- Q: Why is this method called a 3-step method, when there are seemingly dozens of tests?

A: There are actually only threetests of three functions Ė 1) rotor/regulator operation, 2) stator output, 3) and the final retest of charging output (amps). The tests mentioned in-between are part of the main tests and merely confirm them. Remember to think of this method as testing systems, and not just parts.

- Q: Why don't you use the official manual's test methods?

A: Two reasons. Most importantly because there is no methodology in the manual -- it offers tests but no logic. Second, the tests offered are the least conclusive type, a fact borne out by the manual's inevitable recommendation to "replace with known good component." Whatever you call it, that is not troubleshooting.

- Q: Why donít you use industry-standard terminology in your explanation of the SOHC charging system and its function?

A: Because there is no standard terminology in the powersports (motorcycle, scooter, ATV, snowmobile, and personal watercraft) industry. The industry has traditionally used confusing and contradictory terminology, and most change their terminology for the very same part from one year to the next. A generic, non brand-specific approach is the only way that makes sense.

- Q: You speak of the regulator as a supplying part, when most people assume it to be a limiting part. Can you reconcile this difference in descriptions?

A: Sure. The regulator is both. It is a supplying part in that it supplies electricity to the rotor to make it magnetized. But it is also a limiting part in that it controls how much electricity the rotor gets to increase or decrease its magnetism as needed to control charge.

- Q: Explain about the hydrometer and battery load tester.

A: A hydrometer is a tool that measures the density of the electrolyte (fluid) inside your battery, which increases with charge and decreases as the battery ages. This density is therefore one of the surest ways to accurately determine the condition of a flooded cell type battery, if the battery has been charged first to ensure it is not merely discharged. As to the load tester, this is simply a coil of wire housed in a ventilated metal box. This tool is clamped onto the battery to stress it a given amount and a voltage reading is taken which indicates the batteryís health. It's rather like the stress test a cardiologist gives his heart patient, and it is the only 100 percent reliable way to test a battery. Battery load testers are available in many forms. You can simply go to a good automotive supply and buy an inexpensive wire coil based load tester. Or you can go all the way and spring for a carbon pile job such as a Sun VAT-60, Ferret, or Allen. For my money though, a simple load resistor is all that's really necessary. The air conditioning guys use it, and it works good for you too.

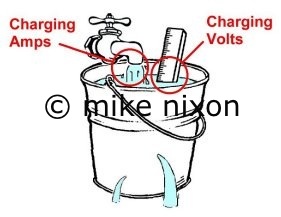

- Q: Why do you insist that charge to the battery be tested in amps and not volts?

A: Volts is not charge. This is pretty important. First, let's understand the difference between amps and volts. Imagine a bucket under a water faucet. Water is rushing into the bucket -- that's amps. As a result of the water's flow, the level in the bucket is rising -- that's volts. The current is amps, the level is volts. Now, which of the two demonstrates activity more clearly, the torrent of water or the rising water level? The torrent, of course. Ití's raw current, whereas the water level is merely the result of that current. The same is true when checking the charging system. When you check it with amps, you are seeing the actual movement of electrical current into the battery. When you check it using volts, you see only the delayed result of that currentís progress. Your information is secondhand, and therefore more susceptible to misinterpretation. Remember also that we talk about accessory loads, that is, the outflow of electrical energy, in terms of "current." Why then, when considering charge, which is simply the reverse, in-flow, of that same current, do some people all of a sudden insist on speaking in terms of volts? It's inconsistent, as well as unprofessional.

- Q: You say the SOHC doesnít charge at idle. Are you sure, and why?

A: The SOHC alternator spins electromagnets near the stator to induce electricity. Though the engine is running, the battery is discharging, not charging. The probable reason manufacturers made them this way is simple economics. It certainly doesn't hurt anything. The bike isn't ridden at idle, and the system in any event starts charging right after idle, so there is no bad result.

- Q: Why does your troubleshooting system have two sides to it?

A: Because dead batteries aren't always the alternator'ís fault. Sometimes an electrical accessory or even the brake light switch is the problem. Two sides are needed because two problems are possible -- Either the battery isnít getting enough charge, or it is losing the charge that it gets, and both must be considered.

- Q: Why must the alternator connector stay connected to check stator output?

A: Because the wires to the electromagnet are in the same connector as the stator's. Disconnecting one disconnects the other. No magnetism, no output.

- Q: Why is the magnetism test done with the engine not running?

A: The regulator energizes the rotor the most (producing the most magnetism) at very low rpm. This includes zero rpm (keyswitch on but engine is not running).

- Q: I have never heard of your way of testing a stator. Why must the stator be loaded, and what is wrong with testing it the way in the official manual?

