|

|

|

|

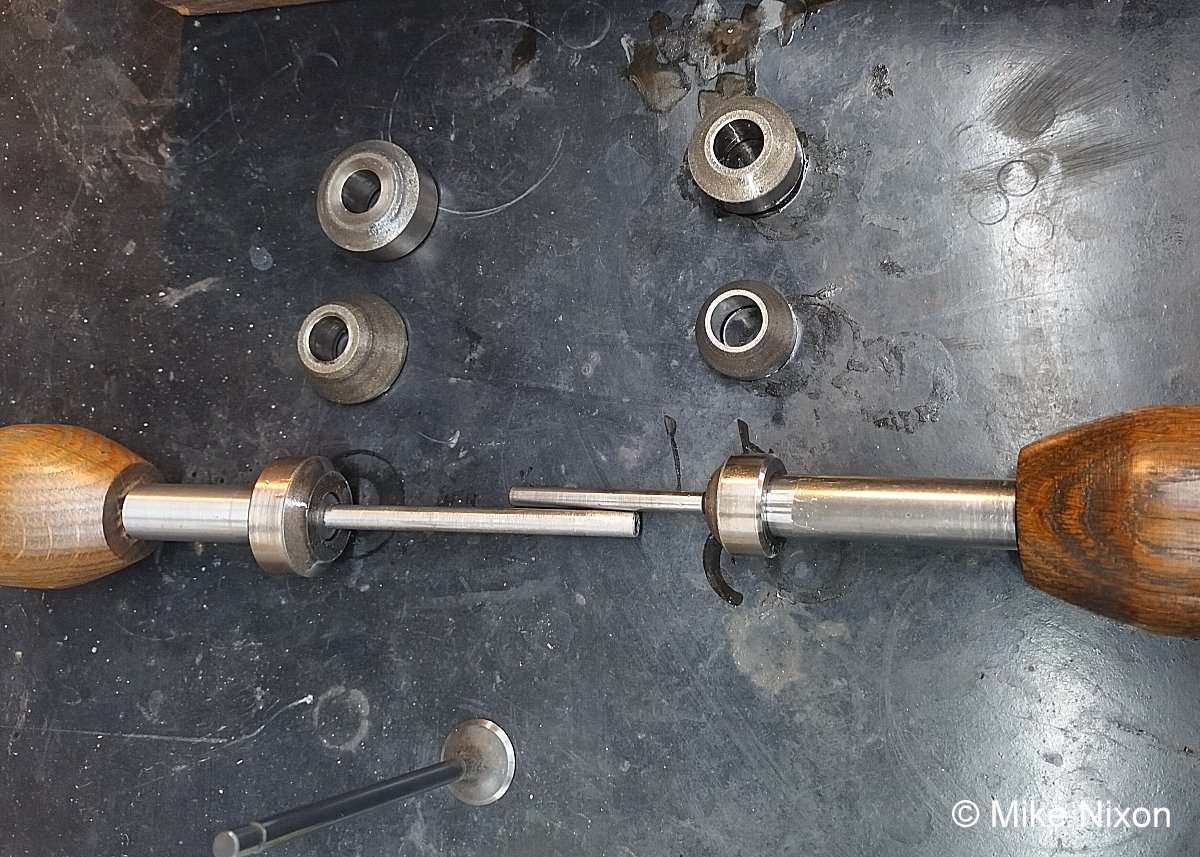

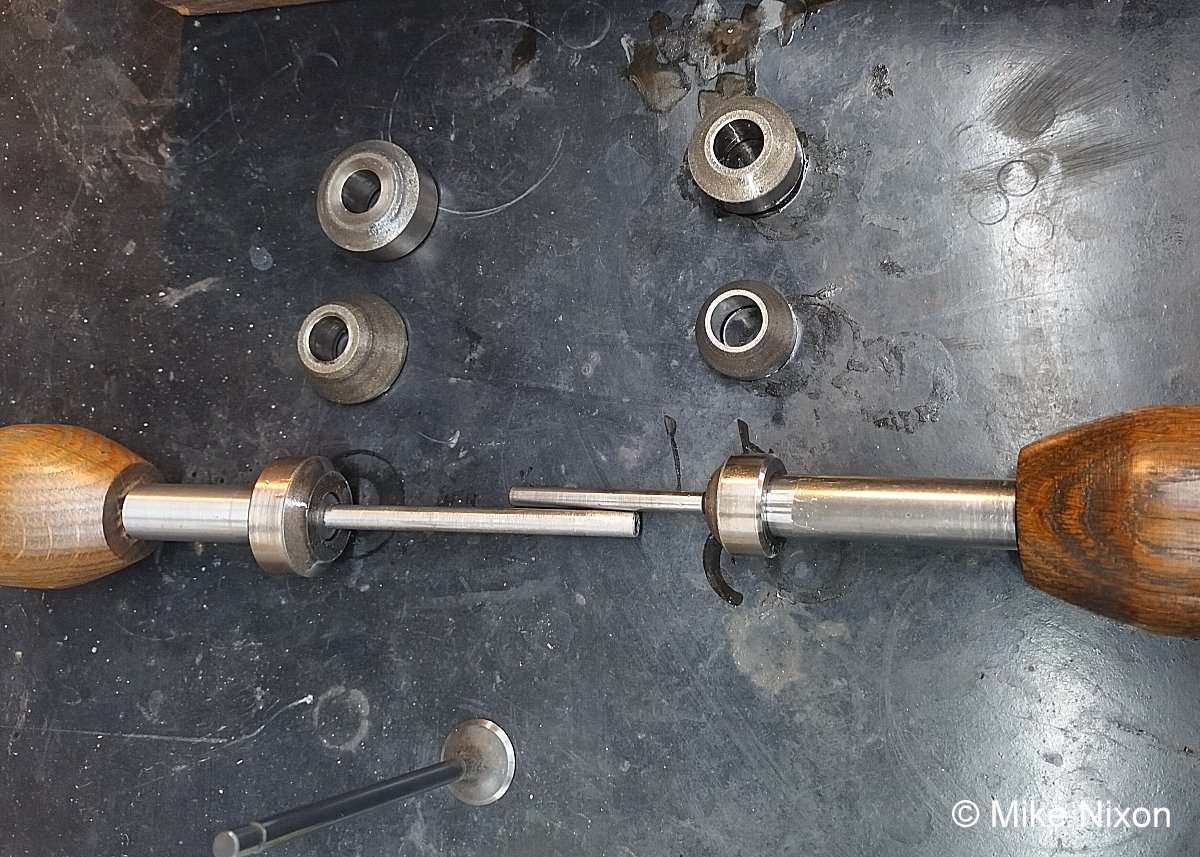

This Honda SOHC 400 three-valve-per-cylinder head has valves with different size stems, thus two different tools are needed, and of course six seat cutters, three for each of the two valve sizes--45, 60 and 32 degrees.

