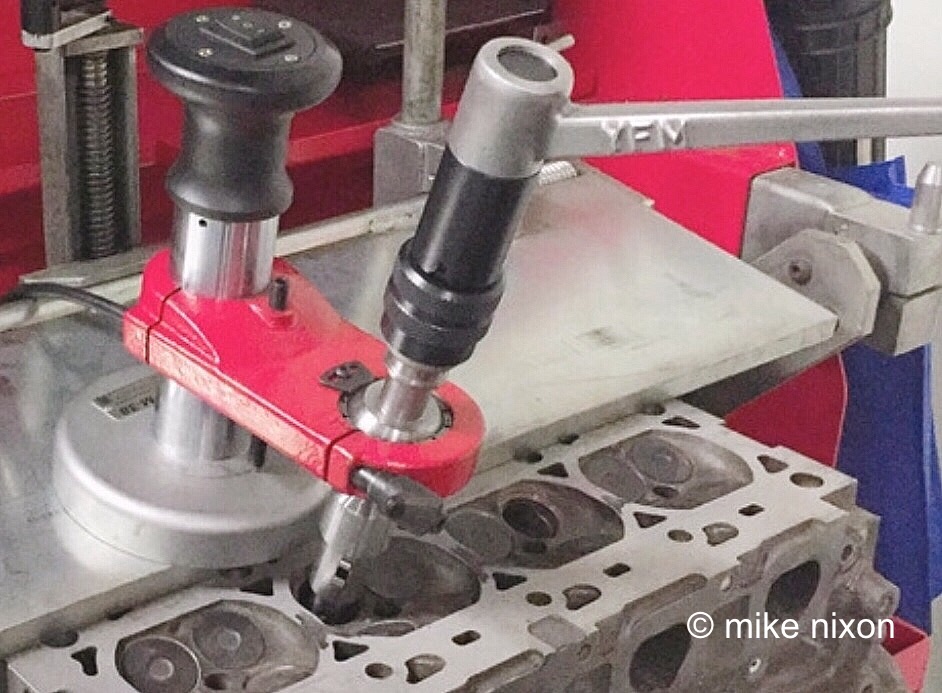

This is the ubiquitous Neway valve seat cutter system. Dead-pilot, guide-loading and an extremely aggressive cutter. And those stupid tapered pilots. Not the best by far, but actually the worst.

|

Valve seat work is somewhat foreign to all but the career tech, so the audience for this article may be small. Those readers who consider themselves knowledgeable will likely be familiar with the Neway valve seat cutter system, but perhaps not even with that--maybe only with valve lapping. Following then is the current landscape of valve seat refinishing technology. For the most part, this examination will be limited to the more affordable, hand-operated equipment.

Valve seat refinishing is necessary because when a valve begins to lose its seal due to wear, the seat (in the cylinder head) has worn also and must be given attention. Seat wear takes the form of a widening of the seat's sealing surface, unevenness, pitting, and in many cases, a heat-induced very slight misalignment of the valve guide-to-seat orientation. The seat is crooked. The problem is, lapping the valve and seat, which rubs away metal from both, does not correct any of these flaws, not even the pitting, the very least of them. Worse, because the valves are usually receded, that is, exhibit a wear ring around their sealing face, lapping is actually counterintuitive as it serves merely to accentuate that ring. It doesn't fix it. There is therefore no good reason to lap valves, no matter how much the practice is endorsed or by whom. Lapping, whether by itself or as one of many steps, is not a valve job. The seat must be refinished-- i.e., remachined.

And here is where the subject gets very broad indeed, because there are many different kinds of valve seat refinishing tools--some good, some excellent, and some, like the Neway system, hardly worth mentioning. 1 The Neway carbide rasp studded valve seat cutter is probably the best known and most widely used, but it is also the worst possible tool for the job. Though a number of things can actually be said against it, the Neway has two very glaring faults. First, the neway cutter rotates on a pilot (shaft) that is pushed into the valve guide and is fixed, or "dead", that is, it does not rotate with the cutter. Because the pilot does not rotate, a means of achieving truly accurate centering is forfeited. This is significant and is a fault that plagues all of the older, traditional hand-operated methods. In addition to the Neway, all the old-time Sioux, Black and Decker, Kwik Way and others all use dead pilots. 2

