|

|

Mechanics have known for nearly a hundred years that loose valve clearances are better than tight ones. It's only the inexperienced and those outside the industry who doubt it.

|

There is some debate on user forums about the value of setting motorcycle valve clearances to a spec at the ends of their factory-recommended ranges. As a lifetime tech, the fact that this is even questioned surprises me. It is well known among career motorcycle mechanics that targetting the large end of the valve adjustment range is always a good thing, never a bad one, and in a few special cases, even critical. Two reasons come readily to mind, valve recession and valve seat drift.

Valve recession

This is the biggest problem in bikes made since the early to mid 1970s, and with Japanese machines in paricular it borders on the endemic. Valve recession is simply the valve gradually, over time, sinking into its seat, due to wear of the valve (mostly) and the seat. Valve recession results in a gradual loss of valve seal because the receding valve's face takes a stepped shape onto its originally very flat surface. Asian engines are likely over-represented in valve recession, with their plated, soft-metal valve construction and subsequently faster valve wear. Also, probably due to how their vehicles are used, that is, with a lot more of their time spent at higher rpm, air-cooled singles and twins of every stripe are at especially high risk for accelerated valve recession, with a rather more rapid than usual observable recession pattern in such engines. But all engines recede their valves, even liquid-cooled, multicylinder, moderately-loaded ones. Valve recession is in fact the most ubiquitous valve wear condition one finds during an engine rebuild. It's the normal valve wear pattern. But while valve recession may be considered normal, in many cases it is very rapid. By less than 20,000 miles the cylinder compression may be at 2/3 its normal value.

Valve seat drift

Valve seat drift is another reason some engines respond particularly well to loosened valve clearances. Whereas valve recession is an expected and anticipated form of wear, valve seat drift on the other hand is much more unusual. Few engines do it. Seat drift is symptomatic of compromises made in manufacture. A valve's seat drifts when its host cylinder head gets very hot and the seat moves around a bit. The result is loss of valve sealing because the seat is no longer on the same center as the valve. Fortunately, the drift has been observed to be a one-time occurance; the seat quickly takes a "set" and does not afterward move around. Such was the case with early Honda cars. It used to be said among Honda car mechanics that if you owned one yourself you had better pull the head off and refinish all the valve seats within the first few thousand miles, then you could expect maximum cylinder head performance for the life of the car. As much as this sounds like an urban myth, the reality of it is it was true. (If you doubt that valve seats can get out of position, what do you suppose happens when the cylinder head gasket surface becomes warped, as it frequently does? Is it unthinkable that the rest of the head would shift also?) And it has been observed on powersports engines as well. It's no secret that Honda DOHC fours and the CBX often suffer from low cylinder compression, despite correct valve clearance. Between valve recession and seat drift, huge compression losses in these engines is legendary.

Automatic compression release realities

A third and somewhat unrelated case in which enlarged valve clearances prove beneficial is when the engine has a cylinder compression release built-in. Many ATVs, V-Twin cruisers, big-bore offroad singles and other high-torque engines have cylinder compression releases that operate automatically for improved engine starting. The trouble is, even when working correctly, these systems often reduce cylinder compression a little too much, resulting in hard-starting issues. Slightly increased valve clearances are effective in eliminating hard starting in these kimds of engines. Enterprising techs have also found ways to modify the compression release mechanisms for improved starting.

Looser valve clearances

Obviously, valve recession are valve seat drift are both correctable and a proper valve job is indicated in these instances. But what does setting the valve clearances to the ends of their ranges do? It is simply a workaround, a stopgap. It compensates to an extent for the bad valve seal by mathematically increasing cylinder compression time (in cramkshaft degrees) without appreciably affecting anything else valve or cam related. For every 0.001" clearance over the nominal 0.003" factory specification for DOHC fours and CBXs, for example, you stand to gain between 10 and 20 psi cranking pressure. It's as close to a free lunch as you're going to get. Even better than free, because it actually works.

