® ®

|

The CB500/550 Head Gasket |

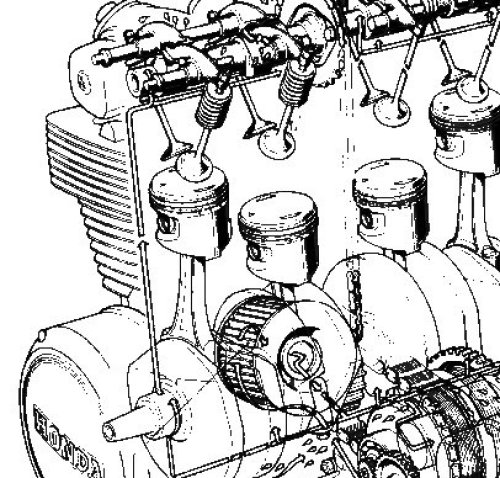

There is a lot of angst on sohc4.net about the tendancy for the 500/550 to leak oil at its head gasket. Of course, the 350 Four and 400F do as well, and the 750 too for that matter. All of these machines have one thing in common: the cam oiling circuit has its path through the cylinder block, which means it jets up through the head gasket. Honda stopped making its fours like this at the beginning of the 1980s.

It is a mystery to me how the forum can not be aware that pro Honda mechanics solved this virtually a lifetime ago. I spent dozens of years in Honda dealerships and I learned right away the technique, and have used it consistently ever since. And no, it is not milling the head. Nor does it involve the use of multi-layer steel (MLS) head gaskets. Milling is a foolish thing, and MLS gaskets a knee-jerk approach. Every Honda mechanic I ever knew did the same thing: we coated the factory composite head gasket on both sides with a product called Gaskacinch, essentially a rubber cement. The factory themselves shipped new head gaskets with a silicone coating during the final couple of years. This works. Countless customer experiences over decades back it up. And the fact that this escapes the public is a real mystery.

You must realize also that forums are not doing you any favors by promoting retorquing of the cylinder head. Does anyone really believe the factory expected or recommended this? Worse, sohc4.net insists you mill the head and/or use oversize oil passage o-rings. Part of the problem is no one seems to want to admit they are using inferior, non-OEM head gaskets. While the original gasket is hard to find, knowledgeable mechanics know that Cometic in Ohio makes a pretty good copy of the factory composite gasket. Get the Cometic gasket if you can't find factory, do the Gaskacinch thing, make sure the surfaces are spotless, and you will have long-term success.

A word about machining the head. The promotion of this idea is one more example of the 1940s cast-iron engine thinking that pervades vintage Honda forums. Why don't they realize, as career mechanics do, that 1970s Honda inline fours warp their heads normally? They are designed to work just fine warped. As such, no amount of milling is going to help. What does help is careful gasket surface prep and using sealer on the gasket. Moreover, milling the head introduces issues such as altered cam timing and reduced valve-to-piston clearance that you really don't want to have to deal with.

As for MLS head gaskets, it is hard to fault someone for wanting the latest technology. But stop and think about the context of the technology. Modern practice and vintage don't always mesh, and this is a perfect example of that. MLS gaskets began to be used in the production of motorcycle engines in the late 80s/early 90s. What you should know however is something else changed along with that: the engines began to be machined to a finer standard at the factory, and the engine castings were sturdier, more robust, in many examples with one-piece cylinder and crankcase. (So much more rigid and thus better sealing are these engines that some of them don't even use gaskets at the clutch cover.) The mirror finish on the CBR and ZX cylinder and head surfaces goes well with the MLS gasket. The far rougher surfaces on Honda sohc fours do not. Nor are the metal gaskets as forgiving of head warpage. The composite head gasket is for them a much better choice.

|

|

A little more... Vintage Honda head gaskets Email me www.motorcycleproject.com © 1996-2023 Mike Nixon |