|

|

|

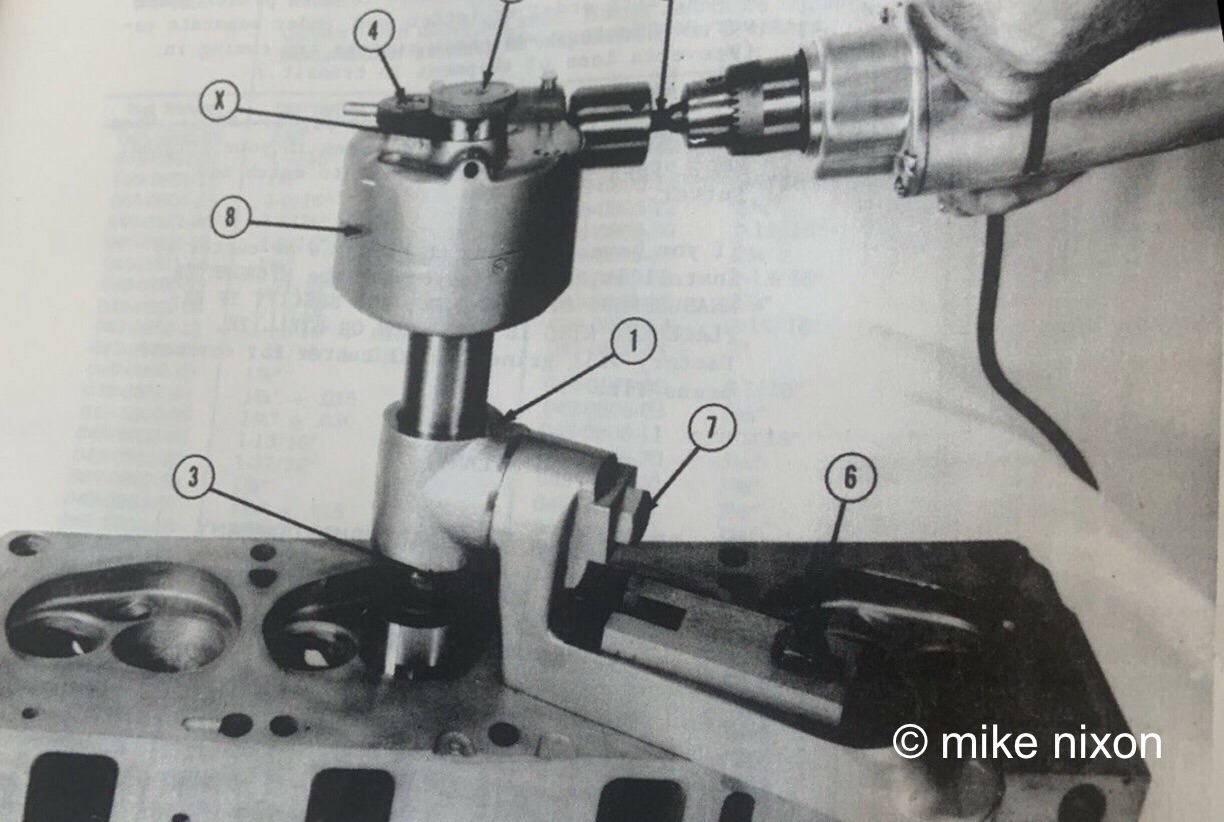

First-generation Kowa, fluted cutter system sold by Honda and Kawasaki as dealer special tools during the 1960s. The Kowa is both guide-locating and guide-loading. But being live-pilot it is superior to many of the systems that were popular in the early days of the automobile.

|

Second, and more importantly, the Neway system, though as with all refinishing methods relying on the valve guide for location, also unfortunately depends on the guide for loading. Location and loading are two different but equally important things. 3 Location is how the tool finds the correct angle of approach. Loading is simply how the tool is locked into that position. In the Neway and several other systems, both location and loading are done at the guide; the cutter's position is held by only the guide. The guide is the bearing in the operation. This is a considerable deficit, because a valve guide has a built-in clearance to its valve of 0.001-0.002 inch. While it might seem accurate enough for locating, the company's tapered pilots ensure failure even in this regard. And as for loading, how can this be a stable platform? The force of cutting inevitably tilts the cutter head out of true with the guide, and thus with the valve seat. Worse yet, if the valve seat has heat-shifted, which is the case often enough, the cutter is even more divergent and cannot correct the bad seat. With no fixed, immovable loading point, all the cutter can do is conform to the seat. The seat will be cut, but if crooked it will stay crooked. If you have performed a valve job on a 70s-80s air-cooled four-valve Honda head, you have experienced this. 4

