This is a subject that, like so many on powersports user forums, is virtually ignored. Yet it is vital. You cannot properly rebuild a 1970s Honda engine without doing what I describe here. Others may discount this technique or practice a variation of it. But no mechanic who serviced these bikes back in their day in a dealer retail environment will disparage it. This is the way it was done back then and continues to be necessary today.

Forget MLS (multilayer steel) head gaskets. The composite gasket Honda originally used is still the best for these vintage engines. And avoid Athena, Vesrah and NE substitutes. They are not up to the quality of the original. Of course, the original is very hard to find now, but knowledgeable mechanics know that Cometic, a small family business located in Ohio, faithfully reproduces the factory part. And don't listen to forum "experts" who advocate machining your cylinders or head in an attempt at improved sealing. There is no good reason to do that and several reasons not to. That is myth and the folks who perpetuate it reveal a very small amount of experience. They are not vintage Honda experts.

You do however want to coat that composite head gasket. Honda themselves started coating replacement head gaskets just a few years before the end of SOHC four production. Experienced mechanics did their own version of that and by then had been doing it for a long time. In every Honda dealership I worked at it was standard practice.

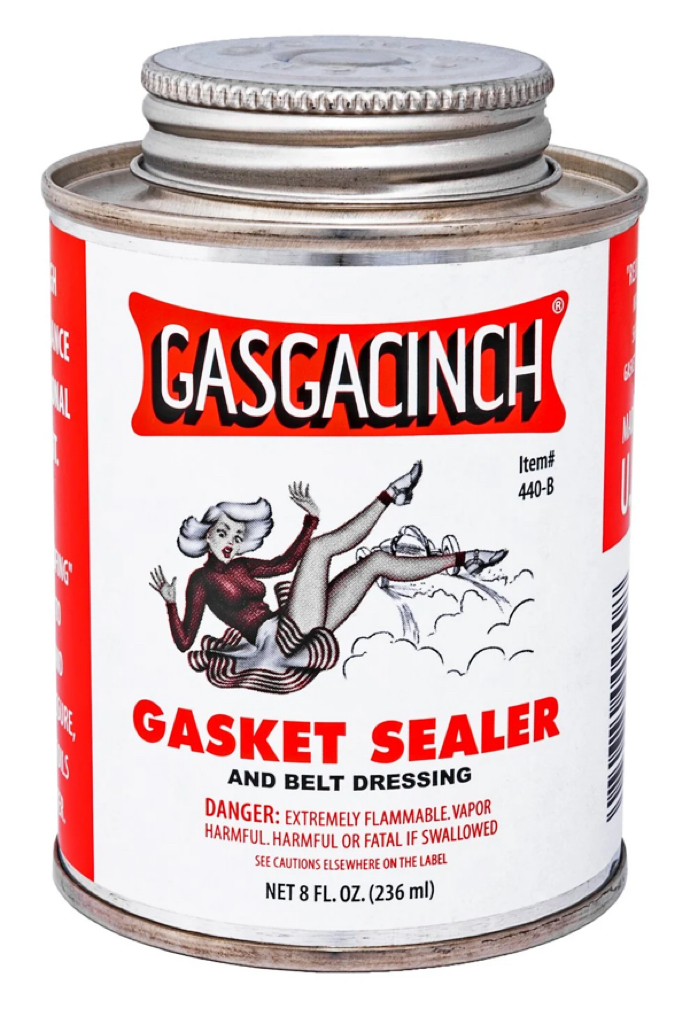

The sealer used varied, with some prefering Copper Coat. However, I and most of my collegues favored Gaskacinch, a gasket-specific rubber cement that has been around since the 1950s. After carefully preparing the gasket surfaces of both the cylinder and head assemblies, including stoning them and getting them meticulously clean, lightly coat both sides of the factory or Cometic composite head gasket with Gaskacinch. Let this dry for at least an hour before assembly.

Done this way, no machining is necessary, and normal factory head torquing is still used. Nor is it necessary to re-torque the top end. Honda has never promoted that. You'll find that the usual head gasket oil leak that seems to appear not long after engine assembly is absent and will stay absent for a good long while, in my experience many years.

®

®