|

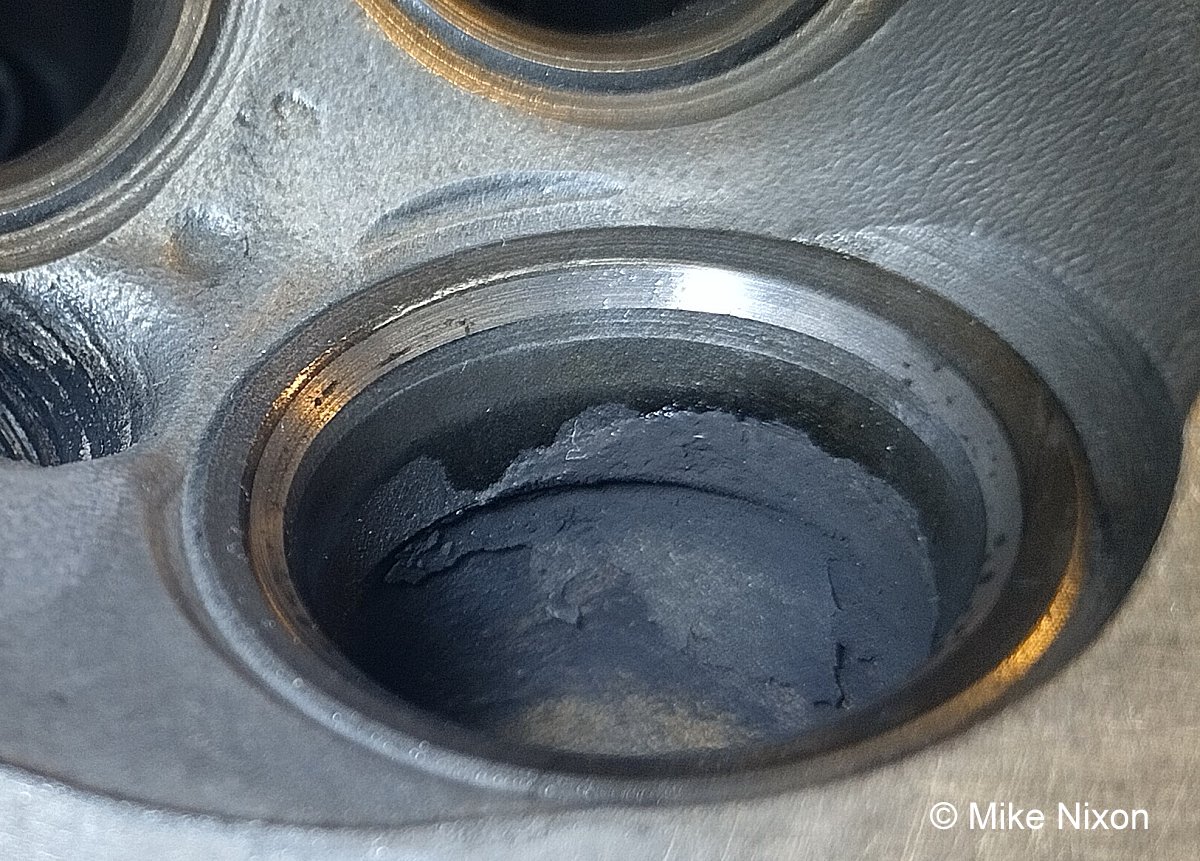

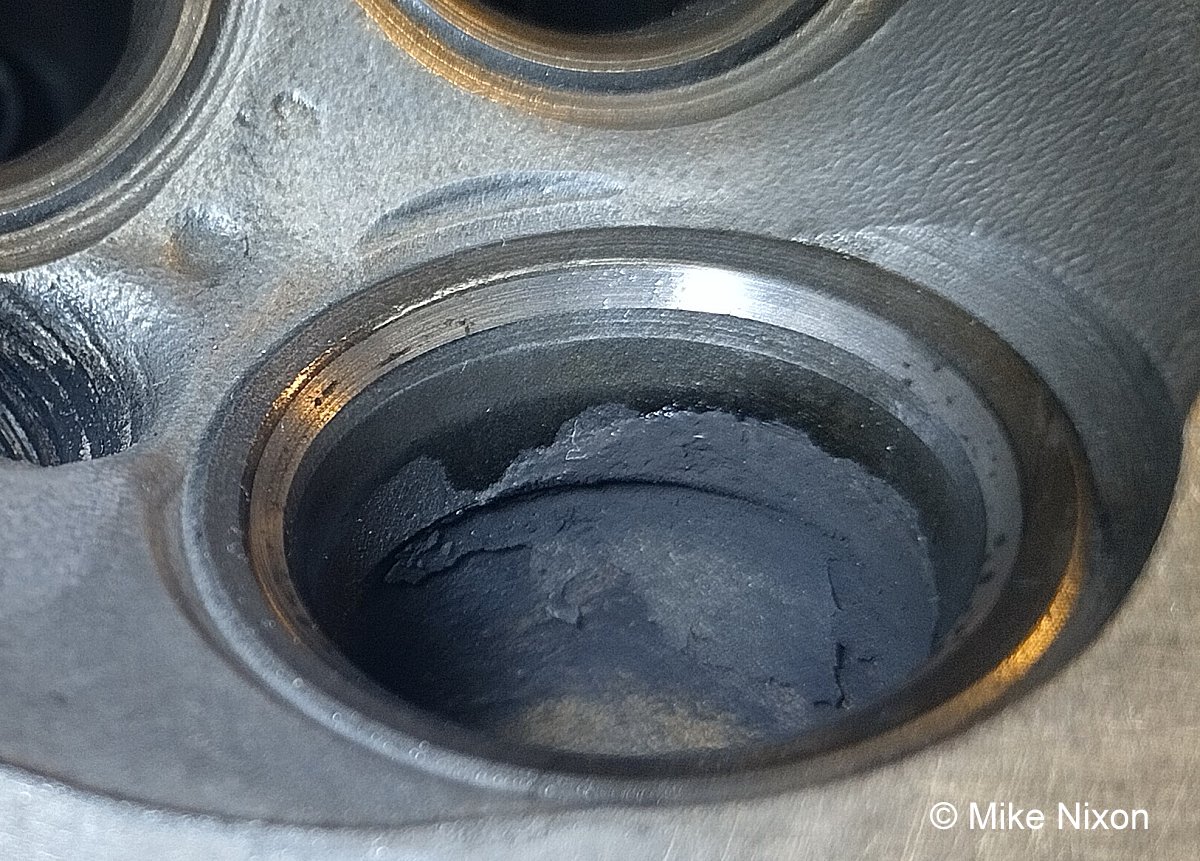

The first cut is the 45 degree. This results in a new sealing surface and removes the seat's pitting and unevenness. It's a good start as the 45 is the most important, where the valve actually seals in the head.

|

Note the finish in this closeup. Smooth, even, straight. Geometrically perfect. The basis for the whole job.

