|

|

One of the better reasonably-priced alternatives to the shop-grade exhaust gas analyzers, this Bridge two-gas unit is accurate and easy to use.

|

Emissions Gases

There are five emissions gases. Some are emitted from the exhaust, some are evaporated from the vehicle. Here is a summary of the exhaust gases as a technician deals with them.

Oxygen

Oxygen (O2) is not a regulated gas. However, it is useful for diagnostic purposes. At sea level the atmosphere contains 20~21% oxygen. Normal amounts in engine exhaust are 2~5%. Knowing the expected amount in the exhaust can help you diagnose engine problems.

Carbon Dioxide

During the combustion process, the oxygen in the air combines with the carbon in the fuel. If the proportions of each are correct, the exhaust contains one part carbon to two parts oxygen. This perfect combination results in a gas called carbon dioxide (CO2). In terms of combustion efficiency, CO2 is a "good" gas. The more efficient the combustion, the more CO2 is found in the engine's exhaust. The usual amount is 12~14%. Low CO2 indicates that the air/fuel mixture is either too rich or too lean.

Carbon Monoxide

The proportions of air and fuel that are combusted are however not always ideal. A typical problem is too little oxygen. The ratio of the two gases is then one part carbon to only one part oxygen. The result is carbon monoxide (CO). The accepted concentrations of CO in 1970s through early 1990s four-stroke powersports vehicle exhaust ranged between 1.5% and 4.5%. Because CO results only from a lack of oxygen, it is a good indicator of a slightly-rich air/fuel mixture. CO is a dangerous gas to air-breathing creatures. It displaces oxygen in the bloodstream, leading to slow suffocation. CO is also colorless and odorless, which makes it all the more lethal. The technician who is overcome with carbon monoxide feels tired at first, then confused. Loss of consciousness results. Enclosed working areas must include forced air ventilation to prevent CO poisoning.

Hydrocarbons

Some air/fuel mixture always escapes into the exhaust system. Gasoline is a hydrocarbon. The tiny bit of fuel that is blown into the exhaust system is therefore known as hydrocarbons (HC). While some is normal, too much HC is a tip-off to mechanical or electrical problems that affect combustion. Hydrocarbons are measured in the same way environmental pollutants are, in parts per million (ppm). Accepted amounts of HC in the exhaust for 1970s through early 1990s four-stroke powersports vehicles ranges between 150~250 ppm for later models and as much as 400~800 ppm for the older stuff. However, the exhaust system isn't the only place HC is emitted. Fuel vapors waft into the air from several points on the vehicle. This happens even when the engine isn't running, which is why originally California and New York model powersports engines and increasingly all engines have contolled venting systems. HC is a controlled gas because it combines with other gases in our air to create smog.

Oxides of Nitrogen

Oxides of nitro�gen (NOx) is another pollutant produced by the engine. NOx is created by abnormally high combustion temperatures. An example is when detonation is present. Incorrect ignition timing or excessive mixture leanness also result in this gas. Normal combustion produces very little NOx. NOx is a human health hazard because it combines with HC and reacts with sun�light to create smog.

The Exhaust Gas Analyzer

The EGA is a very useful tool for maintenance service, as well as for emissions testing. There is no better way to gauge carburetor adjustments than with the EGA. Many shops use the EGA routinely during every vehicle maintenance service.

Vehicle Diagnostics

The EGA isn't just a tune-up tool however. The machine is to vehicle maintenance what the multimeter is to electrical diagnostics. It is just as versatile. The EGA is used to diagnose engine performance (driveability) problems that would otherwise take hours to resolve. The following paragraphs will explain this in more detail.

The Two-Gas EGA System

Older EGA machines measure just two gases, CO and HC. These two gases provide a wealth of diagnostic information. Following is a summary of what each means.

CO

As already explained, a high CO reading indicates richness. In other words, too little oxygen. On the fuel side of the mixture, look for rich idle mixture settings, high float levels, or leaking float valves. Also, the needle jets may be worn, or the choke plungers may be leaking. If a fuel-injected engine, the fuel pressure may be too high. On the air side, the air filter may be dirty or the carburetor's air bleeds restricted.

HC

Excessive HC readings are a bit trickier. High HC always indicates combustion breakdown, because it literally means some of the fuel is getting from the fuel tank to the exhaust pipe without being burned. However, from there it gets tricky because there are four possible causal areas. First, the most likely one is an electrical misfire. There could be worn spark plugs, arcing plug wires, or other ignition system problems. Second, high HC may also be due to a fuel misfire, that is, severely incorrect air/fuel mixture resulting in misfire. This could be caused by extreme richness due to a torn petcock vacuum diaphragm, or extreme leanness due to a vacuum leak. Third, the high HC reading may be due to mechanical causes. This would include valves and piston rings, a leaking cylinder head gasket, and similar faults. Finally, high HC readings can result from the presence of fuel in the engine oil. Powersports vehicles often overflow fuel from their carburetors into the crankcase. The crankcase oil then has a high HC content. Crankcase vapor control systems, remember, connect the crankcase to the intake. Thus the air/fuel mixture is immediately affected, and the richness shows up in the exhaust.

Two-Gas Troubleshooting

Although high HC readings can be tricky to diagnose, the key to finding the cause of a high HC reading is in viewing the CO. In fact, any time EGA diagnostics is performed, the rule is to compare one gas with another to get the total picture.

Electrical Misfire

An electrical misfire is indicated when the HC is high and the CO is normal. This is especially true if the HC jumps upward periodically, with the CO dipping correspondingly. This points toward intermittent ignition.