The effect on valve timing

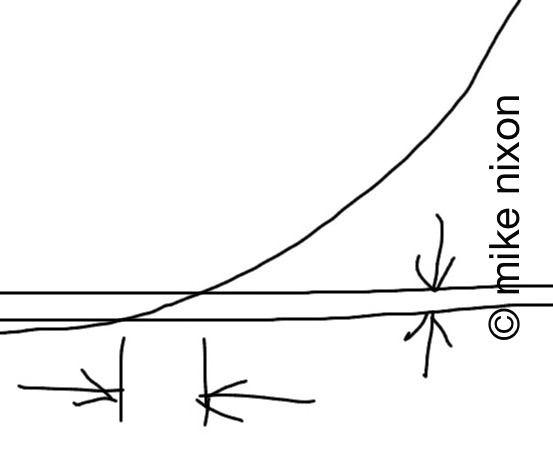

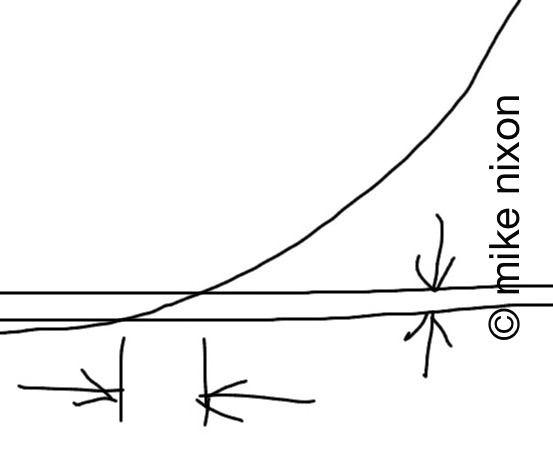

|

|

As this graph illustrates, a few thousandths of an inch increase in valve clearance creates two changes. The total valve lift, of course, and also the valve timing, that is, when the valve opens. Note which is affected more, the timing. By quite a lot. Whereas the lift is changed by only those few thou, negligible by anyone's standard, the timing on the other hand is altered by several crankshaft degrees, a very significant amount. And therein lies its effectiveness.

|

Some forum members have protested that loosening the valve clearances in this way reduces performance through reduced valve opening distance and/or reduced valve open time. Actually, this just isn't so. First let's address the change in valve open duration. The roughly 5 degrees of extra cylinder compression gained by looser valve clearances has the effect it does because compression is largely a mechanical function. However, engine tuning, the object of the protest, is not heavily dependant on mechanical but on gas waves and pressures, and these are much less affected by a few degrees change in valve open duration. (In fact, stock 1980s Honda engines lack the valve open specifications that would make their engines sensitive to small changes in valve opening.)

The effect of valve duration

As for the other half of the complaint, the reduction of cylinder head flow from the few thousandths lost in valve open distance, consider that 0.001" represents less than one half of one percent (0.003, i.e. 1/300th, to be exact) of the 1980s Honda four and six cylinder machine's valve's total opening amount. While it has an appreciable and real-world effect on cylinder compression, when it comes to intake and exhaust flow through the valve, a few thousandths less valve opening is so miniscule as to be less than neglible. How neglible? Your bike's cams actually wear about this much every 5,000 miles. Please remember also that we are not talking highly tuned engines here. Going back to my comment two paragraphs above about these engines not having much camshaft, understand that 80s-era Hondas have so little valve open time to begin with that no manner of tuned exhaust, for example, has any effect on them. Their valves are not open enough time in the engines' cycles to allow their exhausts to bring to bear any tuning principles. Thus small changes in valve open time, in either direction -- whether more or less duration -- aren't going to have any detectable effect.

Summation

I have studied this subject for a long time and I have proven the concepts. But really, I hardly had to. Reasonably diligent observation shows that loosening valve clearances is immediately and dramatically beneficial to many different kinds of engines, but particularly certain models and types of engines that inherently suffer from valve sealing issues, of engines which there are plenty in powersports. And this with absolutely no drawbacks.

®

®