|

|

|

|

|

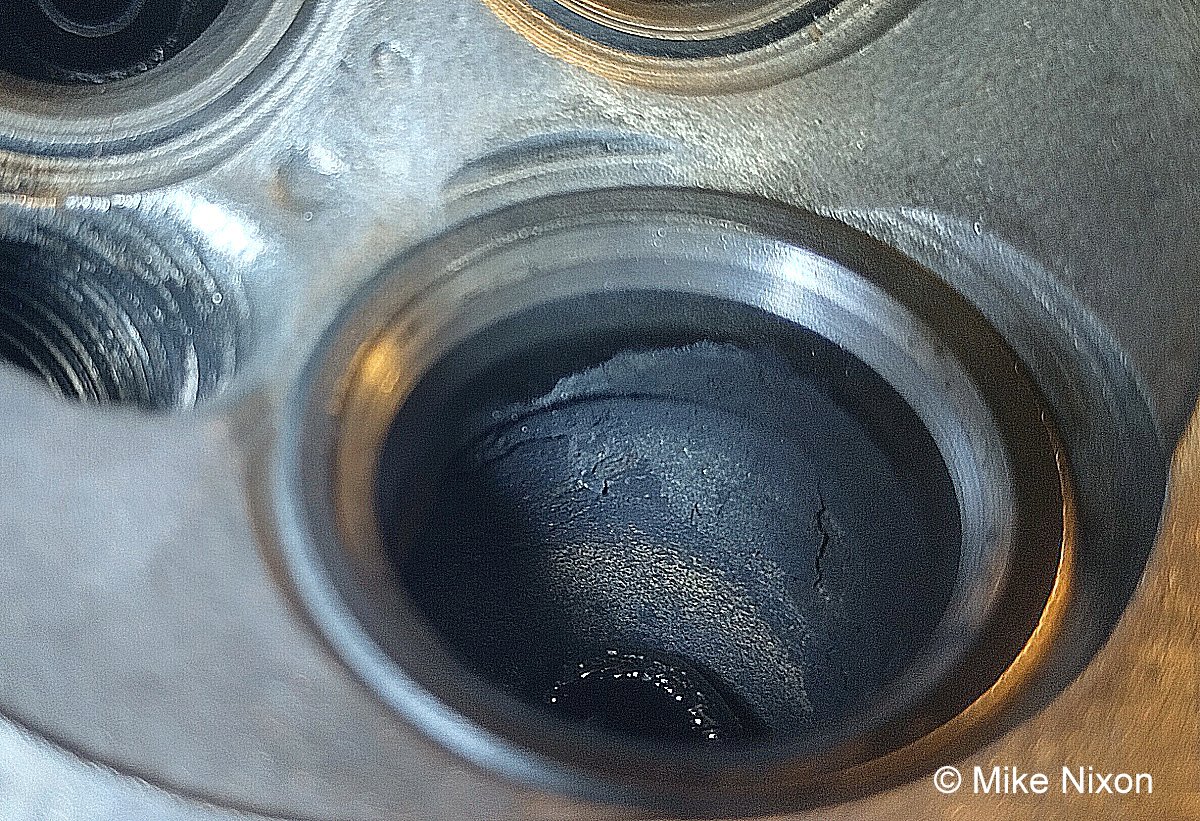

There is an ideal width for the 45 angle based on the diameter of the valve. This 45 was too wide even before it was cut and now it is even more so. Pretty typical at 30,000 miles. Therefore the next cut is the 60 degree, which will narrow the 45.

