® ®

|

CBX charging, part 3: The alternator drive coupling A nine-part series |

|

The Honda CBX1000 has a somewhat unusual alternator. To keep the engine width compact the alternator is mounted behind the cylinders on a separate shaft driven by the crankshaft through the primary chain. While not the only motorcycle having its alternator fitted in this way, it is not common either. |

|

What makes this alternator really unusual is the way it is driven, through a two-piece clutch arrangement located behind the unit. The clutch is there to take the torque peak off the driving part, the layshaft, a hollow, lightweight shaft that drives the ignition system on its other end. |

|

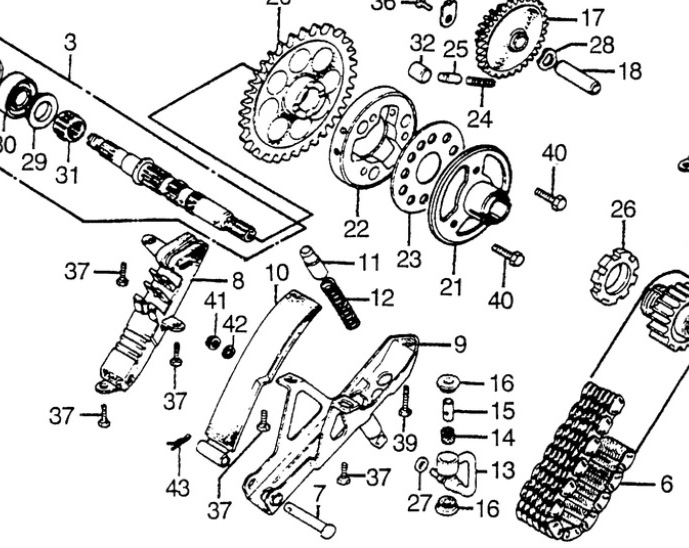

This is that primary shaft. The alternator is splined to the right hand end, the ignition is gear-driven from the left hand end, and the starter clutch and chain drive from the crankshaft go in the center. |

|

Another view. Same orientation as the picture above. The ignition goes on the left end. The primary chain from the crankshaft can be seen in the right foreground. The alternator would mount on the far right in this picture, actually out-of-frame. |

|

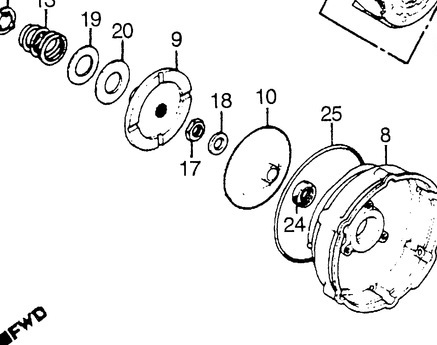

The clutch consists of two spring-loaded discs. One, the splined engine side disc, is shown here. The mating disc is bolted to the alternator itself, which is removed in this picture. |

|

Here's another view. Counting from the rear, you have a spring, two washers, and the drive plate. Then the nut and washer that fixes the driven plate, and the driven plate itself, its oil seal, the housing o-ring, and finally the housing in the foreground. |

|

This system develops an issue pretty much immediately. See the magazine article. The symptom can take two audible forms. It can be either a valve-like high-frequency rattle / rolling tick at very low speeds with large throttle opening (coming out of a slow corner). Or it may appear when decelerating from high rpm, when it is usually described as a "clack." In addition, the sound is often accompanied by a lower average onboard voltmeter reading. |

