The Importance of Air

The Importance of Air

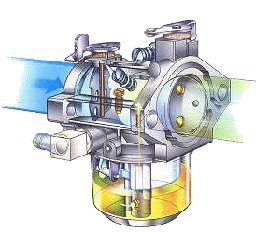

Carburetors can be intimidating. They can get a novice in trouble fairly quickly. However, many people have trouble with carburetors because they look at them wrong. They see them as primarily fuel instruments, when in fact they are not. The verb "carburet" actually means, "to permeate with carbon." The carburetor is, you see, a device by which something is charged with carbon. That something is air. Air is the working medium in combustion, and so it is in carburetion. The fuel, the hydrocarbon that the air is laced with, is of secondary importance to the carburetor, and to some extent even to the engine. The carburetor and engine move air. The fuel comes along for the ride, so to speak, mainly to heat the air and thereby create pressures that will result in more air movement.

Not convinced? Try this: Start and warm up your gasoline-engined lawnmower. Shut it off and carefully but quickly remove the carburetor. Pour about a teaspoon of gasoline into the manifold and promptly pull the start rope. The engine will rev gloriously wide-open -- keep a hand on the kill switch! A little hair-raising, isn't it? You've just observed a curious thing. Namely, that very little quantitative relationship exists between fuel and rpm. You will intuitively conclude from this experiment that one does exist between air and rpm. And you'll be right. You've learned something very important, something many mechanics struggle with. The internal combustion engine runs on air, not fuel, and the carburetor is consequently more an air instrument than a fuel instrument. In fact, ultimately, the coursing and throbbing of air through the engine determines, unlike anything else, the engine's power characteristics. The end result is either the Harley's rumpety-rumpety (due largely to a veritable cyclone of confused and contradictory air currents), or the Hyabusa's ripping silk (the result of its shrieking high speed intake). Air is the engine's medium, fuel is merely the catalyst. So basic is this principle to internal combustion design that in order to comprehend any of the grand mysteries of internal combustion -- from the origin and nature of torque, to the practical advantages of fuel injection -- one must embrace the immense importance of the vagaries of the behavior of air within the internal combustion engine. It is paramount.

The Carburetor's Beginning

What's the point? Well, with the importance of airflow in mind, consider the following. As air rushes through the carburetor on its way into the engine, it is forced to accelerate through a  narrowed part of the carburetor called the venturi. A low pressure pocket is created at this point of the air's acceleration. The carburetor designer suspends a tube from this place and submerges it into fuel. Fuel will then wick up the tube and into the intake manifold of the engine. Just as in a plant sprayer, the fuel is encouraged up the tube by the differences in pressure. The difference between the fuel at atmospheric pressure and the venturi at less than atmospheric pressure. You've just learned about the venturi principle.

narrowed part of the carburetor called the venturi. A low pressure pocket is created at this point of the air's acceleration. The carburetor designer suspends a tube from this place and submerges it into fuel. Fuel will then wick up the tube and into the intake manifold of the engine. Just as in a plant sprayer, the fuel is encouraged up the tube by the differences in pressure. The difference between the fuel at atmospheric pressure and the venturi at less than atmospheric pressure. You've just learned about the venturi principle.

But right away we have a problem. This seemingly magically moved fuel is being discharged in sheets. The engine doesn't like that. It prefers an air/fuel mist -- droplets -- because a mist is easier to vaporize (turn into a gas -- the engine won't burn a liquid). To get that mist, the carburetor's fuel tubes have to be drilled  full of a lot of little holes. These holes are connected to an atmospheric vent in the carburetor. This system will cause the fuel to aerate as it rises upward. It's called an air bleed, and every carburetor has at least one. Something else every motorcycle carb has is more than one fuel tube. Though lawnmowers make do with just one tube, motorcycles speed up, slow down and wait at stop lights. Bike carburetors therefore have to

full of a lot of little holes. These holes are connected to an atmospheric vent in the carburetor. This system will cause the fuel to aerate as it rises upward. It's called an air bleed, and every carburetor has at least one. Something else every motorcycle carb has is more than one fuel tube. Though lawnmowers make do with just one tube, motorcycles speed up, slow down and wait at stop lights. Bike carburetors therefore have to  have separate tubes for idle, midrange, and high rpm. Each is progressively larger, and each has its own air bleed. At this stage we have the classic three-tube, open-venturi carburetor that reigned supreme on motorcycles for nearly fifty years.

have separate tubes for idle, midrange, and high rpm. Each is progressively larger, and each has its own air bleed. At this stage we have the classic three-tube, open-venturi carburetor that reigned supreme on motorcycles for nearly fifty years.

The Carburetor's End

But this carburetion was fairly crude. Enormous amounts of circuit overlap compensated for poor air velocity characteristics. Mixtures erred heavily on the rich side to ensure compatibility with the period's weak ignitions. Mixture strength described horribly wide swings throughout the engine's rpm range. Carburetion such as this was a standard feature well into the 1960s, though dramatic improvements came soon enough.

