™ ™I s s u e 2

Well, here we are at Issue 2. Yeah! Exciting stuff! I trust you have been waiting anxiously for this edition. No? Well, I can hope, can't I!? LOL! You can find back issues of the Motorcycle Project Dispatch archived at this link.

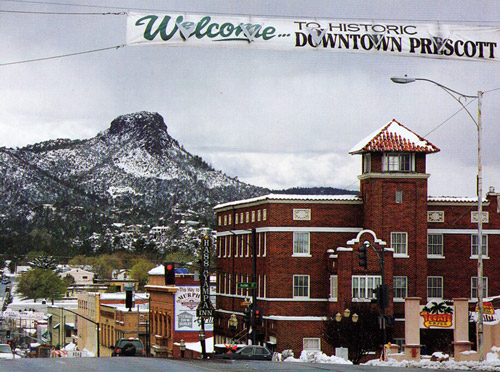

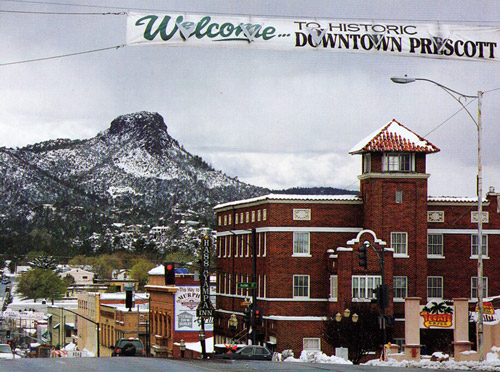

The big news this issue is that The Motorcycle Project has relocated its business center to Arizona! Yup, Prescott, Arizona. Aside from the mere change in locale, what this means for you the customer is that more space and even more time is now devoted to fulfilling your carburetor service and parts needs. A big deal to us at Motorcycle Project.

Other news is that the Motorcycle Project website is completely redesigned for 2016. Take a look, I think you'll like what you see, and I am especially proud of the new Parts Shop. One of the newest Motorcycle Project Parts Shop offerings is this Honda CBX Pro-Link shock seal.  Two years in the design and manufacture, this seal is an exact reproduction of the stock Honda item, down to the Viton composition, very tight tolerances and three-lip design, all rigidly specified and controlled during manufacture. An exact replacement in other words for the seal on the 81-82 CBX, 81-82 GL500, and 84-86 VF1100S. Though some special tools are required to properly install, they are easily fabricated and replacing the seal is not a difficult job, as the many folks who have bought this seal can confirm.

Of oourse, the Motorcycle Project is mostly engaged in carburetor rebuilding and as always I am happy to be your go-to source for your carburetor rebuilding needs. I do all Japanese carburetors and have a special love for multicylinders of the 70s and 80s, with CBXs, DOHC fours and Gold Wings a specialty. And since I'm kind of an old fart, I gravitate heavily toward the 70s Honda SOHC fours as well. But I do them all. Quality parts, quality work. Two years in the design and manufacture, this seal is an exact reproduction of the stock Honda item, down to the Viton composition, very tight tolerances and three-lip design, all rigidly specified and controlled during manufacture. An exact replacement in other words for the seal on the 81-82 CBX, 81-82 GL500, and 84-86 VF1100S. Though some special tools are required to properly install, they are easily fabricated and replacing the seal is not a difficult job, as the many folks who have bought this seal can confirm.

Of oourse, the Motorcycle Project is mostly engaged in carburetor rebuilding and as always I am happy to be your go-to source for your carburetor rebuilding needs. I do all Japanese carburetors and have a special love for multicylinders of the 70s and 80s, with CBXs, DOHC fours and Gold Wings a specialty. And since I'm kind of an old fart, I gravitate heavily toward the 70s Honda SOHC fours as well. But I do them all. Quality parts, quality work.

Carb Kits

Carburetor rebuild kits. The way to go, right? No, actually, they're crap. Whether K&L, Keyster, Napco, whatever -- you really don't want to use that stuff in your carburetors. Why not?

