® ®

|

Thread repair |

|

|

|

|

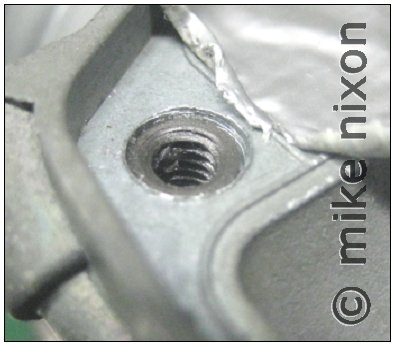

Isn't this a nice repair? I do a lot of these, especially on carburetors made of a high zinc aluminum alloy, such as this GL1000 carburetor. |

I favor the Timesert system. It's designed around a more machinist-like ethos than other systems. |

The Timesert thread insert is locked in place by broaching. That is, the final few threads are formed in place. It's very secure. |

|

|

|

|

|

|

|

|

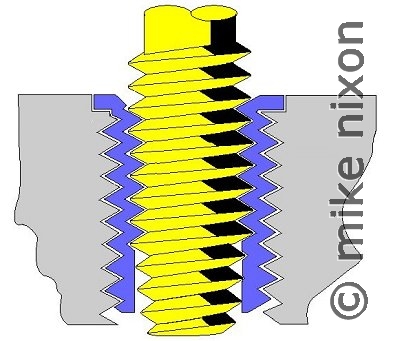

This promo pix from the company shows that unformed couple of threads. |

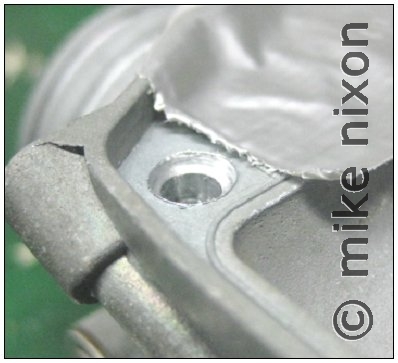

The carburetor is drilled, then counterbored as shown in this pix. |

The counterbore gives room for the insert's top lip to register to the carburetor. |

|

|

|

|

|

|

|

|

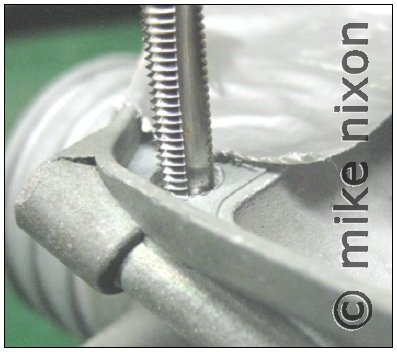

The hole is threaded for the insert. It's a special thread requiring the unique tap supplied in the kit. |

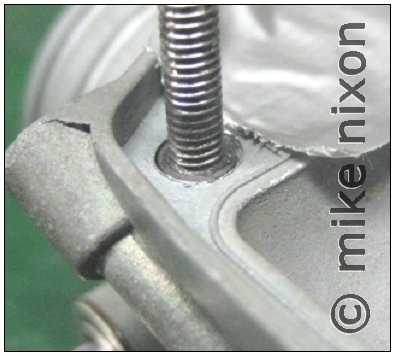

Then the insert is screwed in and the supplied broach forms the insert to the hole to lock it in place. |

It's the very best way to treat bad carburetor threads, |

|

|

|

|

|

|

|

|

This is the insert close up. It's threaded inside and out. Note the lip at the top also. |

Timeserts can actually be nested. This pix shows three Timeserts, one inside the other and then another. The part is a cylinder head. |

This carburetor had to have its idle jet hole repaired. A Timesert wasn't the best choice in this case. Instead, an aluminum plug was made, drilled and threaded for the jet. |

|

|

|

|

|

Last updated June 2025 Email me www.motorcycleproject.com My bio © 1996-2025 Mike Nixon |