|

|

|

|

This is my cylinder machining center. An excellent quality dedicated cylinder boring machine and the tooling to do everything it needs to do. The machine is made in the U.S. and is the industry-preferred equipment.

|

This part is important too. That's actually a vintage, adjustable height doctor's exam stool. Cool stuff. Makes for very pleasant work in front of the cylinder boring machine.

|

The cylinder assembly is prepped by removing the alignment dowels and making sure the base gasket surface is clean and flat. Mounting in the machine is critical for accurate machining.

|

|

|

|

|

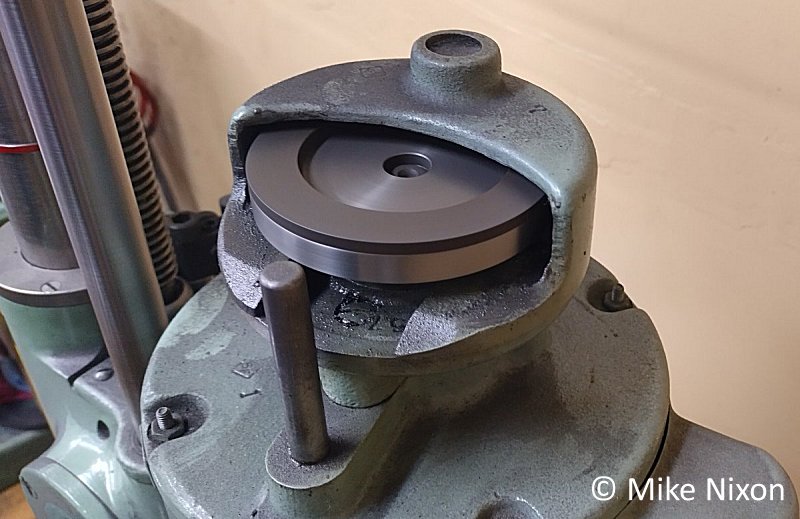

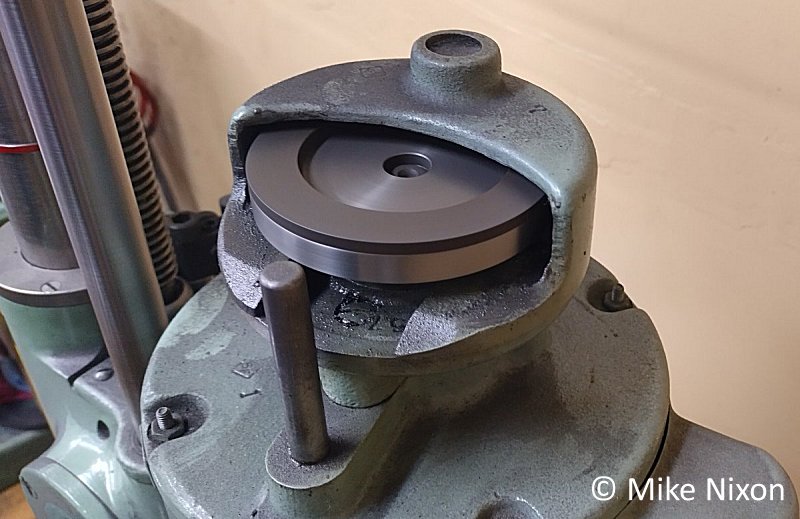

One of the secrets of using a machine like this is that the cylinder assembly is mounted upside-down in the equipment to take advantage of the cylinder casting's base gasket surface, the most critical reference point because it establishes squareness.

|

The upper parallels the cylinder assembly mounts to must be accurate and in good condition, and they must not touch the sides of the cylinder sleeve.

|

Looking underneath the cylinder, note that the lower parallels are tightened up against the edges of the cylinder sleeves. This is a must for most vintage Honda cylinders as they can otherwise loosen during machining.

|

|

|

|

|

Still underneath, the cylinder clamping plate is gimboled to ensure even clamping force and thus a very accurate mounting of the cylinder assembly into the machine.