A: The manual offers two methods, the first of which is a resistance test. Resistance tests are not used by professional techs. They vary considerably with temperature, and the test values are relevant only when using the factory-recommended test meter. Resistance tests should be used only for double-checking, that is, to backup dynamic tests. The second method offered by the manual is a more realistic loaded output test -- the stator is best tested under a load because wire coils often exhibit good condition when relaxed but when put under a strain they fail. However, the manual's loaded stator test has a fault in that the load is the vehicle's own electrical system. Problems in the system (such as a shorted diode in the rectifier) can reduce stator voltage and give inaccurate readings. Therefore the best stator test is a loaded test using an external load.

- Q: What is "a 2 ohm, 100 watt resistor," and why is it necessary?

A: This is a so-called "power resistor" often used in experimental radio work, and as such, is easy to find. This resistor happens to be a good test load for stators, as it simulates the bikeís electrical loads very well, yet keeps the stator isolated from the bike for accurate testing.

- Q: Where do I find a this resistor?

A: Try the following source -- Allied Electronics (Ohmite Solder Lug Power Resistor 2 OHM, 100 WATT).

- Q: How could there still be a problem when the charging system shows there is good charge?

A: See the answer to number 8 above. Two things are responsible for chronic low batteries, given a good battery to begin with. Either the battery isní't getting enough charge, or itís losing the charge that it gets. One is just as common as the other in charging system diagnosis.

- Q: Explain dynamic and static leaks.

A: A leak is merely excessive or unaccounted-for output. A dynamic leak is simply where the battery is losing charge faster than it should. A static leak is where the battery is losing charge when it shouldn't, when the keyswitch is turned off and the engine isn't even running. Labeling leaks either "dynamic" or "static" merely calls attention to whether the keyswitch is on or off, because for each case the troubleshooting steps are different.

- Q: How does the breakeven rpm test tell you whether you have a dynamic or static leak?

A: The SOHC discharges its battery at idle. It therefore has an rpm point at which the battery begins to charge -- that is, output and input "break even". This breakeven point is supposed to happen at a fairly low rpm. Higher than normal breakeven therefore indicates an excesssive discharge problem, for which more engine rpm is needed to compensate. On the other hand, normal breakeven rpm would normally indicate good charging system health, but it doesn't necessarily. Coupled with a chronically low (but tested) battery, normal breakeven indicates a static (key off) leak precisely because nothing in the charging systemís or accessoryís function appears abnormal. The leak therefore has to be happening when everything is turned off.

- Q: How can the brake light affect charge?

A: Older vehicles like the SOHC have fairly low-powered charging systems. As a result, the current going out due to the brake light is rather high compared with the charging current going in. A stuck or misadjusted brake light switch can therefore raise the breakeven rpm so high that at normal road speeds the battery will receive too little charge and get weaker and weaker.

- Q: Why do some electrical components draw current even when the keyswitch is turned off?

A: Clocks, anti-theft alarms, radios, and electronic fuel and engine management circuits are wired directly to the battery, bypassing the keyswitch, because these components have memory and logic circuits that require full-time power. Except for the fuel injection computer, all of these items together should draw no more than 40 mA (1/25 amp).

- Q: Why is the static leak test performed at the battery instead of at the fuse terminals like the amps charge and dynamic leak tests? And, why the negative battery terminal?

A: This test must be performed at the battery simply because a leaky rectifier, the most common reason for static leakage, would not be picked up at the fuse terminals. As for the negative side, this is for safety. It is the traditional way to avoid the sparks that can result in battery explosions.

- Q: What is meant by a "leaky" rectifier?

A: The rectifier connects the stator to the battery directly, without going through switches or any other components. This connection is somewhat tenuous, that is, dangerous. It is supposed to permit current flow in one direction only -- stator to battery, and not battery to stator. However, when one or more of the rectifier's diodes short, the battery's current can then reverse-flow into the stator, depleting the battery while the vehicle is parked. This is not all that unusual, and will result in chronic battery discharge while showing very little sign of charging system malfunction.

- Q: Why doesn't your method include the traditional regulator/rectifier resistance checks?

A: Because "ohmming" the regulator/rectifier is an archaic procedure, and even Honda admits that rarely is reliable. More importantly, it is unnecessary when using live, dynamic tests. For the rectifier, the best test is a stator output test. If current to the battery is low, but the stator outputs strongly, the rectifier is bad. What could be simpler? The rectifier is also tested in the reverse direction in the key-off drain test on the "charge is not low" side of the flowchart. As for the regulator half of the reg/rect, it is tested dynamically by the bypass test.

- Q: Why is the traditional stator test missing in this method, and why isn't it tested first?

A: The stator is tested dynamically in Step Two. As for not being the first test, stators don't fail as often as people think. Although it does happen, especially on certain models such as early Suzukis, Yamahas, Honda V4s and GoldWings, stator failure is the rarest of all charging system parts failures on the majority of motorcycles, including the SOHC four.

Additional questions are welcome.

Email me

© 1996-2015 Mike Nixon

|

®

®

®

®