® ®

|

Early Honda V4 Cams: What Really Happened

Revised |

|

The first-generation Honda V4s were and still are magnificent testimonies of Honda's engineering prowess. From a sociological standpoint, the bikes attracted some interesting people fervent about their riding. This group has contributed significantly and meaningfully to the web community, and it is blessed because of this. One aspect of these bikes that is thoroughly represented is the issue of camshaft failures in the earliest models. Unfortunately, like so much that is "common wisdom", most of what is said about the subject of first-generation Honda V4 cam failures is fallacy. |

|

The Internet is at the same time a blessing and a curse. A blessing because it quickly codifies major thought streams on a subject. But a curse also because often the user forum organism breeds a decay that necessarily colors and constrains the collective information. The result is a one-dimensional thinking that regards problems in very superficial ways that are often ill-informed. The fact is, despite much that can be read on the net, the controversial first-generation Honda V4 cam failures are not explained by anything as simplistic or as singular as lubrication. In fact lubrication doesn't enter into the picture at all. There are actually four critical ingredients in the extreme camshaft wear issue. |

|

Ingredient 1: Historical Asian cam construction. Aftermarket cams are made in a number of ways, but production Japanese camshafts are pretty consistently metal castings. Cheap, in other words. This means most production Japanese cams are cast steel. The very best production cams are cast moly (in the Kawasaki ZX-10R and other sportbikes, for example). But far and away, street bikes have cast camshafts. It may further surprise you to learn that production camshafts are not hardened very hard. Don't believe it? You can actually drill a camshaft from a 70s or 80s Japanese street bike, and you don't even need a fancy cobalt drill bit to do it! A sharp HSS (high speed steel, the standard drill bit material) will drill a cam lobe very easily. This is probably why the cams in most 70s-80s Japanese multis wear pretty steadily, a documented 0.001"-0.005" for every 3,000 miles. Most mechanics are aware of this. And experienced machinists will recognize those distinctive cast-metal chips. Cams wear relatively quickly. Moreover, Japanese engine manufacturers cast the cams extremely close to final dimension, then very lightly grind them to size, because a manufacturer producing 15,000 vehicles doesn't want to waste much. And, even more importantly, he doesn't want to grind through the surface hardening (cams are not hardened as the last step but as an intermediate step, so warpage can be corrected after by grinding.) In other words, the grinding aspect of cam manufacturing just barely cleans them up. Which is okay, except when it isn't. |

|

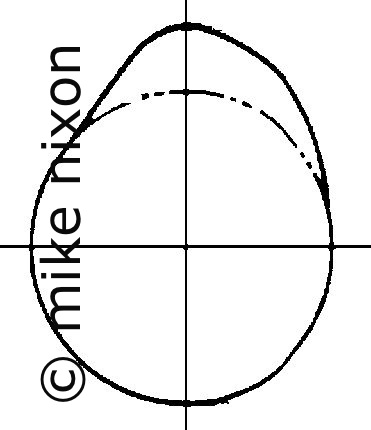

Unfortunately, cams made this way tend to have defects in the metal just below the surface, because most of the metal's impurities migrate toward the surface in a casting, even with modern technology. The very slight grinding doesn't go very far below the surface and therefore doesn't get past and remove these defects. Engineers call these pockets of impurities "inclusions". It's an inevitable part of castings. This cam is from a Kawasaki GPz900, another machine with the same cam problems as the Honda V4. And for the same reasons. |

|

Ingredient 2: Plated cam followers. The cam's followers (rocker arms) on the other hand are extremely hard. It is common machine engineering practice to have two close-working parts be one soft and the other hard. Thus the cams are pretty soft, and the followers extremely hard. The cam does most of the wearing in other words. The follower wears only if the camshaft wears severely, or the engine is run low on oil. Otherwise, not. However, the follower is not hard because of superior material, but because it is plated. Many of Honda's rocker arm type engines have their rocker arms or followers hard chrome plated, chromium being an extremely hard material, thus long-wearing. But don't confuse hard chrome with decorative chrome. Same metal, different process. When a part such as a handlebar is decorative chrome plated, it is plated first with a softer metal such as copper (and often tin below that), then the chrome is put on top of the copper. The copper plating gives the chrome depth, and adds gloss as it fills in tiny imperfections in the base material. |

|

Hard chroming on the other hand is simply putting chrome on top of the base metal, with no undercoat, which is why it is much rougher looking and was early on called "flash chroming". Your bike's transmission shift forks are also done this way. |

|

Ingredient 3: The emergence of high valve lift. Honda for decades was very conservative with valve timing and lift specs. Honda's 1970s era bikes have only 5mm (less than a quarter inch) of valve lift, and timing numbers in the 5-40 range (giving just 225 degrees open duration). Very mild cams. Until the mid 1980s. You can't appreciate how extremely moderate this was until you look at Kawasaki and Suzuki specs from the same era, typically 7mm lift and 15-55 timings. In fact, you can rev an old Honda SOHC four to the moon, way past the engine's redline in other words, and the valves will not float (that is, overpower their springs and flail around and tangle). They're just not working hard enough to. (I am not recommending this practice, for the record.) Modern higher lift cams require stronger springs to avoid valve float. Later, Honda started creeping toward higher lifts and the first major production U.S. model street Hondas to reach into the 10mm zone were-- you guessed it-- the 1982 Magna and Sabre. |

