® ®

|

common-motor.com 450 engine video issues |

|

|

|

Lubricating the main bearing rollers. |

Good one! To their credit. |

|

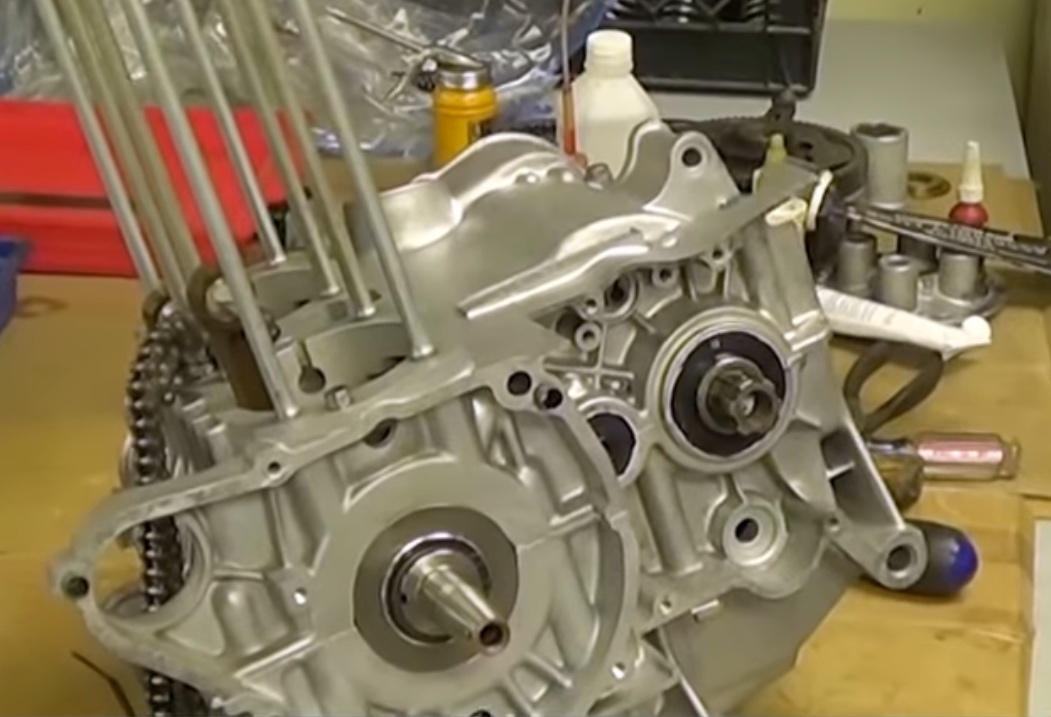

Being meticulous about lining up the crankshaft bearing dowels. |

Excellent, and something that can catch the unwary. |

|

Nothing about determining the condition of the main bearings. |

This is an important oversight as roller type bearings have more failure modes than do plain bearings. The first defense is to hear how the engine sounds while running. Bad crankshaft bearings make a sound similar to a train on train tracks. Short of that test, feeling for grit or skips or non-smoothness or discoloration is in order. |

|

No inspection of the connecting rods. |

The big end especially, for the same reasons as the crankshaft bearings. But the small end is important too because Hondas tend to burn their rods there, particularly on models such as the 450 that have a reputation for lubrication problems. |

|

No testing of the transmission for shifting. |

This one is hard to believe. It would seem the people in the video are as new to this as the video's target viewer. Further, throughout the five videos in this series, the mechanic missed at least two more opportunities to test the transmission. It cannot be over-emphasized how important this is. |

|

Threebond 1184 on crankcases. |

Good job! And used sparingly, too. For the record, Threebond 1184 is equal to the factory's Hondabond 4. Glad to see this. |

|

No inspection of the starter clutch. |

This is big. Even more unbelievable than not testing the transmission, no one who knows anything about this engine would overlook this. The only bigger pitfall on this engine, to the point that makes the engine not even worth rebuilding, is the issue of the inconsistent carburetor specifications across the 450 models. The starter clutch is the #2 concern, after the carbs. Way big. Not to be overlooked. |

|

The unique first steel clutch disc pointed out. |

Good one! This will be a big help to the do-it-yourselfer! Good job! |

|

Calls piston ring end-gap an "old school technique not done any more." |

Not so. While it is true that factory rings are pre-gapped and in nine out of ten cases can be assumed correct, they should still be checked. Further, these aren't factory rings and from appearances aren't even good quality rings. They definitely need to be gapped. Just as the mechanic shows. |

|

The cylinder deck appears to have been milled. |

It may not have been, but sure looks like it. If it has, this is a bad practice if done for reasons of improved gasket seal. It won't help the gasket seal, and it results in changes to cam timing and to the crucial valve-to-piston clearance, problems only an experienced high performance engine rebuilder wants to have to deal with. |

|

Putting new o-rings at the bottoms of the cylinder sleeves. |

Bravo! How many people overlook this. It has a huge effect on oil consumption! Excellent advice! |

|

Fixing cylinder base gasket to the cylinder. |

Another professional technique! This is much preferred over allowing the gasket to squirm around and shift on the crankcase while the cylinder assembly is being installed. This one is impressive. |

|

Warns about oil ring expander overlap. |

Very good! Something every beginner will need to know. |

|

No real inspection of valves, valve seats or valve guides. |

Without referencing it in these videos or linking it in any way that I could detect, Common Motor did do a separate cylinder and head video. Unfortunately, it also contains a few bad practices. For example, attempting to determine the condition of the cylinders by comparing their dimensions with those in the manual. The correct way is to determine piston-to-cylinder clearance. And this requires the pistons, which are neither shown or even mentioned in the video! Almost as bad, the cylinder and head video is pretty inadequate in the area of valve and valve seat inspection. Granted that is above the ability of many, but this is after all a series on engine rebuild. |

|

No comprehensive inspection of cams and followers. |

Once again, there is elsewhere on the website a video on inspecting the cams and followers--for a CB350. Aside from this being less relevant, I did not notice any reference to the cam video within the engine rebuild video. In the cams video, to their credit, Common Motor does recommend welded cams and followers as replacements, which is the only real solution for these old bikes. |

|

The copper washers are missing! |

Unless the video quality is to be blamed, there are apparently only steel washers on this cylinder head! Where are the two copper oil passage sealing washers? |

|

No camshaft thrust shims! |

I tried hard to spot them and did not. This engine has to have its cams' end-play carefully dialed in. If the end-play is excessive, the engine will knock. I also like the shims as protection against injuring the cam bearings, which does happen, though that is not their primary purpose. The shims are available from Sirius Consolidated. |

|

The cam chain master link is a peculiar, non-OEM style. |

What's up with the cam chain master link? A master link that is not crimped? I wouldn't trust that for a minute. The factory link is still available and should be used. |

|

The alternator cable isn't properly sealed. |

It's a good choice to use the Threebond, but a lot more of it than shown is needed. This spot is a significant weak area, very prone to oil leakage. Two or three layers of sealer, applied over time so each layer builds, is how it should be done. And it needs to include the individual wires, not just the rubber block, on both sides of the cover. |

|

Good explanation of the oil filter (centrifuge) cover oil path. |

Very useful to the beginner. The oil filter on this engine needs to get a lot more respect than it does. And a lot more attention maintenance-wise. |

|

Still more... |

There are more observations, but these will serve to warn the viewer that he is not learning best practices from this video. Common Motor has worked hard and overall has done some good work. No offense is intended, but watching this video is the same as watching the guy down the street work on his bike. |

|

For more powersports maintenance fallacies, see this article |

Email me

© 1996-2023 Mike Nixon