|

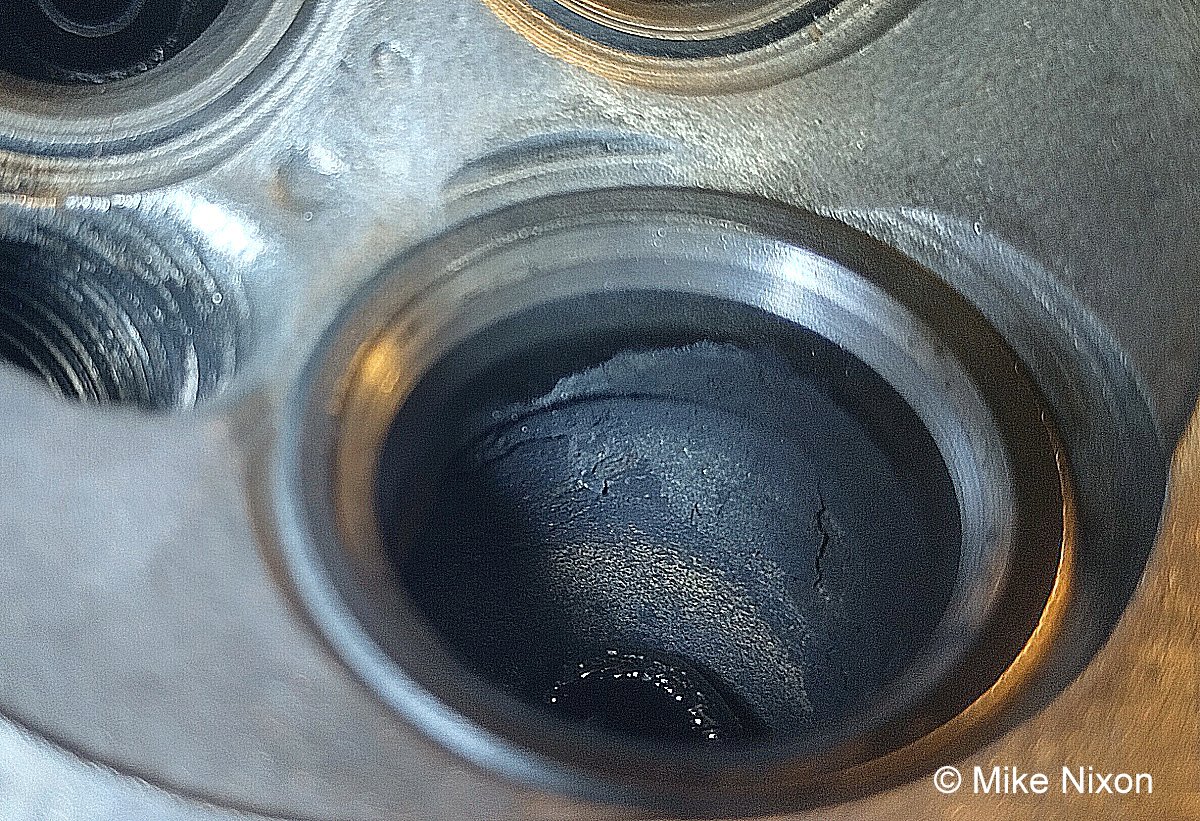

This is followed by the 30 degree cut, which further narrows the 45, but now from the combustion chamber side so the all-important 45 stays centered. At this point, all three angles have been machined, but this is only preliminary. More machining may be necessary to optimize the seat, depending on the next step.

|

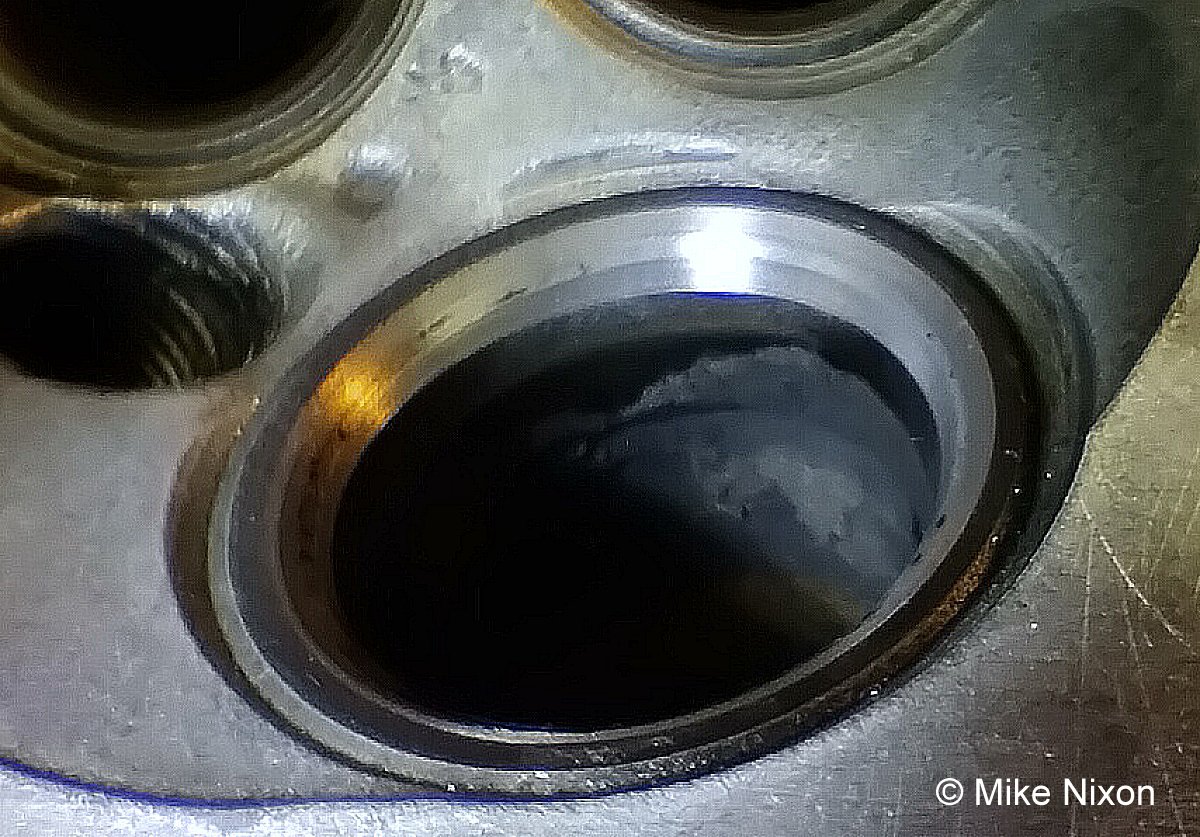

Now we check where this newly-machined seat meets the valve's face. Prussian blue is lightly smeared on the seat and the valve plopped on, and this shows that the seat is meeting the valve where it should--exactly in the center. If the contact ring was not centered, then either the 60 would be used to move it toward the combustion chamber, or the 30 to move it toward the port, until it was centered.

