Two things about carburetor float levels seem to be vastly misunderstood. Please consider these things carefully. I encourage correspondence.

Two things about carburetor float levels seem to be vastly misunderstood. Please consider these things carefully. I encourage correspondence.

First, float level and its connection to float bowl overflow. There is an astonishingly pervasive notion among riders that the height of the carburetor's float is somehow linked to float bowl overflow. In other words, that a float's height spec is what it is so as to prevent fuel overflow and that conversely, and to the point, an overflow condition is therefore to be corrected by float level adjustment. I am perplexed as to why this error is so widespread.

Overflow has many possible causes, however none of them include too high a setting. The most common on many vintage bikes is cracked overflow standpipes. At least half of all the carbs I rebuild have to have their standpipes repaired. Next is poor venting, whether due to blocked bowl vent passages or improperly installed or routed vent hoses. And then finally, there is the leaking float valve, which is common only when using aftermarket float valves. It appears that many carb rebuilders do, and this too surprises me.

However, improper float level is extremely rare as a cause of fuel overflow. Logic should tell you that if a carburetor were overflowing due to an excessively high float level, you would know about it by the way the engine ran long before you became worried about the overflow. The fact is a carburetor's float level, whether as specified by the manufacturer or as determined by trial and error, is purely a function of carburetor tuning. A carburetor's float rations fuel from the fuel tank, stopping fuel flow from the tank when there is predetermined amount. Naturally. However, that explains only why the float is there, not why it has a certain prescribed height. Like the jets, slide dimensions and even the carb's bore size, the float level is one of the ingredients that determines fuel air/fuel mixture. Period. Race tuners appreciate this, as they use float level in the same way they use jets, adjusting it along with the others to suit tuning needs. As also do carburetor manufacturers. A case in point. Honda made V4 models that were carbureted some time ago. The earliest models connected their float bowl vents to the airbox, presumably for evaporative emissions reasons. However many of these bikes surged at high speeds. The carbs' vents connection to the airbox caused fuel levels to oscillate due to engine pulses and generally lowered average fuel levels due to negative pressure, resulting in the surging and poor performance. This led to a specification change later wherein the vents were disconnected. Here's the thing. The disconnected carbs had smaller main jets. The reason is they had higher fuel levels. Again, there is a direct link between float level and air/fuel mixture richness.

I recently talked with a builder of a custom motorcycle who was not aware of the connection between fuel pressure and float level. He didn't understand that the addition of a fuel pump to a previously non fuel pump equipped motorcycle might warrant a change in the carburetor's float level. I found it interesting that he did not consider that the added fuel pressure will likely result in a higher fuel level, necessitating in turn a lower float setting.

Speaking of fuel pumps, not many folks are aware that not all of the fuel pumps found on motorcycles are there for the reasons they think. Early Honda V4s have been raced with their fuel pumps removed to save weight. How can that be? Everyone knows the fuel pumps are there because the carbs are so close to the fuel tanks that there is very little gravity pressure on the fuel. What is not well known however is that the bikes run fine without the pumps because they are there more to ensure consistent fuel pressure than to ensure an absolute pressure figure. In fact, in these cases the fuel pumps are actually emissions devices. The stricter control of fuel pressure makes it easier for the manufacturer to federally certify a given exhaust emission. Incidentally, this is the main advantage of liquid cooling of motorcycle engines as well. The cooling system thermostat is also an emissions device.

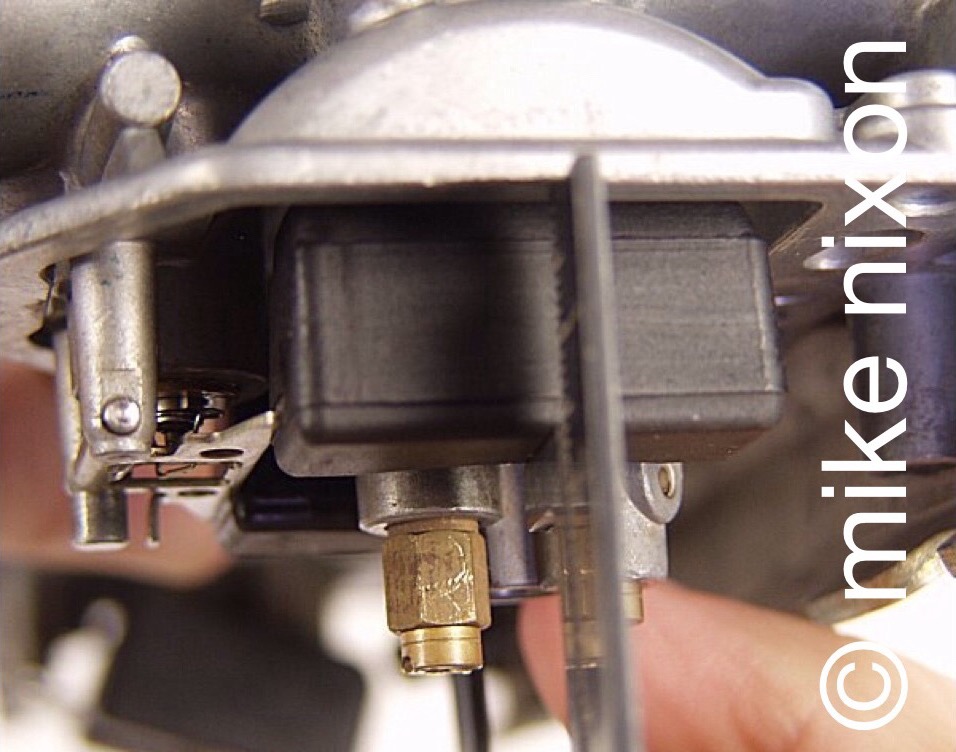

The second thing I am concerned about in the area of carburetor floats is the lack of understanding of how to adjust float level. Many seem to think the exact point at which a float shuts off the fuel's entry into the carburetor a mysterious, difficult to obtain goal. It's not, of course. When the float needle, or valve, has risen fully and has stopped, that is when the float's bottom edge is to be a certain height or distance from a strategic point on the carburetor casting. If the float is further than this prescribed distance when the valve shuts off the fuel level will be resultingly lower, and the carburetor leaner overall. Conversely, if the distance at shutoff is less than specified, the float is higher than it's supposed to be, the fuel level also, and richness will result. The spring-loaded pin on most float valves is there merely to be a shock absorber, so as to protect the valve and valve seat from repeated impact as the bike goes over bumps. It is not to be considered in the float setting at all. That is, it is not permitted to compress. Simple, really. What makes it confusing is when some recommend measuring the float setting at all sorts of odd angles, including sideways and upside-down. Where did the notion came from that a float level can be measured on a modern carburetor while holding the carburetor in anything but an upright orientation? It's only logical that it should be right side up. One of the things I see most frequently is a misadjusted float, and I think most times it's because the carburetor was not held right side up during the process.

A simple system, the carburetor float. But so widely misunderstood. Hopefully this exploration has put some light on the subject.