® ®

|

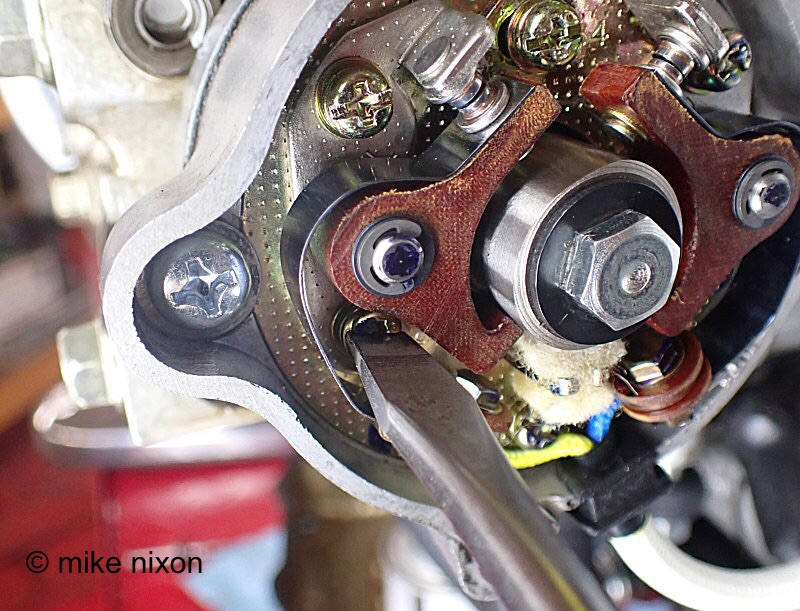

Fourteen anomalies of the Honda GL1000 ignition that make it one of the most difficult to time of all vintage Honda streetbikes. |

|

The GL1000 is not just an iconic bike, it is a time capsule into another era, and a very pleasant ride. One of my favorite vintage Hondas, it is relatively simple to service, except for one area that is challenging and is rarely done right. Here are fourteen hints on adjusting the GL1000 ignition. 1. The GL1000 ignition is driven by a toothed rubber belt. This means its timing is dependent on good belt maintenance, i.e. tensioning. Sloppiness here results in sloppiness at the ignition. The belt must be carefully tensioned first thing in any tuning scenario. And that means much more than simply loosening the lockbolt and letting the spring do it all. Uh uh. 2. While the belt drives the cam, at the same time the engine’s valve springs oppose that drive, in a way that produces intermittent pulses. The result is no matter how well the rubber belt is tensioned, every 360 degree rotation of the crankshaft (180 degrees rotation of the camshaft) applies varying valve spring forces to the cam and belt arrangement, resulting in changes in cam timing, thus changes in ignition timing. It's unavoidable. 3. The situation just described is further aggravated by a very loose fit (more than 0.005") of the camshaft in its bearings that allows the cam to rock in response to valve spring and drive belt forces, and the ignition along with it. You see a trend developing here? 4. The ignition is mounted on a snout made into the left camshaft. This projection is not always straight, typically exhibiting some 0.003” indicated runnout. This too affects ignition timing. 5. The ignition’s advance mechanism has two defects. First, the advancer cam’s two lobes are not ground 180 degrees apart. Second, one of the lobes is larger than the other. These things also create timing irregularities, about which more is said later. 6. The points backing plate is a fairly loose fit in the left cylinder head casting. Each time it is rotated to effect a timing adjustment, the plate moves laterally as well as rotationally. The lateral movement changes the carefully adjusted point gap, which in turn also changes the timing. A situation very much like the SOHC inline four. 7. The sub-plate on the right side that adjusts the timing of the two rear cylinders does not adjust concentric with the backing plate. This means that adjusting the timing of the right side points necessarily changes their gap also, which of course makes timing changes greater than expected. Which means the timing has to be corrected an additional time, then the gap yet again. 8. Although the original Hitachi and TEC branded points assemblies were very high quality, aftermarket substitutes and even the latest TEC branded factory replacements are fair to very poor, resulting in reduced precision, reliability and durability. Avoid them. 9. The backsides of these same inferior points and current are not flat, so that when their screws are tightened, gap and timing both change, starting the whole timing-then-gap-then-timing cycle referred to above all over again. The original points of the 1970s did not do this. 10. Honda designed into the points system pry points for adjusting the point gap. These pry points are meant to be facilitated with a screwdriver, but they are difficult to use. 11. There are Taiwanese hold-down screws on these point assemblies. They look like they are a combination of flat blade and Phillips but they are actually neither. It’s best to use only a flat blade screwdriver on them. Using a Phillips screwdriver will tear up these delicate screws’ heads. Virtually every GL1000 I have serviced has had torn up screws. 12. Many of these problems would be relatively minor if not for the GL1000’s waste spark ignition system. The waste spark ignition method means that the advance mechanism’s two lobes alternately operate the same points set. Combined with the above issues, the result is timing that is significantly different each time one lobe passes the same set of points versus the other lobe. Every 360 crankshaft degrees, the timing is unique and can virtually never be identical. Essentially, the ignition wobbles. 13. This last issue produces what the industry calls a “ghost” effect when strobe timing the ignition. For this reason, strobe timing is not the preferred timing method, and even the official manual communicates this. Though it addresses both methods, it gives a lot more focus to the static method. Painstaking static timing is virtually mandatory as it is the only way the wobbling timing can successfully be addressed. Conversations with the factory back in the 70s confirmed their awareness of the frequency of this method in the field, as well as their own preference for it. 14. Fitting a Dyna or other electronic ignition, while a good alternative on a handful of fronts, does not do away with all of these issues, though it does eliminate those associated with the advance mechanism’s point cam, the part that is removed when fitting a Dyna. However, that leaves more than half of the problems enumerated here. Plus, the Dyna introduces its own set of issues. |

|

Related reading on this site: The GL1000 problem |

|

How-to booklet: Timing the GL1000 Ignition |

|

Last updated February 2026 Email me www.motorcycleproject.com My bio © 1996-2026 Mike Nixon |