The solution is a cutter which locates on the valve guide but does not bear on on the valve guide. To do that the cutter has to bear on the head itself, that is, find purchase on the head's gasket surface. This is what all of the best valve seat refinishing systems do and it is what has made Serdi and the other brands that mimick it so successful.

|

|

|

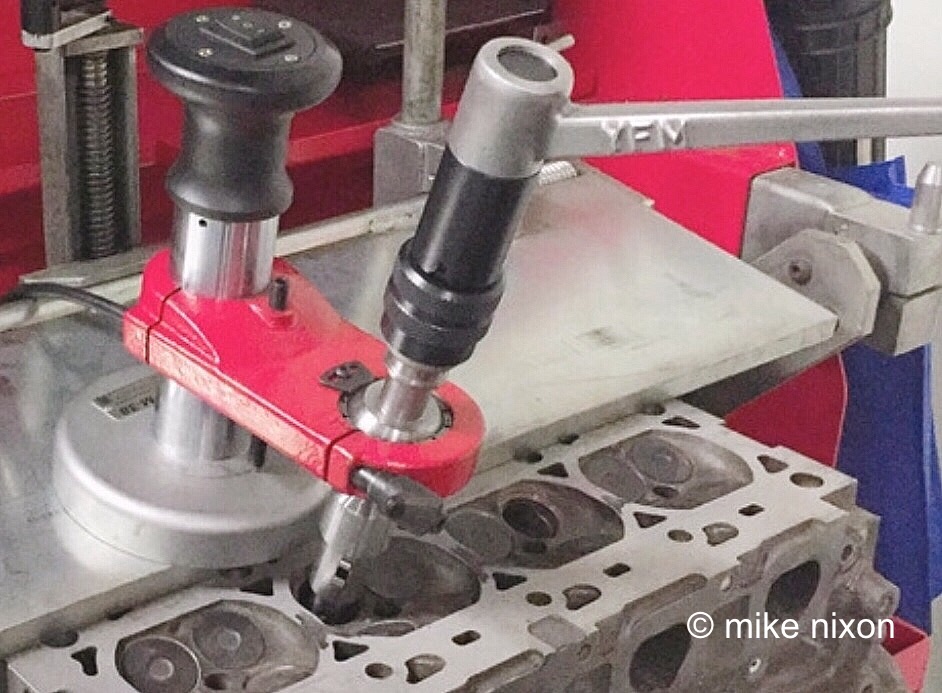

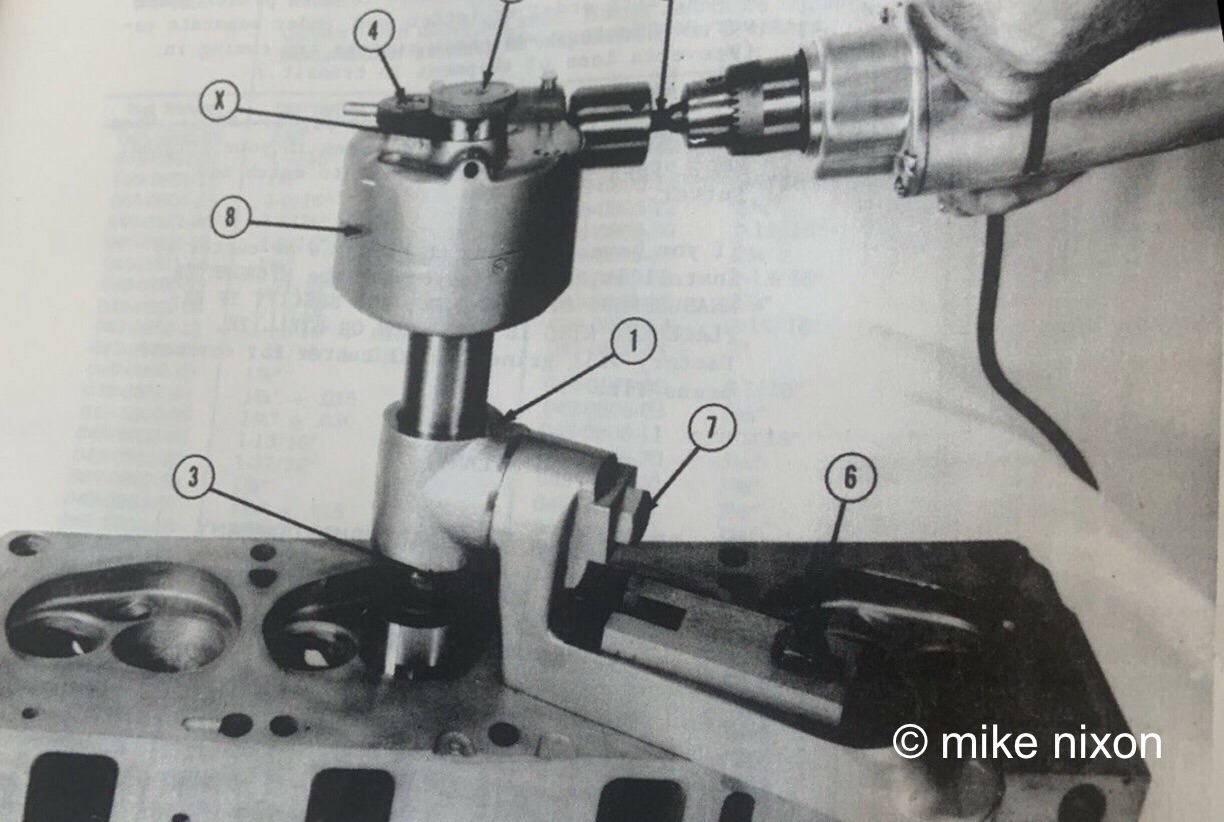

This is the YFM, a Taiwanese copy of the world-famous Serdi second generation system currently the best available in the hand operated category. The Mira, Peg and Manek are nearly identical. The YFM is guide-locating, live-pilot, and head-loading.

|

To summarize, live pilot is superior to dead pilot, and head-loading is superior to valve guide loading. Neway, Sioux, Black and Decker and Kwik Way are all dead-pilot systems. It doesn't matter how elaborate, how large, or how expensive the equipment. If it is dead-pilot it is a 100-year-old design and obsolete because it does not accomodate real-world valve seat issues. Honda/Kawasaki (Kowa), Serdi, Mira, Hunger, YFM, and Newen are all live-pilot systems, i.e. the pilot rotates with the cutter. And the very best systems, such as the Serdi, Mira, Hunger, YFM, and Newen, are live pilot and head-loading.

Head-loading systems have improved in recent years. The issue has been rigidity. Serdi's and hunger's earliest portable units using jointed brackets flexed and thus frustrated all that was otherwise superior in the design. Serdi later changed to an electromagnetic mounting system and this has become the standard throughout the industry, with Serdi's competitors also going magnetic. The cutter loads on the mass of the cylinder head and thus refinishes the seat without the influence of flex.