|

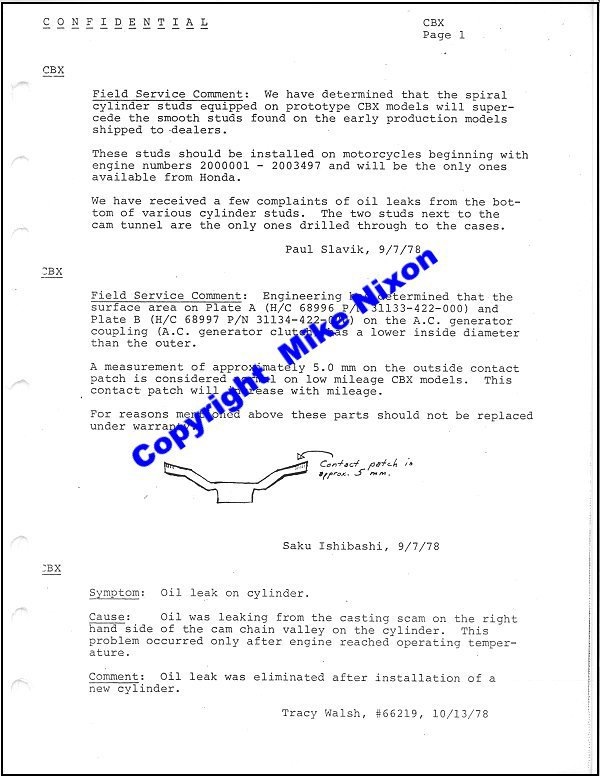

The fault in the system lies in a design error, Honda admitted in an internally-circulated memo (I worked for the corporate office at the time). This memo reveals the problem and suggests no remedial action be taken on the part of the company. |

|

Here is the problem demonstrated with a straightedge. The engine side disc is manufactured cupped. Thank you Nils Menten! Click on the picture to enlarge. What this means is two things. First, as is apparent here and as the memo describes, the two plates touch each other only at their edges (5mm worth, according to the memo). This is a bad situation. It is not enough contact to carry the load. Further, it means, again as the memo suggests, that the discs are predisposed to wear rapidly. Tear themselves up, actually. |

|

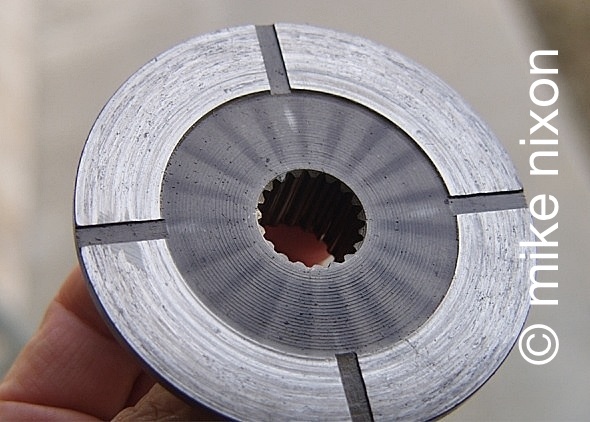

This is an example of the result. This engine side disc has only 18,000 miles on it. The whole surface is galled and torn. The disc set this disc came from was probably slipping more or less full time. This disc was later successfully rehabilitated, there being no deep gouges. We'll look at how it was done. |

|

And here is one from a school bike, one with just 12 miles. You can still see the as-manufactured cross-hatch on the surface, but also, the gouging that has already begun. In 12 miles. So you see, the damage starts immediately. |

|

Here's another example, this one an alternator side disc with a lot more miles than either of the previous ones, but showing the same wear pattern as the last one. There's that trench that has been ground into the disc, as metal tore then balled up and skated. The gouging is so deep that to remove it would unfortunately thin the disc excessively. This disc set had to be replaced. |

|

Coupling disc rehabilitation is a waste of time. Note also that replacement discs from Honda are no longer available. I prefer to just shim the assembly until the discs can't spin. At all. Shim until the discs will not separate. This is the 14v solution. If everything else in the charging system is good, this one thing will raise the onboard voltmeter to just shy of 14 volts. This may seem crude but it is no more than what the Denso conversion does.

I have written an article on the Supersport Shed disc mod. I don't recommend it.

|

|

Last updated June 2025 Email me www.motorcycleproject.com My bio © 1996-2025 Mike Nixon |