Okay, let's take a typical kit, one piece at a time. Let's start with the o-rings and gaskets. They're made of the absolute worst material the manufacturer could get away with, and are so soft in fact that they easily deform and even more readily sponge up fuel, both leading to swelling and consequent poor fitment and inevitable leaks. While an o-ring or gasket does not have to be Viton to do a good job, neither should it be the cheapest squishiest stuff on the planet. The rubber in these kits is glorified chewing gum. Next, the jets and other metal parts. Because the makers of these products can't hope to keep up with the slight changes Honda or another manufacturer made each year within just one model range, say the CB750 DOHC, their kits at best compromise, being marketed in only one or two versions for that entire five year range of bikes. The jets are often the wrong size, and in many cases not even the size they are marked! As for the most sophisticated parts, the needle jets and jet needles -- forget it! I have often nearly cried when finding Keyster parts in Honda carburetors. Typically, the unsuspecting customer threw away his perfectly good and actually very valuable stock parts. Finally, the float valves. Two kinds of float valves are found in jet kits, earlier style non-Viton tipped and later Viton tipped. Neither are worth using. Here's how bad they are. The steel tipped needles are actually made off-center. When tested with a vacuum tool such as a Mityvac, they will not hold air, though may may pass a quick fluid test. This does not speak well for their long term performance. The stock parts on the other hand, which are still available from Honda at least, pass the vacuum test every time. Which do you want in your carbs? The Viton-tipped kit float valves are not a lot better. First, their rubber tips are often glued off-center, and even when not, the glue doesn't hold over time and the tip comes off. Second, if that wasn't bad enough, these valves are univerally made of zinc, not aluminum like the factory ones. This is why they are plated, sometimes with chrome, often with zinc plating. The plating is there to shield the highly chemically reactive zinc metal from any outward influence from neighboring metals. The problem is, the zinc wears very quickly and actually corrodes under the plating, making the plating come off and the valve turn to trash. So if the valve seals at all during installation, it won't do so for very long. Again, very cheap, bottom shelf items. At The Motorcycle Project, these parts are not used in carburetor rebuilds. And now you know why. Carb Kits

Carburetor rebuild kits. The way to go, right? No, actually, they're crap. Whether K&L, Keyster, Napco, whatever -- you really don't want to use that stuff in your carburetors. Why not?

Okay, let's take a typical kit, one piece at a time. Let's start with the o-rings and gaskets. They're made of the absolute worst material the manufacturer could get away with, and are so soft in fact that they easily deform and even more readily sponge up fuel, both leading to swelling and consequent poor fitment and inevitable leaks. While an o-ring or gasket does not have to be Viton to do a good job, neither should it be the cheapest squishiest stuff on the planet. The rubber in these kits is glorified chewing gum. Next, the jets and other metal parts. Because the makers of these products can't hope to keep up with the slight changes Honda or another manufacturer made each year within just one model range, say the CB750 DOHC, their kits at best compromise, being marketed in only one or two versions for that entire five year range of bikes. The jets are often the wrong size, and in many cases not even the size they are marked! As for the most sophisticated parts, the needle jets and jet needles -- forget it! I have often nearly cried when finding Keyster parts in Honda carburetors. Typically, the unsuspecting customer threw away his perfectly good and actually very valuable stock parts. Finally, the float valves. Two kinds of float valves are found in jet kits, earlier style non-Viton tipped and later Viton tipped. Neither are worth using. Here's how bad they are. The steel tipped needles are actually made off-center. When tested with a vacuum tool such as a Mityvac, they will not hold air, though may may pass a quick fluid test. This does not speak well for their long term performance. The stock parts on the other hand, which are still available from Honda at least, pass the vacuum test every time. Which do you want in your carbs? The Viton-tipped kit float valves are not a lot better. First, their rubber tips are often glued off-center, and even when not, the glue doesn't hold over time and the tip comes off. Second, if that wasn't bad enough, these valves are univerally made of zinc, not aluminum like the factory ones. This is why they are plated, sometimes with chrome, often with zinc plating. The plating is there to shield the highly chemically reactive zinc metal from any outward influence from neighboring metals. The problem is, the zinc wears very quickly and actually corrodes under the plating, making the plating come off and the valve turn to trash. So if the valve seals at all during installation, it won't do so for very long. Again, very cheap, bottom shelf items. At The Motorcycle Project, these parts are not used in carburetor rebuilds. And now you know why.