|

|

|

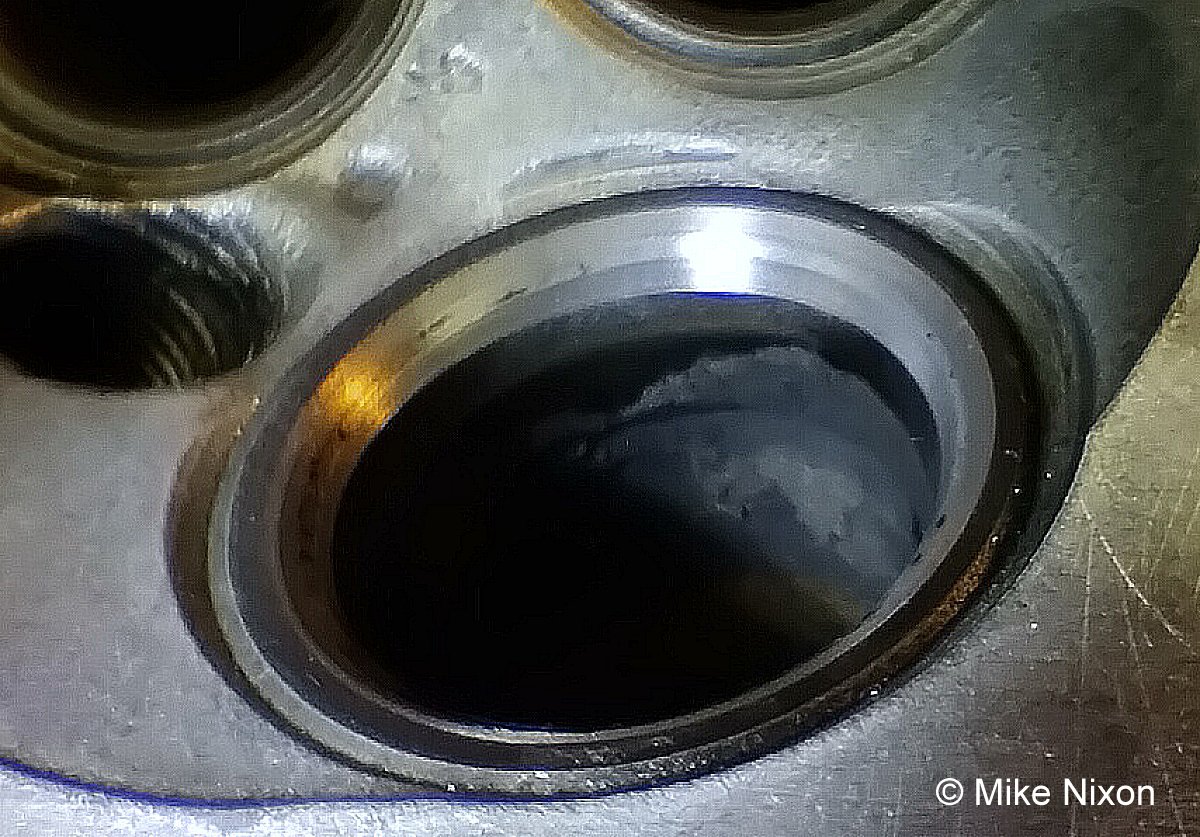

Once the 45 is centered, the whole seat is painted with a metal dye and the 45 angle is then carefully machined to give a clear indication of its width. If too wide, the 60 and 45 and both employed to narrow it. If on the other hand it's too narrow, then the 45 is simply machined a little more, which--since it is an angle--widens it.

|

|

®

®