|

Ingredient 4: Tandem cam followers. Coinciding with the company's advent of high performance cams was Honda's move to dual followers, that is, one cam lobe operating two valves in a four-valve cylinder head. Honda had used dual followers before, in fact, in its debut four-valve head on the 1972 XL250. But remember, the XL250 engine, like those that would follow for the next ten years, lifted its valves only 5mm and didn't rev all that much either. What dual followers did, back then but more importantly later in the V4, was greatly increase the specific loading of the cam lobe. Now instead of two valve springs, four springs bore against the cam lobe. And in the case of the early V4, these springs were unprecedentedly strong ones (because of the high lift, remember). |

|

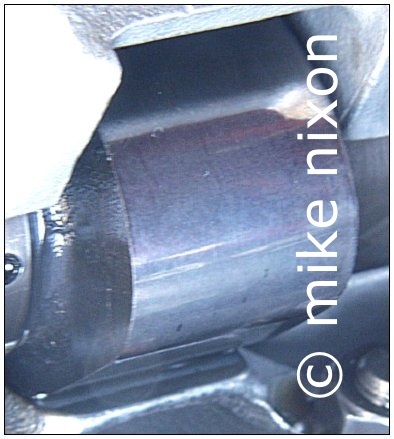

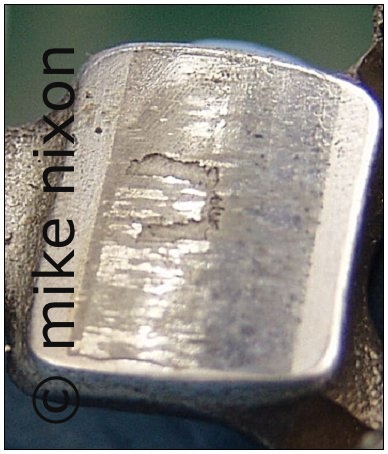

How do these four things-- cam manufacture, chromed cam followers, tandem follower design, and high valve lift --combine to destroy the first-generation Honda V4 cams? In normal use the cam wears, and the hard chrome plating on the followers scuffs just perceptibly, as the engine accumulates miles. Normal. This example is typical. Nothing to be concerned about. I have seen engines with 50,000 miles whose followers looked like this one. A fingernail run along the follower does not pick up any damage on the part. |

|

However, the wear in the cam follower is much more severe if the camshaft has inclusions, that is, pockets beneath the service that appear after a few thousandths of an inch wear. Very small inclusions have little or no effect. The cam is not in trouble, and will likely live a long and happy life. Like the example shown here. |

|

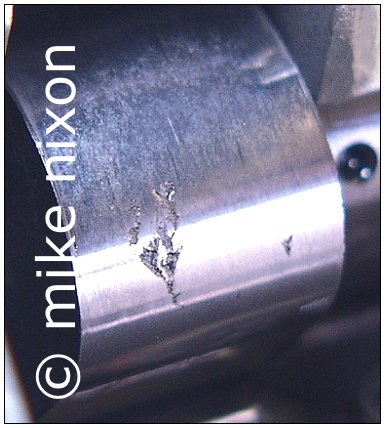

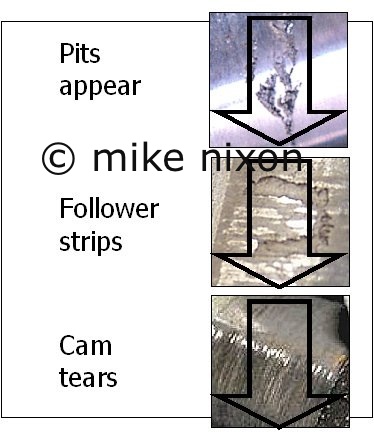

But if the pits are large and/or cover a significant portion of the cam lobe, the lobe becomes abrasive (can you see it is already starting to be ground up?) to the point that... |

|

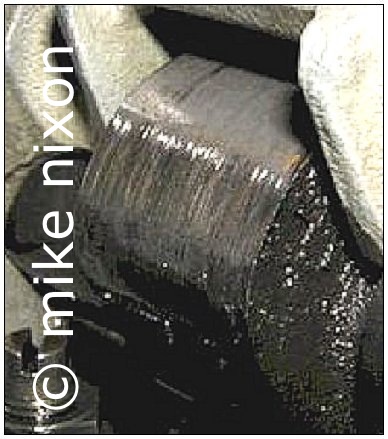

...it begins to abrade the hard chromed follower (rocker). The follower's chrome overheats and breaks down, and actually buckles, splits, and begins to flake away. The hard chrome begins to come off the follower in strips. The follower is now a high-speed cheese grater, and with its surface being much tougher than that of the cam, it eats the cam for lunch. This is the point of no return. |