Fuel Misfire

A high HC reading accompanied by a low CO reading may be either air/fuel mixture related or ignition related. That is, the ignition could be performing far below capacity, rather than intermittently as before. This would reduce the CO. Determine whether the problem is fuel or ignition by very slightly applying the choke, if the machine has carburetors. Alternately, tape up part of the air filter on EFI bikes. If the CO increases, the ignition system is okay. It can support combustion. The fuel system is at fault. That is, there is a lean misfire.

Mechanical Causes

A high HC reading accompanied by a high CO reading is caused by either mechanical or fuel system faults. The ignition system is okay because the high CO verifies that it is functioning normally. Simply perform a compression check on the engine to verify a mechanical cause for the high HC.

Fuel in the Oil

Verify fuel in the oil by measuring the HC in the exhaust the usual way, then simply unplug the crankcase breather and measure it again. There should be no difference. Double-check by shutting off the engine and inserting the EGA probe into the crankcase or oil tank. Do not start the engine and do not get oil on the EGA probe. There should be no reading. If there is a reading, there is fuel in the crankcase. When a car fails the HC test, it is pretty well known that simply changing the engine oil can make it pass.

Cruise Check

Because the engine is designed to work best at high rpm, its combustion should be more efficient as rpm are increased. Both HC and CO readings should drop somewhat under the idle reading, most often to levels approximating half those at idle. With a warm engine, rev to half throttle. Hold for 30 seconds. If the CO increases, the cruise part of the fuel system is too rich. Check for a dirty air filter, or worn or incorrect carburetor parts or adjustments. Also verify correct fuel pressure on EFI vehicles. If the CO goes down like it should but the HC does not, treat this as a misfire. Do the enrichment test to determine whether the fuel or ignition system is the cause.

The Four-Gas EGA System

Vehicles with catalytic converters are difficult to diagnose with two-gas units. One solution is to insert the EGA probe into the exhaust system between the engine and the catalyst. It's also necessary in most cases to temporarily defeat air injection and other emissions systems. The best solution however is to use a four-gas unit. Four-gas EGAs aren't however very common in powersports shops.

The Four-Gas Method

The four-gas EGA measures CO2 and O2 in addition to CO and HC. Comparing all four of these gases with each other is the key to modern EGA diagnostics. It's also the best way to diagnose catalytic converter equipped vehicles. The four-gas method compensates for the masking effect the catalyst has on CO and HC.

Four-Gas Troubleshooting

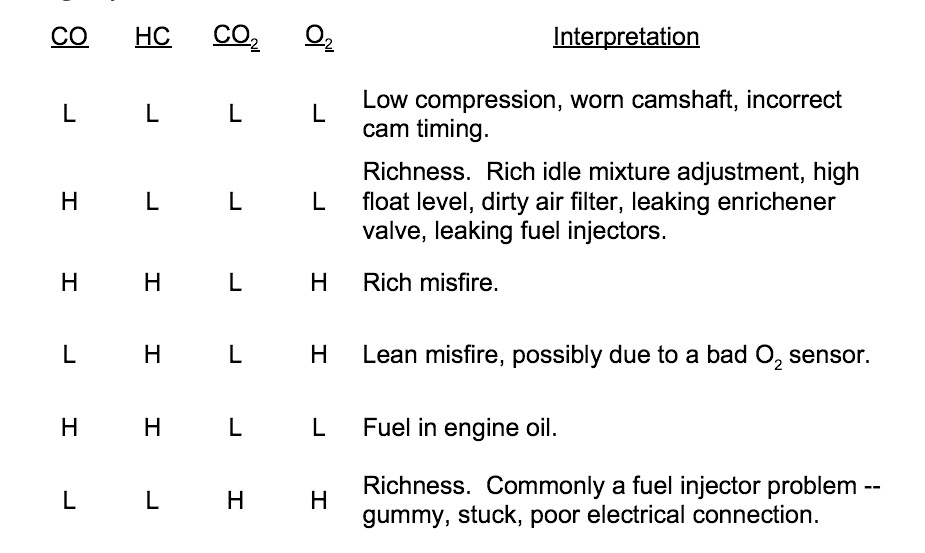

The key to four-gas troubleshooting is found in two relationships. The first relationship is the one between CO and O2. These gases should be nearly equal to each other. They are also inversely proportional -- when one goes up the other goes down, and visa-versa. If CO is high, O2 will be low, indicating richness. Conversely, if O2 is high, CO will be low, indicating leanness. The second critical relationship is the one between CO and CO2. Excessive CO2 by itself indicates either richness or leanness, but doesn't tell us which. A look at the CO level then indicates which it is -- richness or leanness. Just as in two-gas diagnostics, low CO is leanness, high CO indicates richness. Refer to the following table for other combinations. (L = low, H = high.)

Carburetor Adjustment

Warming up the engine before carburetor adjustments are made is extremely important. Adjustments made to a cold engine will be too rich when the engine is warm. Don't however let the engine get too hot. An adjustment made on an overheated engine will be too lean when the engine is at normal temperature. Also warm up and if necessary calibrate the EGA. Insert the EGA probe at least 18" into the exhaust system. Otherwise the readings will be diluted by outside air which enters the exhaust system between exhaust pulses.

Adjust to the CO

Adjust the idle mixture to the correct CO reading. Never mind the HC. It will take care of itself as the CO is adjusted. As long as the HC is below 400 ppm in late model vehicles, or 800 ppm in older ones, it's okay. Some manufacturers specify EGA settings, but many others do not. Late model, electronically-controlled engines are "happiest" at 1~2% CO. A few thrive as lean as 0.5%. However, engines a few years older "like" their idle mixture screws adjusted to between 2.5~3.5% CO, some even as high as 4.0~4.5%.