® ®

|

Shucking the Shakes Revised |

|

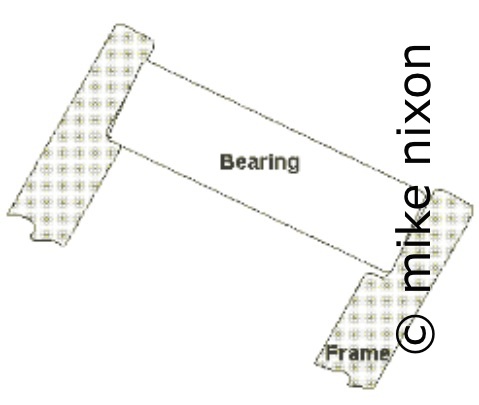

Hondas frequently develop a symptom of head shake when decelerating rapidly from 50+ mph. I like to call it a "deceleration wobble". The industry standard test is to get up to 50-60 mph and then release the throttle and hold the handlebars with only the tips of the fingers. As the bike slows the shimmy will ensue, becoming the most vigorous as the bike passes through the 35 mph range. Many things can cause oscillations like this, whether on acceleration or deceleration. Front tire wear is especially critical. But the decel specific thing is almost always caused by the steering bearings. Bearing looseness can do it, and this is virtually endemic in vintage Hondas because no one maintains their steering bearings. But along with that, the steering bearings often have become crooked, the races actually shifting in their recesses and becoming out of square with the steering stem. This is especially common on larger models, with the Goldwing over-represented in this. But smaller bikes do it also. Steering bearing misalignment sets up torque forces which manifest as attempts by the fork to correct itself, with the result, shimmy. And although just tightening the bearings can in many cases correct it, addressing bearing misalignment is usually more effective.

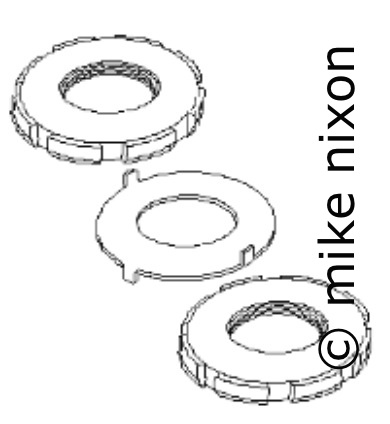

The following procedure is one circulated by American Honda's District Service Reps back in the day and actually hinted at in Honda Service Letter #126, a document explaining the need to fully seat replacement bearings. Though the technique originated for replacement bearings, it is valid for in-service steering bearings as well. Try to find Honda's special steering bearing nut socket, pt # 07916-3710100. Failing that, good reproductions are available and can be found by Googling the factory part number. You'll also want a torque wrench and a good quality tubular 0-10 lb. spring scale. A floor jack or something similar to lift the front of the motorcycle will be handy, too.

Follow your manual's instructions for removing the top clamp, or "bridge", so that the pair of special castlelated nuts becomes accessible. The upper one (if fitted, a few Honda models lack it) is a jam nut. Remove it and set it aside, along with the special washer. Jack the front end up off the floor, and feel the bearings as you turn the bars each side from center. If the bearings are notchy or the front end has a self-centering action, the bearings need to be replaced, no second-guessing here. After replacing them if necessary, continue. With the front end elevated, turn the fork to full right lock, and with the torque wrench and special socket, tighten the bearings to 40-50 ft-lbs. The fork will be very stiff. Don't panic. It's only temporary. Now turn the fork lock-to-lock, repeatedly, at least twenty times. You will probably notice something interesting: that ridiculously high tension will loosen up; the bearings will get looser, indicating that they have squared up and settled into the frame. In some cases, you won't be able to tell, but even if you don't, continue. Turn the fork to full left lock now and loosen the nut until it's just finger tight, then turn the fork to the right lock again and tighten the adjuster nut to 10 ft/lbs.

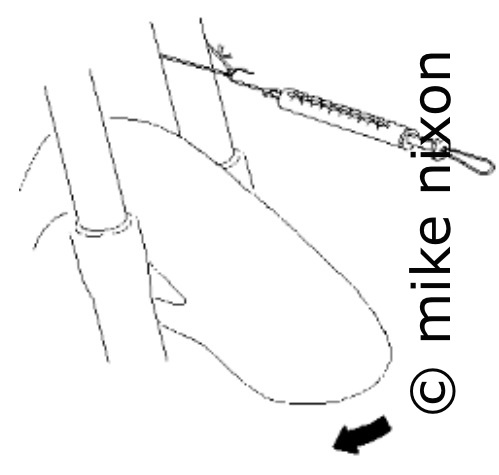

Attach your spring scale onto one fork tube, using a piece of shoestring or something similarly soft so as not to scratch the tube. With the fork assembly pointed straight ahead and the tire off the floor, slowly pull the spring scale until the tip of the fender arcs about one inch. Note the poundage. You're looking for a 5-7 lb. pull. The lower amount for most bikes, more for heavier machines and those with fairings or modifications such as low bars (because they increase the influence of the clutch cable). Tighten the tensioning nut as needed, a little at a time, and check with the spring scale.

After adjusting, drop the special washer back into place, and screw on the jam nut, and very gently jam it against the adjustment nut. Then bend the locktabs to keep the two interlocked. Reassemble the rest of the fork per the manual. If a test ride reveals that there is still a decel wobble, after raising the front end again, unbolt and raise the bridge half an inch and sneak a hook spanner in there to slightly add tension to the bearings. Repeat the spring scale test, and after buttoning everything up test ride again. If on the other hand the bike sways side to side like a rowboat when ridden, the bearings are too tight. Readjust, bolt everything up, and test ride as needed.

|

|

|

|

| The usual problem is bearing races that have become out of parallel. This is easily fixed. | Most vintage Hondas have these three pieces. Goldwings lack the jam nut and lockwasher. | The spring scale method is the best way to quantify bearing tension. |

|

Last updated January 2026 Email me www.motorcycleproject.com My bio © 1996-2026 Mike Nixon |