|

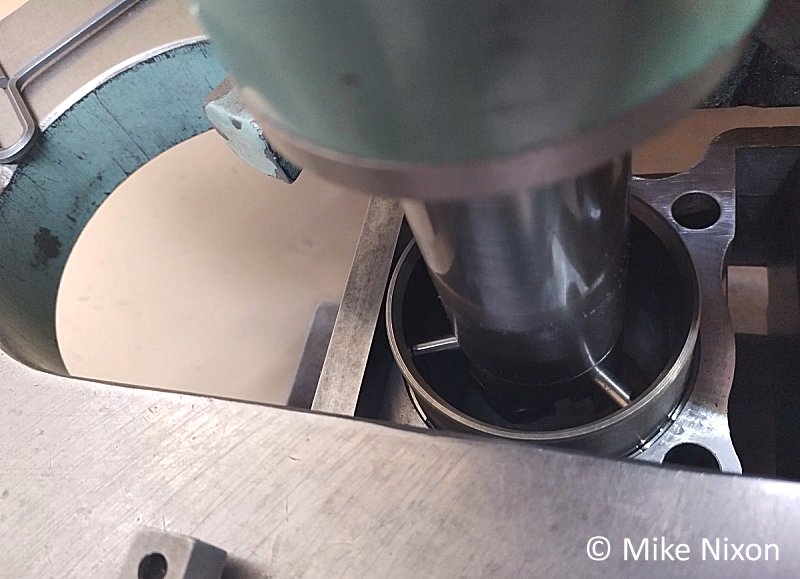

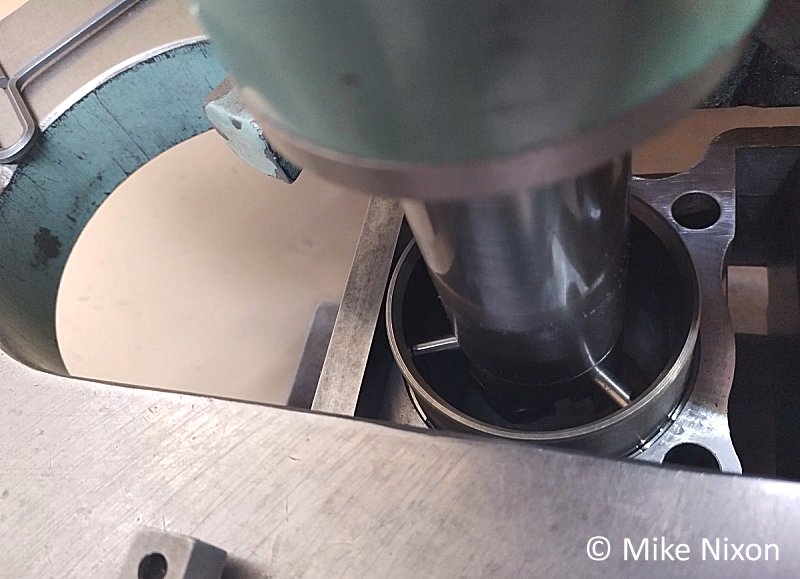

After the cylinder assembly is properly mounted, the boring bar is centered in the cylinder by the use of the machine's three centering fingers.

|

A proprietary carbide-faced cutting bit is prepared. The machine can accept only those bits made for it. There are five different lengths available.

|

|

|

|

|

There is a diamond lapping wheel attached to the machine for sharpening the cutter bit.

|

A special micrometer is also a part of the machine so that very accurate cuts are possible.

|

In this picture a 0.003" cut has been made to test the centering of the cylinder. Notice that the cylinder exhibits some uneven wear at its top.

|

|

|

|

|

The second cut completed the making of a perfectly straight and round cylinder.

|

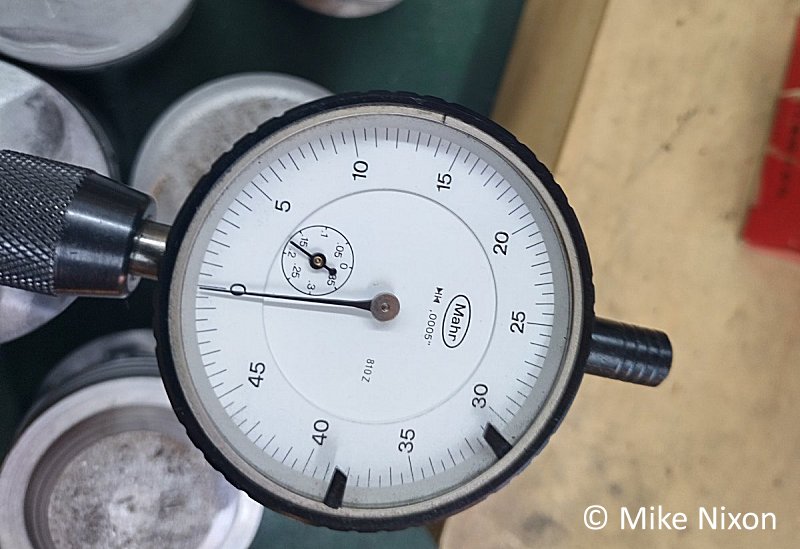

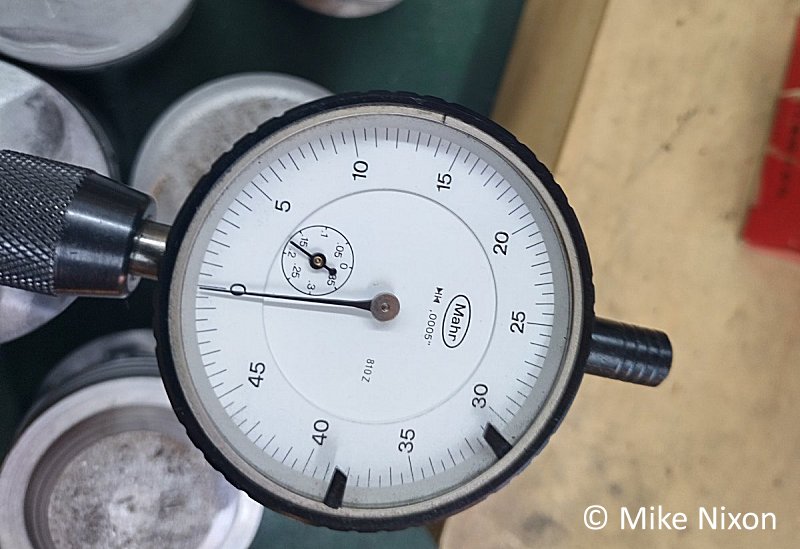

A dial bore gauge, an instrument for measuring cylinders, is prepared after determining piston size.

|

Once the piston and bore gauge are in sync, the gauge's dial is "zeroed".

|

|

|

This makes it a simple matter to track the size of the bored cylinder relative to the piston's size.

|

®

®