|

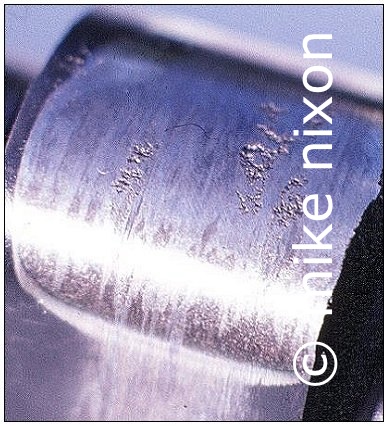

The surface on the follower pictured immediately above is a rasp-like texture that will be forced against the soft cam lobe. The cam quickly tears up. If unchecked, the lobe can even be worn completely away! This example is almost to that point. Unbelievable! And extreme. Few cams ever get to this point. This rider has to have ignored the situation over a long period of time. |

|

So the chain of events is: Pits develop on the cams and if bad enough they excessively abrade the followers. The followers then in turn strip off pieces of their chrome. The resultingly raspy followers then chew up the cams. And it all begins with the pits. |

|

The problem isn't poor oiling. I have nothing against the many oiling line kits out there. But the idea for these kits came from a different problem altogether, one experienced by racers (including myself) having to do with cracked tube steel cylinder head oil lines. Team Honda and others did not install special oil lines in their Interceptor racebikes for inadequate oiling reasons, but because the stock rigid steel tube oil lines didn't stand up to racing conditions. Nor was the problem petroleum based engine oil. It's not oil-related at all. This is precisely why some first-gen V4s have cam problems and some do not. It was all up to the happy coexistence of cam and follower, which in turn, again, goes all the way back to a minimum of cam inclusions appearing during the normal wear process. |

|

And it isn't improperly adjusted valve clearances, despite Honda's effort at blaming their dealers and diverting attention with their goofy cam tool. Typical corporate nonsense, that. Total subterfuge. Honda even eventually admitted in two issues of a mechanics newsletter that use of the tool is optional. |

|

Nor was it badly made camshafts. They were made no differently than Honda made cams for any of their other models. Though some attempts were made by Honda to have new cams solve the problem. For the 750 alone Honda issued several revisions to camshaft finish, a few of them shown in this picture. Note the darker colors indicating various surface finishes. They were countermeasures, but they were all bandaids, stopgaps. And really, hopeless. |

|

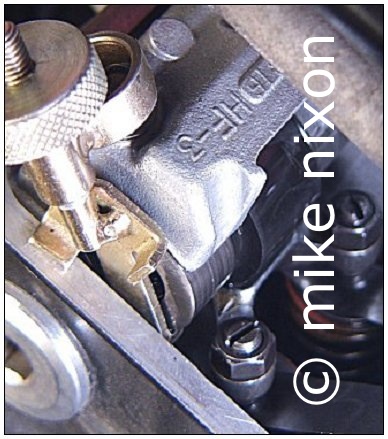

The way to fix the problem is to go after the cause. Look at the followers first. If their chrome plating isn't stripped, good! Then look at the cams. If the followers aren't stripped and the cam shows only normal wear, you're good. But if the followers are stripped, no matter what the cams look like, get all of that mess out of there and have both cams and followers hard-welded. Megacycle offers this service, and it is the best solution to the problem. This eliminates the hard chrome that can strip off, and provides a hard, durable surface that is very much more difficult to hurt. This cam follower is a part going into a V65 I restored several years ago. |

|

This cam went into the aforementioned V65. It was hardwelded then reground to stock specs at the same time that the followers were done. |

|

|

Postscript 2014: In an ironic twist of reality, user forum members have responded to this article by accusing me of being a shill for the Megacycle company. Wow! I am not advocating Megacycle or Webcam. I am simply showing what any thinking person should recognize is the problem and identifying the only real solution. Follower hard welding has become a pretty significant practice these days due to the chroming ethic Japanese manufacturers defaulted to and its inadequacy. Take advantage of the fix that is available.

Postscript 2017: Recently I have observed that cam makers insist that any cam they produce intended for a rocker arm type engine be accompanied by hardwelded rocker arms. This undoubtedly is a result of their newly-made cams being hurt by old, scarred rocker arms, but the point should be obvious. In fact, more than one. First, the chromed follower (rocker arm) is the initiating part when it comes to cam lobe/follower wear. Two, even light scuffing on a follower can ruin a newly-manufactured cam. And third, please note that while both Megacycle and Webcam insist on hardwelded followers to eliminate the at-risk OEM plating, neither make any overtures regarding lubrication.

Postscript 2018: I have witnessed that SOHC fours are also ideal candidates for the remanufactured follower, whatever cams are used. It is now standard procedure to have the same work done on them as is done on first-generation V4s, though the SOHCs don't eat their cams as readily as do the V4s.

|