™ ™I s s u e 3

Okay, Issue number 3! Yeah! Loving it! You can find back issues of the Motorcycle Project Dispatch archived at this link.

The big news since early this year is that The Motorcycle Project has relocated its business center to Arizona! Yup, Prescott, Arizona. Aside from the mere change in locale, what this means for you the customer is that more space and even more time is now devoted to fulfilling your carburetor service and parts needs. A big deal to us at Motorcycle Project!.

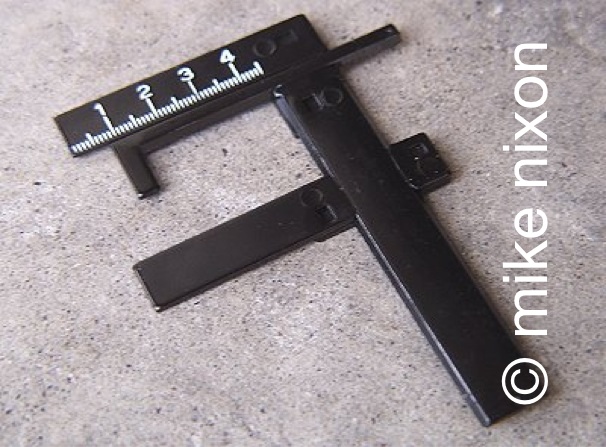

Don't overlook the Motorcycle Project's recreated Parts Shop, full of all kinds of carburetor specialty items, and a few other surprising things. One of those things is this universal adjustable float height gauge. A quality copy of the original Kowa item that Honda introduced in the early 70s and later Harley-Davidson and Kawasaki picked up also. This is a great tool and once you try it you'll feel like you can't do without it. And only $32 plus shipping. And bonus, here is a video on its use. Below you will also find a brief treatment of the ethic of setting float levels. Enjoy!

Of oourse, the Motorcycle Project is mostly engaged in carburetor rebuilding and as always I am happy to be your go-to source for your carburetor rebuilding needs. I do all Japanese carburetors and have a special love for multicylinders of the 70s and 80s, with CBXs, DOHC fours and Gold Wings a specialty. And since I'm kind of an old fart, I gravitate heavily toward the 70s Honda SOHC fours as well. But I do them all. Quality parts, quality work. Don't overlook the Motorcycle Project's recreated Parts Shop, full of all kinds of carburetor specialty items, and a few other surprising things. One of those things is this universal adjustable float height gauge. A quality copy of the original Kowa item that Honda introduced in the early 70s and later Harley-Davidson and Kawasaki picked up also. This is a great tool and once you try it you'll feel like you can't do without it. And only $32 plus shipping. And bonus, here is a video on its use. Below you will also find a brief treatment of the ethic of setting float levels. Enjoy!

Of oourse, the Motorcycle Project is mostly engaged in carburetor rebuilding and as always I am happy to be your go-to source for your carburetor rebuilding needs. I do all Japanese carburetors and have a special love for multicylinders of the 70s and 80s, with CBXs, DOHC fours and Gold Wings a specialty. And since I'm kind of an old fart, I gravitate heavily toward the 70s Honda SOHC fours as well. But I do them all. Quality parts, quality work.

Float Levels

There is an astonishingly pervasive notion among the riding public that a float's height spec is what it is so as to prevent fuel overflow and that, conversely, an overflow condition is therefore to be corrected by float level adjustment. Wrong. Very wrong. I am perplexed as to why this error is so widespread.

Carburetor overflow or leaking has many possible causes, in fact as many as a dozen. However none of these include too high a float setting. The most common cause on many vintage bikes is cracked overflow standpipes. Next on the list is improper float bowl venting. And there are many others.

But again, fuel overflow due to improper float height is almost impossible. Logic should tell you that if a carburetor were overflowing due to an excessively high float level, the bike would be so rich it would barely run. For the fuel level to get high enough to overflow, it would be so high that jetting would effectively nearly double.