The Idle Mixture Screw

The Idle Mixture Screw

One example of this state of affairs is the earliest idle mixture adjustment system. The idle mixture screw adjusted the idle circuit's richness by adjusting only half of the circuit -- the air half. Threaded into the idle air bleed, the screw was turned in to decrease the amount of air mixing with the fuel already rising in the idle circuit, or out to permit more air to mix. Unfortunately, this changed the air/fuel ratio of the circuit, not just the amount of mixture expelled by it. Consequently, mixture distribution in the cylinder was uneven, and combustion efficiency decreased. In addition, because the mixture screw’s tip was very blunt in shape, a very small adjustment resulted in a largish change in mixture ratio. Consequently, less than expert twiddlers frequently fouled things up, and even if the engine could tolerate the misadjustment, our environment could not.

This early idle system's poor atomization drew for the carburetor more than its share of scrutiny and marked the carburetor for eventual extinction. Even as the watershed 1977 revision to the Clean Air Act (which for the first time targeted motorcycles) was being written, a stopgap measure to appease the feds was already in place. You see, the manufacturers couldn't just remove the screw. An internal combustion engine is its least efficient at idle. This means that even after it is perfectly adjusted, the idle mixture may be incorrect once conditions change even slightly. Therefore, every carburetor has to have an idle mixture adjustment screw. Even outboard motors have them. Soon, carburetor manufacturers began hiding the offending screw under a plastic cap.  Of course, this was easily removed by knowledgeable tinkerers, but the uninitiated were effectively befuddled. The following year, manufacturers responded to even stricter regulatory demands by moving the screw from the air-only passage to a point further downstream where both air and fuel discharged together. This was an intelligent innovation. It made the idle mixture adjusting system much cleaner because now when the screw was turned inward, the change affected both air and fuel at the same time, instead of just the air. That is, the quality of the circuit's atomization stayed the same while the quantity of the air/fuel mixture was adjusted. The screw was also given a sharply pointed tip, one much more forgiving, emissions-wise, of inexpert fiddling. This change, from an air screw to a fuel/air screw, seems minor but was in reality an important event. It probably single-handedly extended the legal useful life of the carburetor by perhaps twenty-five years.

Of course, this was easily removed by knowledgeable tinkerers, but the uninitiated were effectively befuddled. The following year, manufacturers responded to even stricter regulatory demands by moving the screw from the air-only passage to a point further downstream where both air and fuel discharged together. This was an intelligent innovation. It made the idle mixture adjusting system much cleaner because now when the screw was turned inward, the change affected both air and fuel at the same time, instead of just the air. That is, the quality of the circuit's atomization stayed the same while the quantity of the air/fuel mixture was adjusted. The screw was also given a sharply pointed tip, one much more forgiving, emissions-wise, of inexpert fiddling. This change, from an air screw to a fuel/air screw, seems minor but was in reality an important event. It probably single-handedly extended the legal useful life of the carburetor by perhaps twenty-five years.

Of course, there was still the problem of just finding the idle mixture screw in the first place. On many carburetors, the screw quickly migrated to the bottom of the casting, which all but hid it from view. In following years, an aluminum limiting cap was super-glued over the screw, and to address the possibility that some would be clever enough to locate it, the screw was purposefully made with a narrow-necked, break-off head. That is, the screw was designed to break nicely in two under any  attempt to remove the limiting cap. Gotcha! (It was apparently assumed that if you didn't know how to get the aluminum cap off without breaking the screw, you couldn't possibly know how to properly adjust the idle mixture.) Once the screw broke, the carburetor had to be removed and the sacrificial screw extracted and replaced. At this stage, idle mixture adjustment of the modern carburetor was clearly relegated to the trained professional having the proper special tools and knowledge.

attempt to remove the limiting cap. Gotcha! (It was apparently assumed that if you didn't know how to get the aluminum cap off without breaking the screw, you couldn't possibly know how to properly adjust the idle mixture.) Once the screw broke, the carburetor had to be removed and the sacrificial screw extracted and replaced. At this stage, idle mixture adjustment of the modern carburetor was clearly relegated to the trained professional having the proper special tools and knowledge.

Emissions-driven shenanigans such as this were ultimately to remove all vestiges of the familiar motorcycle and ATV carburetor as other circuits and passages historically designed to be tuned became, one by one, similarly nonadjustable. The jet needle lost its adjustment grooves, the float's adjustable metal tang disappeared, and in a few cases the threads (and screwdriver slot) were removed from the carb's jets. Eventually, the carburetor wasn't even allowed to vent to atmosphere unless the engine was running, and then only through a system of vapor traps and automatic valves. Finally, after all this government meddling, the besieged carburetor cried "uncle," and fuel injection came into its own.