® ®

|

Cylinders Done Right |

|

Unfortunately, there is a kind of alternate universe when it comes to these all too important areas of an engine. The serendipity with which most folks approach cylinder heads and cylinders astonishes me. I've often said that instead of porting and big bores, which indeed have their place, spend your resources on getting the cylinders and head to work right, to factory spec--which they aten't on a fifty year old machine, you can count on that. I have proven to customers that meticulous attention to standard specification yields benefits rivaling and sometimes excelling that of the more sensational exercises of big cylinder bores and cylinder head porting. Standard performance done right trumps high performance done sloppily every time. Or to say it another way, what is often mistakenly thought mundane and unglamorous, cylinder and head rebuild work holds far more performance potential than many realize.

The Automotive/Performance Influence

Ring End Gaps

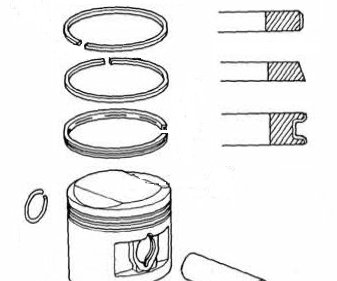

Piston rings traditionally have had faces that are not square but slightly tapered so they will scrape oil downward away from the combustion chamber. Because of this, the best rings, including all OEM, bear a mark on their upper surface as an aid to proper installation. Many of the recent crop of Chinese rings now flooding the market have no marking, leading some to assume these rings are not tapered and thus require no special installation. Unfortunately, good mechanics are finding that some of these rings are indeed tapered, despite not being marked. Watch out for this.

Piston Availability

Ring Availability

That is a stock Honda piston on the left, aftermarket kit piston on the right. The two are joined by a piston pin for alignment purposes. You're looking at 1mm difference in deck height. Not good. This 3mm overbore piston results in stock cylinder compression. The loss is in the deck.

|

|

Take a look at the factory Honda specifications for the following models. A special note. Honda has fairly consistently made you work at finding their engines' recommended piston-to-cylinder clearances. Only a few official manuals for vintage models give the clearance as a stand-alone spec. In most cases you must determinde piston clearance by doing the math on the official as-manufactured cylinder and piston dimensions. |