| Carbs | Parts | Heads | Electrical | Shocks | Books | Videos |

| Copyright © 2016 The Motorcycle Project |

|

™

™

Two years in the design and manufacture, this seal is an exact reproduction of the stock Honda item, down to the Viton composition, very tight tolerances and three-lip design, all rigidly specified and controlled during manufacture. An exact replacement in other words for the seal on the 81-82 CBX, 81-82 GL500, and 84-86 VF1100S. Though some special tools are required to properly install, they are easily fabricated and replacing the seal is not a difficult job, as the many folks who have bought this seal can confirm.

Of oourse, the Motorcycle Project is mostly engaged in carburetor rebuilding and as always I am happy to be your go-to source for your carburetor rebuilding needs. I do all Japanese carburetors and have a special love for multicylinders of the 70s and 80s, with

Two years in the design and manufacture, this seal is an exact reproduction of the stock Honda item, down to the Viton composition, very tight tolerances and three-lip design, all rigidly specified and controlled during manufacture. An exact replacement in other words for the seal on the 81-82 CBX, 81-82 GL500, and 84-86 VF1100S. Though some special tools are required to properly install, they are easily fabricated and replacing the seal is not a difficult job, as the many folks who have bought this seal can confirm.

Of oourse, the Motorcycle Project is mostly engaged in carburetor rebuilding and as always I am happy to be your go-to source for your carburetor rebuilding needs. I do all Japanese carburetors and have a special love for multicylinders of the 70s and 80s, with  Carb Kits

Carburetor rebuild kits. The way to go, right? No, actually, they're crap. Whether K&L, Keyster, Napco, whatever -- you really don't want to use that stuff in your carburetors. Why not?

Okay, let's take a typical kit, one piece at a time. Let's start with the o-rings and gaskets. They're made of the absolute worst material the manufacturer could get away with, and are so soft in fact that they easily deform and even more readily sponge up fuel, both leading to swelling and consequent poor fitment and inevitable leaks. While an o-ring or gasket does not have to be Viton to do a good job, neither should it be the cheapest squishiest stuff on the planet. The rubber in these kits is glorified chewing gum. Next, the jets and other metal parts. Because the makers of these products can't hope to keep up with the slight changes Honda or another manufacturer made each year within just one model range, say the CB750 DOHC, their kits at best compromise, being marketed in only one or two versions for that entire five year range of bikes. The jets are often the wrong size, and in many cases not even the size they are marked! As for the most sophisticated parts, the needle jets and jet needles -- forget it! I have often nearly cried when finding Keyster parts in Honda carburetors. Typically, the unsuspecting customer threw away his perfectly good and actually very valuable stock parts. Finally, the float valves. Two kinds of float valves are found in jet kits, earlier style non-Viton tipped and later Viton tipped. Neither are worth using. Here's how

Carb Kits

Carburetor rebuild kits. The way to go, right? No, actually, they're crap. Whether K&L, Keyster, Napco, whatever -- you really don't want to use that stuff in your carburetors. Why not?

Okay, let's take a typical kit, one piece at a time. Let's start with the o-rings and gaskets. They're made of the absolute worst material the manufacturer could get away with, and are so soft in fact that they easily deform and even more readily sponge up fuel, both leading to swelling and consequent poor fitment and inevitable leaks. While an o-ring or gasket does not have to be Viton to do a good job, neither should it be the cheapest squishiest stuff on the planet. The rubber in these kits is glorified chewing gum. Next, the jets and other metal parts. Because the makers of these products can't hope to keep up with the slight changes Honda or another manufacturer made each year within just one model range, say the CB750 DOHC, their kits at best compromise, being marketed in only one or two versions for that entire five year range of bikes. The jets are often the wrong size, and in many cases not even the size they are marked! As for the most sophisticated parts, the needle jets and jet needles -- forget it! I have often nearly cried when finding Keyster parts in Honda carburetors. Typically, the unsuspecting customer threw away his perfectly good and actually very valuable stock parts. Finally, the float valves. Two kinds of float valves are found in jet kits, earlier style non-Viton tipped and later Viton tipped. Neither are worth using. Here's how