|

Though I have never made it to Daytona, some of the bikes I fashioned while at Eastside Perforamnce did. Following are pictures of several projects, including one or two horsepower shootout bikes, as well as other things I worked on.

|

|

This machine is owned by one of Phoenix' largest contractors, Billy Johnson. Engine is near stock, with just bathtub heads over 3.517" pistons, plus a mild Andrews EV79 cam, and of course, N2O. Note the nitrous bottle, which most of the H-Ds coming out of Eastside Performance wear.

|

|

Cruiseamerica owner Bob Smalley's bike started out as a 1987 Harley-Davidson FXRS. Sporting STD 30o dual-plug heads ported by Carl's Speed Shop, a 0.620" cam, Axtell cylinders, a Bandit clutch, a Tech starter, and a RevTech carburetor mated to an S&S air cleaner, the 13:1 CR bike cleared 120 rear wheel horsepower on almost its first dyno session. The machine placed in the top five at Daytona's 1995 Harley shootout. The bike made 195 hp on the bottle. The entirely civil, electric-starting bike was a joy to ride. After building it, I rode it around for several days to break it in and flight-test it, and during that time all I could think of was a piped V-Max with 1" handlebars. It had that kind of acceleration.

|

|

Here is Bob's bike in its finishing stages. We used a Dill's SPL-1000 battery, which required that the oil tank be sectioned and moved forward slightly. The height of this 114" stroker also required that the front engine mount be installed upside-down. This shot shows the heads still off.

|

|

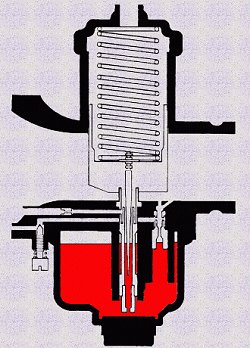

Import stuff is actually my strong suit. This sand rail is powered by a Kawsaaki KZ1100 engine. It began as a rolling chassis and several boxes of parts, including a tired and heavily-damaged engine. I machined several billet pieces for the fuel, throttle, and electrical system controls. The cylinder head came from a crashed motorcycle, and had to be reconstructed, including fabrication, welding and reshaping of many of the cooling fins. I made the deep oil sump from an automotive air conditioning dryer canister. The nitrous system uses fogger nozzles and throttle, rpm and fuel pressure safety switches, and it and the MSD ignition function through a custom-made wiring harness.

|

|

This little beauty is a later Ninja 750 engine, hooked up to a early Kawasaki turbo unit, and dropped into an automotive sand rail. Note the Autometer tach, which most of the machines we put together use.

|

|

As Motorcycle Mechanics Institute's Curriculum Developer (1998~2002), I updated the school's Harley-Davidson elective program. Click here for a sample of the lesson plan (in this case, for the high performance ER&P section). Be patient. This takes a while to load. When finished looking, use your browser's BACK button to return here.

|

|

This is a set of instructions I wrote for a special tool to separate and reconnect the cam chains used on most overhead cam engines. Click here to view the document. I also wrote a set of instructions for Progressive Suspension to use in their spring kits. This takes a while to load. When finished looking, use your browser's BACK button to return here.

|

|

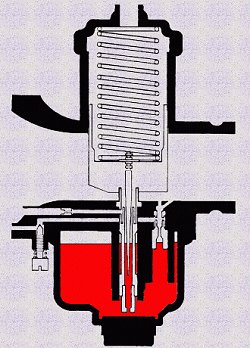

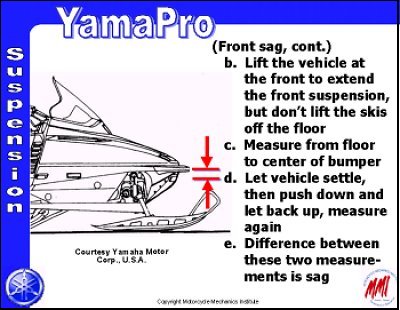

Here is a short animation that shows a little of the kinds of things I did while with Motorcycle Mechanics Institute (Universal Technical Institute). Animations such as this one were used in curriculum, and delivered to the students electronically. Be patient, this takes a few minutes to load. Click here to view the animation. Use your browser's BACK button to return here.

|

|

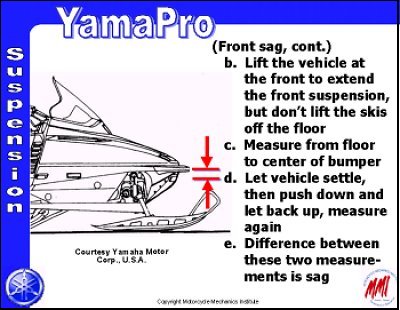

While with Motorcycle Mechanics Institute, I converted the school's curriculum into colorful, computer-based presentations done in PowerPoint.

|

|

Thank you for this opportunity to show you my background and qualifications.

|