® ®

|

Bad Practice |

|

|

|

| Some carburetors came to me that had been done by someone else. They had an abrasive blasted appearance. | You can see here the texture that abrasive leaves. This is quickly becoming the standard finish many carb builders provide. | Close up. It's a nice finish, but at what cost to the carburetors? |

|

|

|

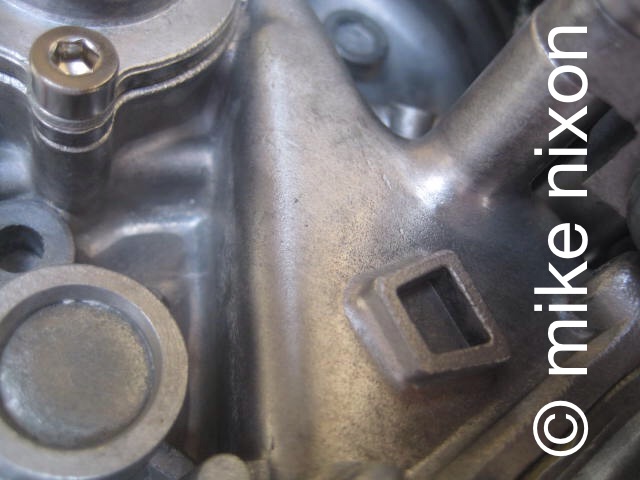

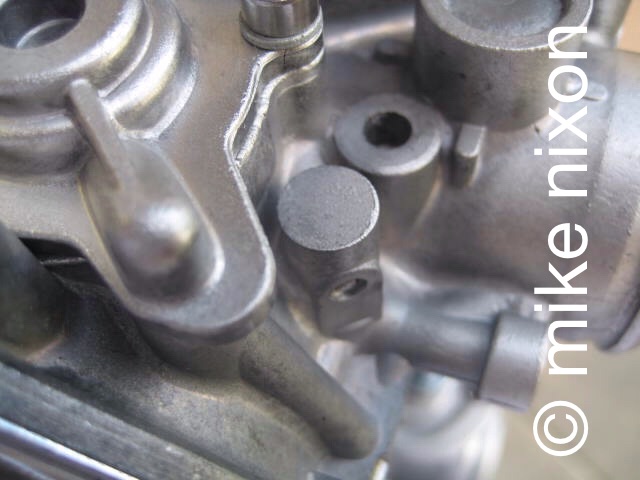

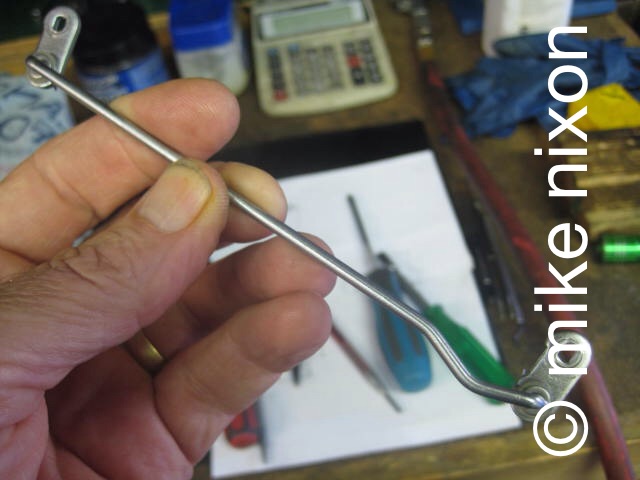

| Another closeup. Pretty. Hard to fault that. | There are two problems with abrasive blasting. First, there are just too many tiny holes waiting to be clogged by abrasive media. Second, rebuilders who do abrasive blasting, as this individual did, usually do the blasting with the carburetors intact. This is an aluminum fuel passage tube. See the abrasive etching showing that the carbs were blasted whole? | So what? Well, look at the brackets and linkages. Blasting removes their protective zinc plating. This is the throttle bracket from the same carburetors. |

|

|

|

| None of the steel parts escape damage when the carbs are abrasive blasted intact. This is part of the choke linkage. Bare, exposed steel. | And here is the choke actuator. No plating. So what? Well, what's going to happen a little while down the road? Yup, all of this steel will be covered with ugly red rust. Some rebuilders justify this by saying they spray clear lacquer on the parts after blasting their protective finish off. How long is that going to work, do you think, in a fuel mist environment? | This rebuilder even blasted the jets, which is also very common. Note the rough handling on the idle jet, which is buggered up from a screwdriver. |

|

|

|

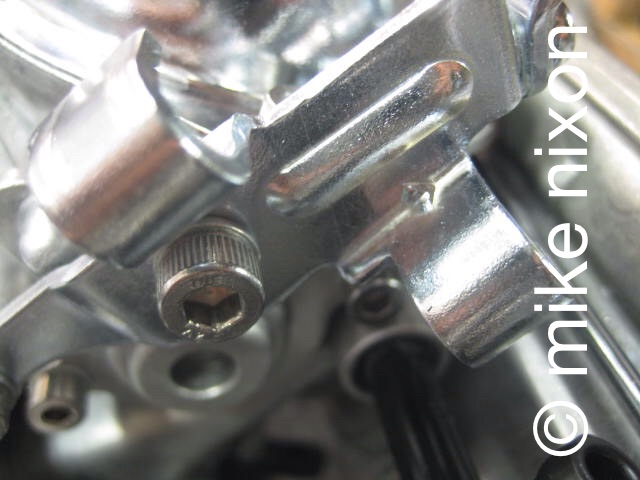

| I am not a big fan of Allen screws. They're okay, but the factory Phillips screws are superior in many ways. | The biggest problem with Allen screws is they are too easily over-tightened. The fact that I had to use an L wrench on the float bowl screws confirms they were too tight. | This is the correct tool, and the one I tried to remove the screws with. Wouldn't budge. You think this is good? |

|

|

|

| This rebuilder also used the ubiquitous aftermarket plated zinc float valves. Absolute junk. It is a mystery to me how anyone can justify using these. | The solution for this customer was to replate all the naked steel parts. Here is the choke linkage. | Here is the throttle cable bracket. |

|

|

: |

| And the throttle return spring. | And the sync adjusters. |

|

Last updated February 2026 Email me www.motorcycleproject.com My bio © 1996-2026 Mike Nixon |