One further advance is noteworthy. Head-loading (and live pilot) valve seat cutter systems used by production cylinder head shops are available in floor-mounted versions with air tables and even computers for the repeatable high accuracy demanded by these operations. Serdi and especially Newen lead this highest-end segment of the industry. 5

|

|

|

The very sophisticated Serdi floor model, air bag equipped and a very fine tool. The shop grade Serdi is live-pilot, guide-locating, and head-loading.

|

Notes

1-Though there are literally dozens of different ways to machine a valve seat, these can all be boiled down to the two categories enumerated in this article: dead vs. live pilot and guide-loading vs. head-loading.

2-Any tool using a live pilot -- even Honda's pedestrian 1960s-era fluted cutter system -- is vastly superior to any with a dead pilot. The only thing that made dead-pilot systems work adequately despite their flaws was the very loose valve-to-valve guide clearance typical in old car engines that allowed the valve to afterward force-locate on a non-concentric valve seat.

3-Though dead vs. live pilot is important, the industry eventually began to focus on loading, because of valve seat shift. In the Japanese motorcycle world, the Honda CBX1000 is the poster-boy for this issue.

4-In fact, if not for valve seat shifting, rigid-loading cutting systems like the Serdi would likely never have been invented. The valve guide has been both the locating point *and* the loading point for so long--more than a century--that it is only relatively recently that anyone has thought outside that box.