Then why is the correct float level so important if not to avoid overflow, and how is it adjusted? The fact is, a carburetor's float level is purely a function of carburetor tuning. Like the main jet, slide needle configuration, and other tunable circuit specifications, the float level is what it is as a result of the manufacturer's tuning goals. The float level is one of the ingredients, and in fact the main one, that determines fuel air/fuel mixture. Period. In other words, float level is the gateway to mixture control, i.e. leanness or richness, for all the carburetor's circuits, and thus affects all of those circuits. A case in point. Honda's earliest V4 models connected their float bowl vents to the airbox for evaporative emissions reasons. However many of these same bikes surged at highway speeds because the carbs' bowl vents' connection to the airbox caused their fuel levels to change, resulting in surging and poor performance. This led to a factory service program wherein the vents were disconnected from the airbox by the dealer. Here's the thing. Part of the program included installing smaller main jets. Why? With the bowl vents removed from the airbox, fuel levels increased, requiring smaller main jets to compensate. See the effect fuel level has? Dramatic.

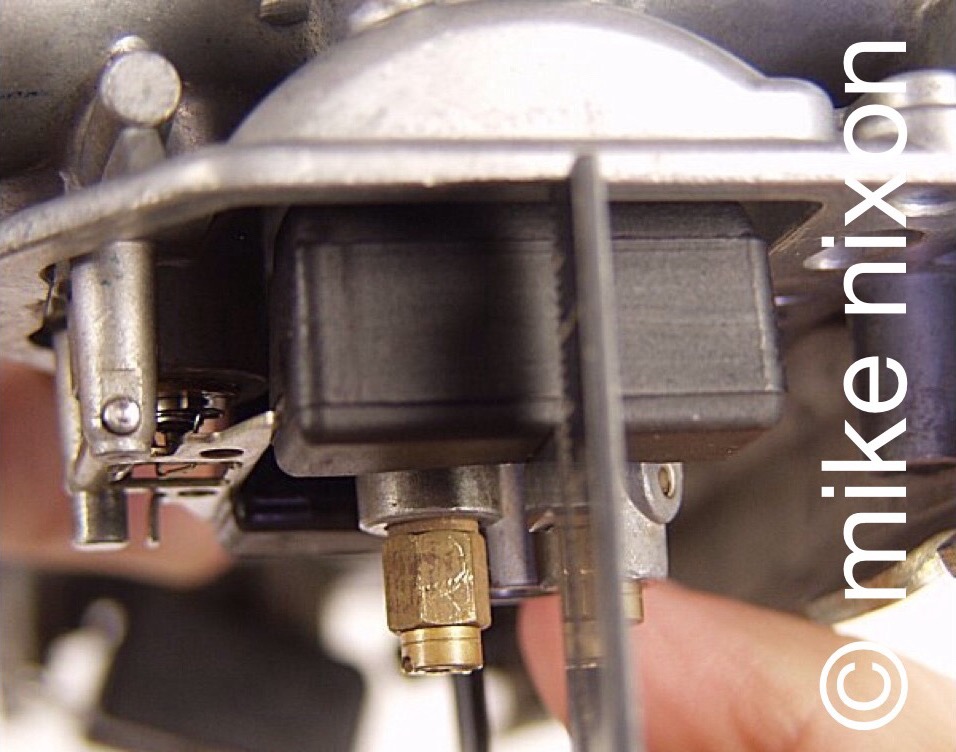

What about adjusting your carb's float level? Many seem to think the exact point at which a float shuts off the fuel's entry into the carburetor is a mysterious, difficult to obtain goal. But it's far from that. When the float valve has risen fully and has stopped, that is when the float's bottom edge is to be a certain height or distance from a strategic point on the carburetor casting. If the float is further than this prescribed distance when the valve closes then the fuel level will be resultingly lower, and the carburetor leaner overall. Conversely, if the distance at shutoff is less than specified, i.e. the float higher, richness will result. The spring-loaded pin on many float valves is there merely to be a shock absorber, to protect the valve and valve seat from repeated impact as the bike goes over bumps. It is not to be considered in the float setting at all. Simple, really.