|

CB125 Single (pg 16) |

CB175 Twin (pg 29) |

CB350 Twin (pg 40) |

CB350F SOHC Four (pg 76) |

CB400F SOHC Four (pg 106) |

|

Piston 55.97~55.99 |

Piston 51.96~51.98 |

Piston 63.97~63.99 |

Piston 46.47~46.99 |

Piston 50.97~50.99 |

|

Cylinder 56.00~56.01 |

Cylinder 52.00~52.01 |

Cylinder 64.01~64.02 |

Cylinder 47.00~47.01 |

Cylinder 51.00~51.01 |

|

Clearance 0.01~0.04 |

Clearance 0.02~0.05 |

Clearance 0.02~0.05 |

Clearance 0.01~0.04 |

Clearance 0.01~0.04 |

|

Clearance inches 0.00039~0.0016 |

Clearance inches 0.0008~0.0019 |

Clearance inches 0.0008~0.0019 |

Clear inches 0.0004~0.0015 |

Clear inches 0.0004~0.0015 |

|

Clearance average 0.0010 |

Clearance average 0.0014 |

Clearance average 0.0014 |

Clearance average 0.0009 |

Clearance average 0.0009 |

|

Clearance given NA |

Clearance given NA |

Clearance given NA |

Clearance given NA |

Clearance given NA |

|

Clearance service limit 0.01181 |

Clearance service limit NA |

Clearance service limit 0.00781 |

Clearance svc limit 0.00981 |

Clearance svc limit 0.00981 |

|

Ring end gap top 0.0059~0.0138 |

Ring end gap top NA |

Ring end gap top NA |

Ring end gap top 0.004~0.012 |

Ring end gap top 0.0059~0.0138 |

|

Ring end gap 2nd 0.0059~0.0138 |

Ring end gap 2nd NA |

Ring end gap 2nd NA |

Ring end gap 2nd 0.004~0.012 |

Ring end gap 2nd 0.0059~0.0138 |

|

Ring end gap oil 0.0059~0.0158 |

Ring end gap all 0.006~0.016 |

Ring end gap all 0.008~0.016 |

Ring end gap oil 0.010~0.0352 |

Ring end gap oil 0.0079~0.0197 |

|

End gap svc limit top NA |

End gap svc limit top NA |

End gap svc limit top NA |

End gap svc limit top 0.0276 |

End gap svc limit top 0.0276 |

|

End gap svc limit 2nd NA |

End gap svc limit 2nd NA |

End gap svc limit 2nd NA |

End gap svc limit 2nd 0.0276 |

End gap svc limit 2nd 0.0276 |

|

End gap svc limit all 0.0197 |

End gap svc limit all 0.0315" |

End gap svc limit all 0.0315" |

End gap svc limit oil 0.0276 |

Ring end gap svc limit all 0.035 |

|

CB500 SOHC Four (pg 139) |

CB550 SOHC Four (pg 141) |

CB750 SOHC Four (pg 23) |

CB750 DOHC Four (pg 7-1) |

CB900 DOHC Four (pg 7-1) |

|

Piston 55.97~55.99 |

Piston 58.47~58.49 |

Piston 60.965~60.985 |

Piston 61.95~61.98 |

Piston 64.46~64.49 |

|

Cylinder 56.00~56.01 |

Cylinder 58.50~58.51 |

Cylinder 61.01~61.02 |

Cylinder NA |

Cylinder 64.50~64.51 |

|

Clearance 0.01~0.04 |

Clearance 0.01~0.04 |

Clearance 0.025~0.055 |

Clearance see 900 spec |

Clearance 0.01~0.05 |

|

Clear inches 0.0004~0.0015 |

Clear inches 0.0004~0.0015 |

Clear inches 0.001~0.002 |

Clear inches see 900 spec |

Clear inches 0.0004~0.0019 |

|

Clearance average 0.0009 |

Clearance average 0.0009 |

Clearance average 0.0015 |

Clearance average see 900 spec |

Clearance average 0.0012 |

|

Clearance given NA |

Clearance given NA |

Clearance given NA |

Clearance given NA |

Clearance given 0.0004~0.0020 |

|

Clearance svc limit 0.00981 |

Clearance svc limit 0.00981 |

Clearance svc limit 0.00981 |

Clearance svc limit 0.004 |

Clearance svc limit 0.004 |

|

Ring end gap top 0.005~0.013 |

Ring end gap top 0.005~0.013 |

Ring end gap top 0.007~0.016 |

Ring end gap top 0.004~0.012 |

Ring end gap top 0.006~0.012 |

|

Ring end gap 2nd 0.005~0.013 |

Ring end gap 2nd 0.005~0.013 |

Ring end gap 2nd 0.007~0.016 |

Ring end gap 2nd 0.004~0.012 |

Ring end gap 2nd 0.006~0.012 |

|

Ring end gap oil 0.010~0.0352 |

Ring end gap oil 0.010~0.035 |

Ring end gap oil 0.010~0.0352 |

Ring end gap oil 0.012~0.035 |

Ring end gap oil 0.012~0.035 |

|

End gap svc limit top NA |

End gap svc limit top 0.027 |

End gap svc limit top NA |

End gap svc limit top 0.020 |

End gap svc limit top 0.020 |

|

End gap svc limit 2nd NA |

End gap svc limit 2nd 0.027 |

End gap svc limit 2nd NA |

End gap svc limit 2nd 0.020 |

End gap svc limit 2nd 0.020 |

|

Ring end gap svc limit all 0.027 |

End gap svc limit oil 0.043 |

Ring end gap svc limit all 0.028 |

End gap svc limit oil 0.043 |

End gap svc limit oil 0.040 |

|

CB1100 DOHC Four (pg 10-1) |

CBX1000 (79~82 pg 7-1) |

VF750C/S 82 (pgs 12-1, 12-5, 25-22) |

GL1000 (pg 6-2) |

CBR600 F4 (pg 1-8) |

|

Piston 69.970~69.980 |

Piston 64.47~64.49 |

Piston 69.960~69.990 |

Piston 71.945~71.970 |

Piston 66.965~66.985 |

|

Cylinder NA |

Cylinder NA |

Cylinder NA |

Cylinder 72.000~72.150 |

Cylinder 67.000~67.015 |

|

Clearance see 900 spec |

Clearance see 900 spec |

Clearance NA |

Clearance 0.030~0.105 |

Clearance 0.015~0.050 |

|

Clearance inches NA see 900 spec |

Clearance inches NA see 900 spec |

Clearance inches NA |

Clearance inches 0.001~0.004 |

Clearance inches 0.0006~0.0019 |

|

Clearance average see 900 spec |

Clearance average see 900 spec |

Clearance average 0.0012 |

Clearance average 0.0025 |

Clearancce average 0.0013 |

|

Clearance given NA |

Clearance given NA |

Clearance given 0.0004~0.00202 |

Clearance given 0.0012~0.0027 |

Clearance given 0.0006~0.0020 |

|

Clearance svc limit 0.0039 |

Clearance svc limit 0.004 |

Clearance svc limit 0.0042 |

Clearance svc limit 0.006 |

Clearance service limit 0.002 |

|

Ring end gap top 0.0059~0.0138 |

Ring end gap top 0.006~0.012 |

Ring end gap top 0.004~0.012 |

Ring end gap top 0.010~0.016 |

Ring end gap top 0.004~0.008 |

|

Ring end gap 2nd 0.0059~0.0139 |

Ring end gap 2nd 0.006~0.012 |

Ring end gap 2nd 0.004~0.012 |

Ring end gap 2nd 0.010~0.016 |

Ring end gap 2nd 0.007~0.012 |

|

Ring end gap oil 0.018~0.035 |

Ring end gap oil 0.012~0.035 |

Ring end gap oil 0.012~0.035 |

Ring end gap oil 0.008~0.035 |

Ring end gap oil 0.010~0.030 |

|

End gap svc limit top 0.020 |

End gap svc limit top 0.020 |

End gap svc limit top 0.020 |

End gap svc limit top 0.027 |

End gap svc limit top 0.020 |

|

End gap svc limit 2nd 0.020 |

End gap svc limit 2nd 0.020 |

End gap svc limit 2nd 0.020 |

End gap svc limit 2nd 0.027 |

End gap svc limit 2nd 0.020 |

|

End gap svc limit oil 0.043 |

End gap svc limit oil 0.040 |

End gap svc limit oil 0.040 |

End gap svc limit oil 0.043 |

End gap svc limit oil 0.040 |

|

First three measurements only metric, the rest are Imperial |

1 Incredible! |

2 Corrected from obvious typo |

© Mike Nixon, The Motorcycle Project |