5-Of course, the state-of-the-art floor-mounted computerized Newen is a $100,000 machine. Unique about the Newen among all head-loading systems is that it alone cuts the valve seat one angle at a time, in a contour fashion, by advancing across, i.e. parallel to, the seat profile, a technique they call "single-point" and something that could be done only using computer aid. Serdi and all the other head-loading systems cut all three angles at a swipe, advancing into--actually scraping into (ninety degrees to)-- the seat profile. Both are excellent systems.

|

|

|

The world class Newen computerized valve seat machining system. There is no better solution in the repair and rebuild context. Live-pilot, head-loading, single-point.

|

|

|

System

|

Pilot type

|

Locating

|

Loading

|

Origin

|

Size

|

Note

|

|

Neway

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Portable

|

Serrated cutter

|

|

Black and Decker

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Portable

|

Stone

|

|

Sioux

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Portable

|

Stone

|

|

Honda pneumatic

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

Japan

|

Portable

|

Stone

|

|

Kowa early

|

Live pilot

|

Pilot locating

|

Pilot loading

|

Japan

|

Portable

|

Fluted cutter

|

|

Kowa late

|

Live pilot

|

Pilot locating

|

Pilot loading

|

Japan

|

Portable

|

Diamond stone

|

|

Serdi portable early

|

Live pilot

|

Pilot locating

|

Head loading

|

France

|

Portable

|

Bracketed

|

|

Serdi portable late

|

Live pilot

|

Pilot locating

|

Head loading

|

France

|

Portable

|

Electromagnet

|

|

Mira

|

Live pilot

|

Pilot locating

|

Head loading

|

Switzerland

|

Portable

|

Electromagnet

|

|

YFM

|

Live pilot

|

Pilot locating

|

Head loading

|

Taiwan

|

Portable

|

Electromagnet

|

|

Hunger

|

Live pilot

|

Pilot locating

|

Head loading

|

Germany

|

Portable

|

Articulated

|

|

Kwik Way portable early

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Portable

|

Sioux copy

|

|

Kwik Way portable late

|

Live pilot

|

Pilot locating

|

Head loading

|

U.S.

|

Portable

|

Articulated

|

|

Serdi

|

Live pilot

|

Pilot locating

|

Head loading

|

France

|

Floor mounted

|

Form cutting

|

|

Newen

|

Live pilot

|

Pilot locating

|

Head loading

|

France

|

Floor mounted

|

Contour cutting

|

|

Peterson

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Floor mounted

|

Form cutting

|

|

Sunnen

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Floor mounted

|

Form cutting

|

|

Rottler

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Floor mounted

|

Form cutting

|

|

Kwik Way

|

Dead pilot

|

Pilot locating

|

Pilot loading

|

U.S.

|

Floor mounted

|

Form cutting

|

|

|

This is the earliest Serdi portable. I have experience with this model. Note all the brackets and lightweight mounting parts. Later versions are superior.

|

|

|

|

The late Kwik Way portable. I have never seen one of these. However, it does look as if this head-loading system would be good quality.

|

|

|

|

The Hunger, by Ludwig Hunger, Germany. This is ball joint based. Lots of these on ebay.

|

|

|

|

|

|

The classic, ubiquitous Sioux/Black and Decker motor and stone system, the oldest, most recognizable tool for valve seats. But nearly the worst, too.

|

|

|

|

Same as the late Serdi, Mira and YFM portables, this format is so successful it is copied all over the world. This is the Chinese brand Manek. I own a Mira. Live pilot, guide-locating, head-loading.

|

|

|

|

The late Kowa with diamond stone. This is the current Honda and Kawasaki official dealer tool. I have used the heck out of these, and if seat drift is not a challenge, this works very well, despite this system's guide loading.

|

|

|

|

|

|

An early 1980s Honda special tool, this is essentially Japan's version of the ubiquitous Black and Decker/Sioux dead pilot, pilot locating, pilot-loading system and therefore unfortunately for all its glamour, a very low-quality system.

|

|

|

|

This is a second or third generation Mira portable. Guide-locating, live pilot, head-loading.

|

|

|

|

An old-school Peterson floor mount. Like the Sunnen and others of this era, this system is dead-pilot, guide-locating, and guide-loading.

|

|

Last updated March 2025

Email me

© 1996-2025 Mike Nixon

| | | |

®

®