What makes things confusing is when some recommend measuring the float height at all sorts of odd angles, including sideways and even upside-down. Where did the notion came from that a float level can be measured on a modern carburetor while holding the carburetor in anything but an upright orientation? It's only logical that it should be right side up. One of the things I see most frequently on carburetors that come in for rebuild is a misadjusted float, and I think most times it's because the carburetor was not held right side up during the process.

A simple system, the carburetor float. It detemines the carburetor's overall mixture. Whether 15mm, 21mm, 26mm or whatever, the manufacturer's float height specification is the starting point for all the carburetor circuits' air/fuel ratios. Adjust it to spec so your jets have a baseline from which to proper meter. Don't mis-adjust it to try to solve an overflow, thereby upsetting that carefully calculated metering, without having any effect on an overflow condition. Take the time do things right. Float Levels

There is an astonishingly pervasive notion among the riding public that a float's height spec is what it is so as to prevent fuel overflow and that, conversely, an overflow condition is therefore to be corrected by float level adjustment. Wrong. Very wrong. I am perplexed as to why this error is so widespread.

Carburetor overflow or leaking has many possible causes, in fact as many as a dozen. However none of these include too high a float setting. The most common cause on many vintage bikes is cracked overflow standpipes. Next on the list is improper float bowl venting. And there are many others.

But again, fuel overflow due to improper float height is almost impossible. Logic should tell you that if a carburetor were overflowing due to an excessively high float level, the bike would be so rich it would barely run. For the fuel level to get high enough to overflow, it would be so high that jetting would effectively nearly double.

Then why is the correct float level so important if not to avoid overflow, and how is it adjusted? The fact is, a carburetor's float level is purely a function of carburetor tuning. Like the main jet, slide needle configuration, and other tunable circuit specifications, the float level is what it is as a result of the manufacturer's tuning goals. The float level is one of the ingredients, and in fact the main one, that determines fuel air/fuel mixture. Period. In other words, float level is the gateway to mixture control, i.e. leanness or richness, for all the carburetor's circuits, and thus affects all of those circuits. A case in point. Honda's earliest V4 models connected their float bowl vents to the airbox for evaporative emissions reasons. However many of these same bikes surged at highway speeds because the carbs' bowl vents' connection to the airbox caused their fuel levels to change, resulting in surging and poor performance. This led to a factory service program wherein the vents were disconnected from the airbox by the dealer. Here's the thing. Part of the program included installing smaller main jets. Why? With the bowl vents removed from the airbox, fuel levels increased, requiring smaller main jets to compensate. See the effect fuel level has? Dramatic.

What about adjusting your carb's float level? Many seem to think the exact point at which a float shuts off the fuel's entry into the carburetor is a mysterious, difficult to obtain goal. But it's far from that. When the float valve has risen fully and has stopped, that is when the float's bottom edge is to be a certain height or distance from a strategic point on the carburetor casting. If the float is further than this prescribed distance when the valve closes then the fuel level will be resultingly lower, and the carburetor leaner overall. Conversely, if the distance at shutoff is less than specified, i.e. the float higher, richness will result. The spring-loaded pin on many float valves is there merely to be a shock absorber, to protect the valve and valve seat from repeated impact as the bike goes over bumps. It is not to be considered in the float setting at all. Simple, really.

What makes things confusing is when some recommend measuring the float height at all sorts of odd angles, including sideways and even upside-down. Where did the notion came from that a float level can be measured on a modern carburetor while holding the carburetor in anything but an upright orientation? It's only logical that it should be right side up. One of the things I see most frequently on carburetors that come in for rebuild is a misadjusted float, and I think most times it's because the carburetor was not held right side up during the process.

A simple system, the carburetor float. It detemines the carburetor's overall mixture. Whether 15mm, 21mm, 26mm or whatever, the manufacturer's float height specification is the starting point for all the carburetor circuits' air/fuel ratios. Adjust it to spec so your jets have a baseline from which to proper meter. Don't mis-adjust it to try to solve an overflow, thereby upsetting that carefully calculated metering, without having any effect on an overflow condition. Take the time do things right.

| Carbs | Parts | Heads | Electrical | Shocks | Books | Videos |

| Copyright © 2016 The Motorcycle Project |

|

™

™

™

™