® ®

|

Cam Contemplations #1: Camshaft Basics A six-part series |

|

Camshaft. An exotic word, even in this day of plastic-wrapped, multiple computer equipped motorcycles. And few words have stirred the soul of the motorcycle gearhead as much as this one. Perhaps as a consequence, folks tend to think they know more about cams than they actually do. Did you know for example that Honda once made cams with angled lobes that made the valves rotate and thus clean themselves of carbon? A good idea but they had to stop because customers complained of knocking noises in the cylinder head, caused by the lateral thrust the angles created. Honda actually put aluminum cams in some of their stationary engines, many modern cams have pop-up pins in their lobes to reduce compression during starting, and some manufacturers change their cams's timing relative to the crankshaft while the engine is running to broaden its torque curve, i.e., variable cam timing--early intake opening for low rpm, late for high rpm. Cams have changed a lot in the past fifty years, with the lift-to-diameter ratio one of the most significant changes. More about that one later.

Air cycles

The stock vs. the performance cam

However, the manufacturer plays to a very different set of rules than does the engine modifier. In a four-stroke engine having a warranty and the widest possible user target, there is not much of this wave tuning going on. The stock camshaft is so mild that it restricts these effects. Honda's 1970s SOHC fours open their valves less than a quarter inch. The pulses, though there, bounce ineffectively off of closed valves. The intake and exhaust tracts' pressures and suctions go unrealized. The stock engine also depends heavily on intake airspeed. A hot-rodded engine's extended valve timing reduces intake air velocity and density. Engine power may be increased, but that increase will be focused around a particular rpm range, and not spread as broadly over the rpm as before, due mostly to the slowed air. Sluggish intake air also reduces combustion efficiency due to reduced fuel and air homogenation. Combustion, and thus torque, suffer. Manufacturers know better than to tune an engine this way.

|

|

|

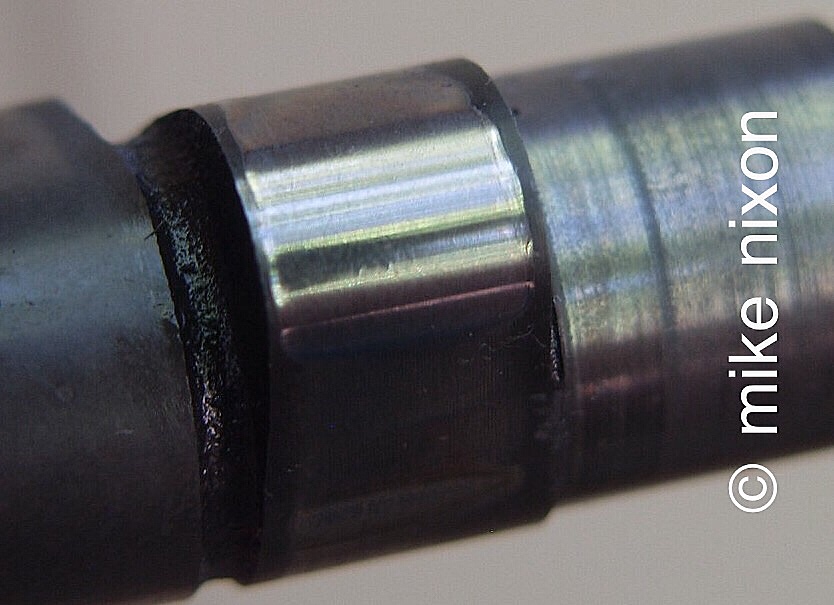

Pretty astonishing, isn't it? However, this is not damage and not unusual wear in a 70s Honda four cam. It's very common. The cams are soft and the rocker arms hard via chrome plating. SOHC four cams wear very quickly. |

|

I'll have more to say about cam problems later. However, this is not about problems. Above is a cam from a 1974 Honda CB350F, a smallish four-cylinder model that is one of the several single overhead cam (SOHC) 70s Hondas that are now very collectible. We're looking at one of the cam's lobes, and what is visible is a surprising amount of wear on this cam. This is not damage. It is not catastrophic. No signs of excessive friction are visible. The engine was not run low on oil and there weren't any oil related problems. In fact, the engine is at this moment completely apart and there is no wear anywhere else. What gives? This wear is more than most people would expect in just 4900 miles. That's right, 4900. And it's normal. It is not excessive.

The fact is, camshafts in a good many engines from cars to motorcycles and even to piston-engined aircraft wear like this. Hondas can be observed to wear their cams at a rate between 0.001" to 0.003" per thousand miles, as shown in this example. Industry insiders know well that cams are not made the way people think they are. They're not extremely hard. They're not even moderately hard. With very few exceptions, a cam from any Honda SOHC four can easily be drilled with a standard HSS drill bit, the kind you can pick up at the bargain table at the hardware store. Yup. And when they see the kind of chips that fly out of that drilled hole, experienced machinists recognize them instantly. Cast iron! Yup. Most cams are cast iron or cast steel. And very soft. Below Rockwell 52 in fact, for you metallurgists.

So what? Well, this explains something. It means that these vintage bikes with 20,000 to 40,000 miles have some significant wear on their cams. Enough to make the engines perform below their potential, demonstrably, more due to valve timing retardation than anything. In fact, the thing I see most often signalling this wear is valve timing quite a bit off from spec. Naturally, the typical 5 to 10 degree discrepancy can also be attributed to cam chain wear, but not in extremely low-mileage engines like this 350F. This in turn means that in many cases folks who swap in aftermarket cams are very probably seeing gains not from the supposed advantages of said products but rather from the correction of the stock systems' wear or misadjustment. A new part brings the below-standard function to the standard, normal efficiency of a new unworn part. The same thing happens with aftermarket ignition systems. A stock ignition that was never properly serviced is replaced with an electronic system and the improvement is ascribed to the latter being a better system, when in reality it is not. It's simply that something was finally done to help the poor ailing motorcycle! It's called "unintended consequences". Big bore kits, aftermarket carburetors, racing air filters--all of them deliver improvements that are due much much more to overcoming lack of maintenance than to the supposed superiority of these parts.

One of the biggest secrets in vintage Honda engine rebuilding is how camshafts welded up and reground to factory specs--they are now widely available (and the factory replacements long-gone)--are now offered by the big-name cam makers Megacycle and Webcam. Don't overlook this benefit. Replacing your 10,000-mile cam with another just like it isn't the answer. It's worn as much or more than yours. A newly remade cam to stock specs really is a wonder.

|

|

Last updated June 2025 Email me www.motorcycleproject.com My bio © 1996-2025 Mike Nixon |