® ®

|

The CBX valve job |

|

So I received this CBX head for a valve job. I have done many of these, both separately and as part of engine rebuilds. My first surprise was how new the valves looked. Not a hint of recession. Very unusual. And more so because my customer told me the bike has over 30,000 miles on it. I said well, the valves have been replaced then. No way these have even more than 10,000 miles let alone 30,000. |

|

|

|

This is not a 30,000-mile CBX valve! It looks new. Hmm. |

This is a 25,000-mile CBX valve. Very typical recession. The valve is not reusable. |

And this is not a 30,000-valve seat. But it is a very odd looking one. Note, hugely wide and only one angle. |

|

|

|

|

Look how much material had to be machined away from the seat to return it to the normal width. |

A professionally machined valve seat. Compare this with the one above. |

Comparison of the refaced valve on the left with a non-molested valve from another engine on the right. Note the different thickness margins. |

|

|

Then he says the head had a "valve job" a year ago, and he's sure the valves have never been replaced. Thinking about it, I am pretty sure too. They haven't been available from Honda for more than a dozen years now. And these are definitely OEM. Hmm.

On closer inspection, I see that the valve stems show some wear. New, but not new. This engine is trying to tell me something. Then the light went on. These valves have been ground! I was stunned. Absolutely gobsmacked. It never occured to me someone would reface stock Honda valves. You can't do it. From the earliest days until midway into the 1980s, Honda's valves were plated. Those soft valves recede like hell even with the plating, imagine what they will do with it removed!

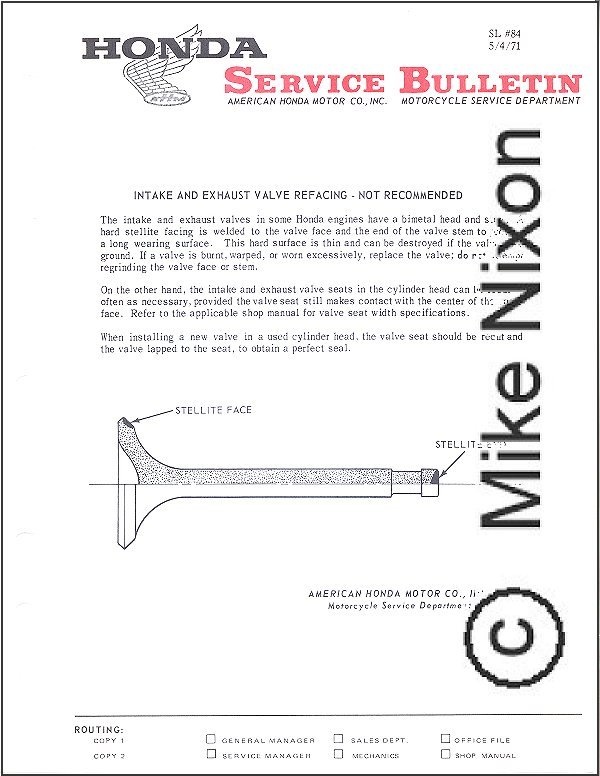

The official 1971 service bulletin shown above tells us about the plating and warns against refacing, while career Honda mechanics' exposure to the product proves the soft valves go back to the beginning, before even 1960. But no getting around it, I'm looking at ground Honda valves! Incredible! To make sure I put another CBX valve up to one of the customer's. Yup. The margin is smaller on the customer's valve! The face has been ground.

And that's not all. Just as butchered are the valve seats. They've been subjected to a Sioux automotive valve seat grinder, used by an ignorant person. Ignorant for using a Sioux tool. Ignorant for using it incorrectly. And if it was the same person who ground the valves, ignorant for not knowing Hondas. And look how much the seats were hacked up! It is a given the valves will need considerable shortening to compensate for the head machining.* Good thing we're using Kibblewhite valves. Stainless steel valves can be shortened, stock and Chinese replacements cannot.

The moral of this story is this. There is a ton of work in a CBX head when it is getting a valve job. Not only proper valve inspection and selection, but also sophisticated, professional, multiple-step machining of the valve sealing places (seats) in the head. Not the Sioux zoom and done. Add to that the best practice of shortening the valves to maintain the proper adjusting shim range and you'll see this is not a task for the non-professional unskilled person. The bottom line is, if you pay less than $3000 for a CBX valve job, you are getting inferior work.

* Turned out this head had the opposite problem. Someone had replaced all the exhaust valve seats! So that, all the exhaust valves had too little protrusion, not too much! Proper exhaust valve clearancing was as a result a challenge. In more than fifty years at this, I have never seen valve seats replaced in a Honda cylinder head. Though not unusual in racing engine work, it is very rare otherwise.

|

|

Last updated January 2026 Email me www.motorcycleproject.com My bio © 1996-2026 Mike Nixon |